- New build

- Posted

Norfolk straw-bale cottage aims for passive

Passive house design is often seen as belonging to the world of hi-tech construction — perhaps unfairly, seeing as it emphasises a good building fabric over bolt-on technologies. Straw-bale construction, meanwhile, is usually regarded as the preserve of only the most committed, do-it-yourself eco-builders. To some these two approaches appear to be chalk and cheese, but in fact they are inherently compatible, and more and more projects are now combining the maths-centred approach of passive house with the extensive use of natural materials. In the first of a series of case studies on passive straw-bale dwellings, Lenny Antonelli spoke to architect Fran Bradshaw of Anne Thorne Architects, who designed and built a straw-bale home for herself in Hickling, Norfolk two years ago — and aimed to meet the passive house standard while doing so, with only a single infrared electric panel as the building’s sole active heat source.

Click here for project specs and suppliers

This article was originally published in issue 19 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

Fran, as the architect, project manager and client here, you’ve designed and built one of the UK’s few straw-bale houses that explicitly aimed to meet the passive house standard. What were your overall goals here — and why build with straw-bale?

High performance in building often means sophisticated technology and complex manufacturing, but I think some of the most effective performance in buildings is achieved with minimally processed natural materials.

Natural materials also speak to our senses.

I am interested in the materiality of buildings — what is it actually made of, how do those materials work, what does the building feel, sound and smell like? The acoustic qualities of rooms with timber and clay surfaces are quite different from those created by more highly processed materials, and other senses are involved too. The feel of timber, or the gentle and vibrant colours from light on natural paints, renders and woods are enormously pleasurable. The smell of materials is something we unconsciously respond to. We do not have nearly enough information about how these affect our sense of wellbeing.

Our experience of straw-bale building at the Lordship Rec Ecohub, which Anne Thorne Architects (ATA) designed for London Borough of Haringey, was compelling. People loved doing the straw-bale building. Suddenly in a commercial building programme, there were a bunch of people having fun, sharing the making of something that was going to benefit local people. On completion, people kept saying how beautiful the building was.

This seemed to be a response to a sense of tranquility one has inside the building. The Hickling house project wasn’t really work. I was building a house for myself, family and friends — they could all come and join in making it, and in some way it could also become partly theirs. I wanted to make a lovely place to be, but also it was an opportunity to experiment.

Our design team included myself from ATA, Barbara Jones of Straw Works, Jim Blackburn from the Timber Frame Company, Alan Clarke as services engineer, and airtightness designer Paul Jennings. I was able to choose who to work with on this project, which was a great pleasure. We agreed prices, there was no tendering process, and many contributed to the design as well as to the building.

We wanted to bring together two things people often see as contradictory — high performance technologies and the use of natural materials — to make a house people could enjoy living in. The passive house standard was developed with both comfort and low energy performance in mind. Using the Passive House Planning Package as the design tool, using high tech windows and mechanical ventilation with heat recovery, achieving a high level of airtightness, minimal thermal bridging, and the kind of building accuracy required to achieve all that, is one part. The other part is using the sophisticated and subtle qualities of low embodied energy natural materials in an effective way.

The roof of the cottage is finished with local reed thatch

Can you explain how the straw-bale structure was built exactly?

We proposed a primary framed timber structure, like that we had designed at the Ecohub — but in this case a traditionally designed morticed, tenoned and pegged Douglas fir frame. The straw-bale walls are self-supporting, but the roof and first floor and windows are supported by the primary frame.

The timber sections are 200 x 200mm in order to take the three dimensional pegged joints. Secondary timber members are needed within the straw-bale walls for fixing windows — passive-certified triple-glazed windows are very heavy — and the secondary timbers are in turn supported by the primary frame.

(Clockwise from top left) concreting of the raft foundation, which was insulated with 350mm of EPS; erection of the primary timber frame, which supports the roof and first floor windows; Foamglas insulation was installed at the edge of the raft foundations to prevent thermal bridging here; the timber frame being craned into place on site.

People see straw-bale construction as quite a simple form of construction. However because it is so immensely thick, the issue of supporting windows and doors — also a problem in wide cavity construction — needs to be solved. It depends on timbers built into the wall to provide support for windows. Each straw-bale is bound together with two strings, and these divide the bale into three, so cutting a slot for the structural post has to happen in the centre of the bale. Windows and doors are fixed to these posts in the centre of the straw-bale wall.

In this project the secondary structural timber elements (100x100mm posts) are tied back to the primary frame inside the building through the cantilevered first floor joists and rafters.

As you say, the idea of building a straw-bale passive house in the UK was a bit experimental. Which bits of the experiment would you say worked out particularly well?

What was innovative and worked really well, was designing the structure to incorporate compression plates for the compression of the straw-bales. Bales need to be methodically baled to the right tension as they are cut, and this requires quite a good level of oversight by the farmer, which is why you should be choosy about the bales.

Then they are compressed to achieve a solid wall. It is amazing how wobbly a pile of bales are, and then how strong and solid the wall becomes when compressed. Hazel pins are used each three or four bales high, and three bales apart horizontally, to tie it all together. The first floor joists and the roof rafters were both extended into the wall, with a compression plate fixed to their underside.

The bales could then be compressed downwards, and Barbara from Strawworks uses simple car jacks to do this. Once they have been compressed, the last bale is slid in, and the jacks released.

Secondly we were able to fireproof the roof thatch and use its contribution to the thermal insulation of the roof, by using vapour permeable calcium silicate boards. These were then Tescon-taped on the outside to create the roof airtightness layer.

“It is amazing how wobbly a pile of straw-bales are, and then how strong and solid the wall becomes when compressed.”

Plasterboard would also have been a possible material, but the vapour permeability isn’t so good, and any wetting during building work would have damaged its performance.

And what didn’t work out so well?

What didn’t work so well was our decision to create the airtight layer for the walls on the outside render layer — the final airtightness achieved was 0.87 air changes per hour. It seemed a good idea with this kind of primary frame construction, because of all the internal penetrations from the frame, which has lots of shakes and splits in it (and thank you to those at the International Passivhaus Conference in 2013 who said it was a daft idea, but to try it out and let them know what happens!).

(Clockwise from top left) ’starter’ hazel pins at the base of the straw-bale walls; bales being notched into place around the timber-frame structure; the bales were compressed in place using a conventional car jack; the team laying the bales to construct the walls of the cottage.

The problems were twofold: external tape failure possibly due to a combination of temperature and moisture, and discontinuities in the render layer where the abutting brick walls of the larder and stores were built too close to the straw. Neither of these problems were wholly remediable. In retrospect my view is that an internal airtight layer is required with this kind of construction. The straw needs to be closed to the inside, for fire protection as well as to reduce the number of spiders! We did quite a lot of remedial work internally with burnt sand and linseed oil mastic, which I found to be very flexible and durable.

Hertfordshire-based Good Architecture has recently completed a house using loadbearing straw-bale, which may be easier to make airtight internally — they have achieved passive standard airtightness and passive house certification.

The form of a traditional thatch cottage seems to lend itself well to the passive house standard, which is more easily achieved with simple compact forms, oriented south. What were you trying to achieve in terms of shape, layout and orientation?

It is a very simple plan and building form, and the traditional asymmetrical steeply pitched thatched roof creates lovely spaces inside. Two years later, and with a developing garden around the house, the building sits well in the landscape around it. On the north side, the thatch continues over single-storey brickwork to create a larder outside the thermal envelope, where the temperature is consistently low.

The building demonstrates the age old principle of south-facing windows for deeply penetrating sun in winter. We have made an external pergola to support solar thermal panels and provide summer shade, but in fact the two summers so far suggest that overheating is not an issue — overhanging thatch protects against solar penetration in the summer, and there is almost always a sea breeze here.

The solar gain from windows provides a high percentage of our space heating demand, estimated in PHPP as half the overall heat gains. We’ve been able to use this without any overheating because it is easy to open windows. We have also had a large percentage of solar hot water, something I will be monitoring more accurately this year.

With such extensive use of natural materials, you obviously wanted to ensure these materials were exposed and shown off?

Yes. Seeing the timber frame inside the house reveals the structure. External lime render and internal clay plaster were supplied by Wormesleys who we had worked with previously, but undertaken by an excellent local plasterer who had never used these materials before and was used to achieving very flat and plumb surfaces. He came to enjoy the material and felt that rounded reveals were what worked with straw. I like the contrast externally between the duvet-like form of the render and the mechanical straight lines of windows and stainless steel cills. I was also particularly pleased that we were able to use reed thatch cut a couple of miles away.

Did you learn anything unexpected on the project?

Since building the house, I have become very interested in the acoustic qualities of spaces, and how these unconsciously affect our sense of comfort. Buildings built to the passive house standard are very quiet inside (when windows are shut) because of the airtightness and insulation. All external sounds are so much reduced that internal noise becomes important.

Alan Clarke, services engineer, proposed that the MVHR should be in a partially insulated north-facing shed, and the ductwork designed by Green Building Store was well installed so that the MVHR is almost inaudible. In winter I sometimes miss hearing the birds, and might open a window at night, but mostly I appreciate the comfort and enjoy how little energy is being consumed.

(Clockwise from top left) hazel pins in the straw-bale walls; infill bales around the timber frame structure at first floor level; thatching of the roof by Norfolk Thatchers, who used local reed thatch; Isolair woodfibre insulation and airtightness detailing around windows prior to rendering.

It is the clay plaster and straw-bale wall mass which creates a very different acoustic environment inside. I noticed as soon as we moved in, with very little furniture and furnishings, that the room was not at all echoey, but neither is the sound deadened. It seems the right balance of reverberation and damping is easily achieved with this construction. Musicians who recently played in the ground floor room commented on the excellent acoustics. I think now that the acoustic properties of spaces may be influencing our behaviour much more than we acknowledge or realise.

We’ve heard some people express concern about straw-bale construction in the British Isles before, because of the risk of moisture getting into the structure and causing rot. What’s your take on this?

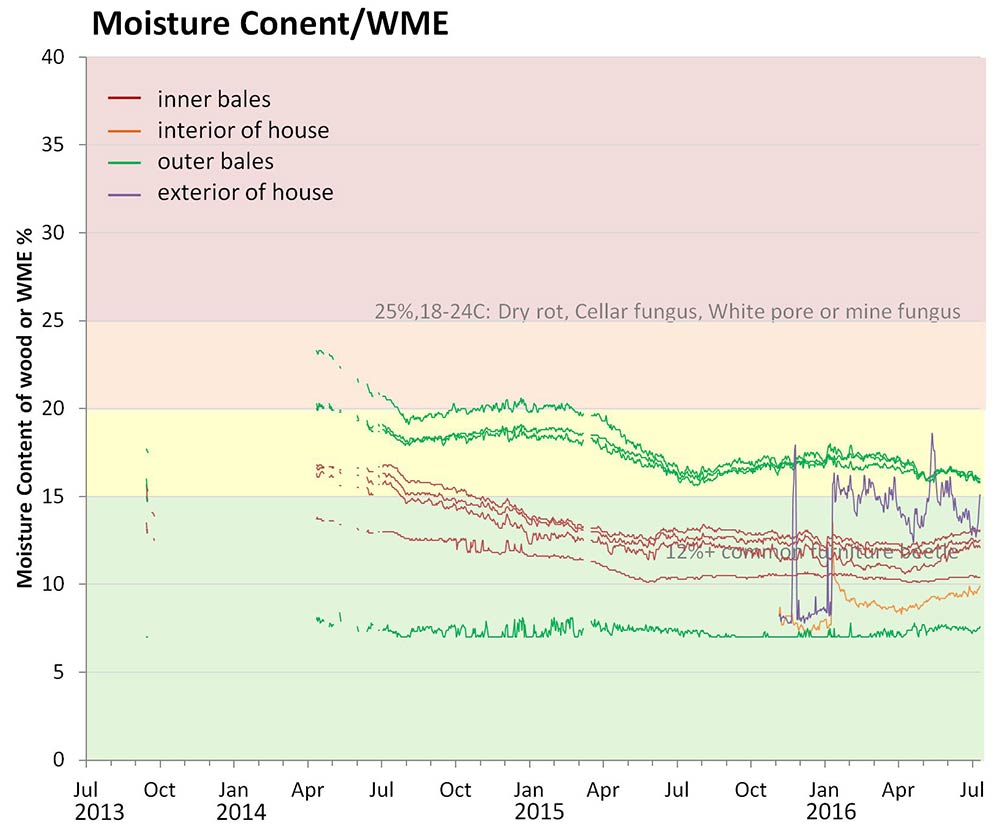

There is very little monitored information on straw-bale wall construction, and in particular we don’t know enough about how moisture affects their long term durability, so we are using the AECB monitoring tool Onmiscense. We installed 10 temperature and moisture sensors in the walls as we built them, with one measuring internally and one externally too.

So far we can see that inner side of bales has dried nicely, well under 15% Wood Moisture E, which means low risk of rot. The outer sides have dried a fair bit over the last two years, but moisture in the outer side of bales in the most exposed areas could potentially be allowing some mould growth.

Post occupancy monitoring including measurements of moisture content, or wood moisture equivalent

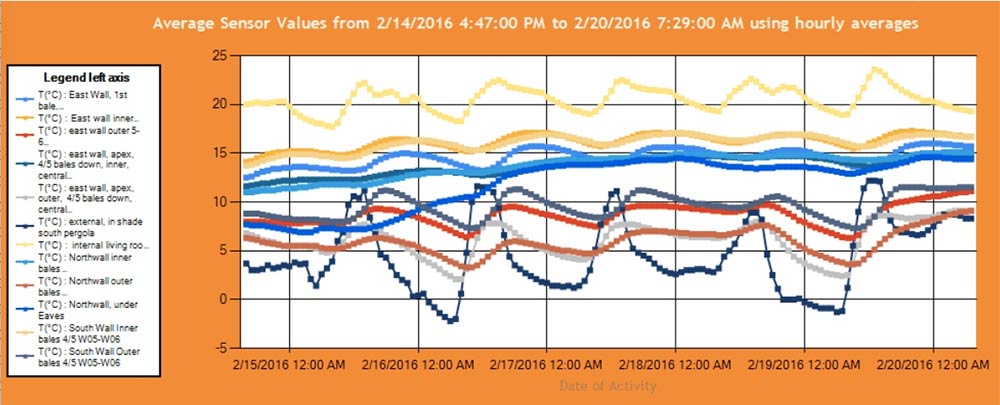

Temperature readings from various parts of the building fabric, externally, and the living room.

On the other hand lime render has a high pH which inhibits growth and the summer figures (when mould growth takes place) show good drying out. We know that there is no risk to structure or windows as they are well embedded. We now have two years of data, and our plan is to keep monitoring another year or so and then do some opening up to see how the physical state is reflected in the data, I’m hoping we will be able to provide good evidence for what the straw-bale experts say — that durability is excellent.

The cottage has been heated mainly by a single infrared electric panel. What was the thinking behind this, and how was it worked out?

I thought we would invest in the fabric and the MVHR rather than a full heating system. There is no gas here, and I didn’t want to spend money on heat pumps or an LPG system when we would need so little heat. Rather, my plan is to invest in some solar PV when we have the money.

We do have a second plug-in heater upstairs, but we’ve hardly used it at all. The bedrooms are slightly colder than average in a passive house during the winter — about 18 or 19C right now.

It’s a fairly minimal setup, but I wouldn’t read too much into it yet because the house isn’t fully occupied. At the moment we’re only here three or four days a week, until moving here full time, so as yet we haven’t tested all the conditions and our heating figures are only approximate. We also haven’t been here for a long, cold period without solar gain. From what we have experienced so far though, the panel heater would keep things going fine.

Selected project details

Clients: Fran Bradshaw & Georg Hermann

Architect: Fran Bradshaw for Anne Thorne Architects

M&E engineer: Alan Clarke

Timber frame: The Timber Frame Company

Passive house designer: Anne Thorne Architects

Structural engineer: Paul Carpenter Associates

Straw-bale design & management: Straw Works

Straw-bales: Longhay / Thompson Brothers

General building contractor: Broadland Builders

Plastering: Danny Rodwell

Mechanical contractor & MVHR: Green Building Store

Airtightness products: Ecological Building Systems, via Green Building Store

Electrical contractor: Sheldon Electrics

Airtightness tester: Aldas

Magnesium oxide boards: Ecological Building Systems

Thatching: Norfolk Thatchers

Cellulose insulation (Warmcel): Payne Insulation

Windows & doors: Optiwin

Lime & clay plasters/renders: Wormesleys

Solar thermal: London Solar

Wood fibre insulation: Natural Building Technologies

Additional info

Building type: Two-storey detached primary frame straw-bale thatched house (TFA 120 sqm, GIFA 133 sqm)

Location: Hickling, Norfolk

Completion date: Occupied from March 2014

Budget: Approx £250,000

Passive house certification: Not certified

because airtightness target not achieved Space heating demand (PHPP): 11kWh/(m2a)

Heat load (PHPP): 11kWh/(m2a)

Airtightness (at 50 Pascals): 0.87 ACH

Energy performance certificate (EPC): B 87

Measured energy consumption (from monitored electricity bills): House is only occupied half the week normally at present, with periods of full occupation, so these are approximate calculations. Taking one three-month period during the summer of 2015, during which the house was fully occupied, shows 180kWh electricity consumption per month, while a fully occupied 2014/15 winter period had electricity consumption of 506kWh per month. This gives an approximate total energy use of 4116kWh per year (six months of each figure), which relates quite well to the total readings and occupation figures. Estimating heating electricity use, by taking the winter figure for electricity consumption and subtracting how water and appliances, gives10kWh/m2, which is pretty much as predicted in PHPP.

Thermal bridging: Due to unusual construction no accredited construction details were used. Where thermal bridging occurs, dealt with as follows, from foundations upwards: Edge of raft foundations: 100mm Foamglass T4, thermal conductivity 0.041 W/mK

Below french window cills: Compactfoam CR200, thermal conductivity 0.046 WmK, density 200 kg/m3.

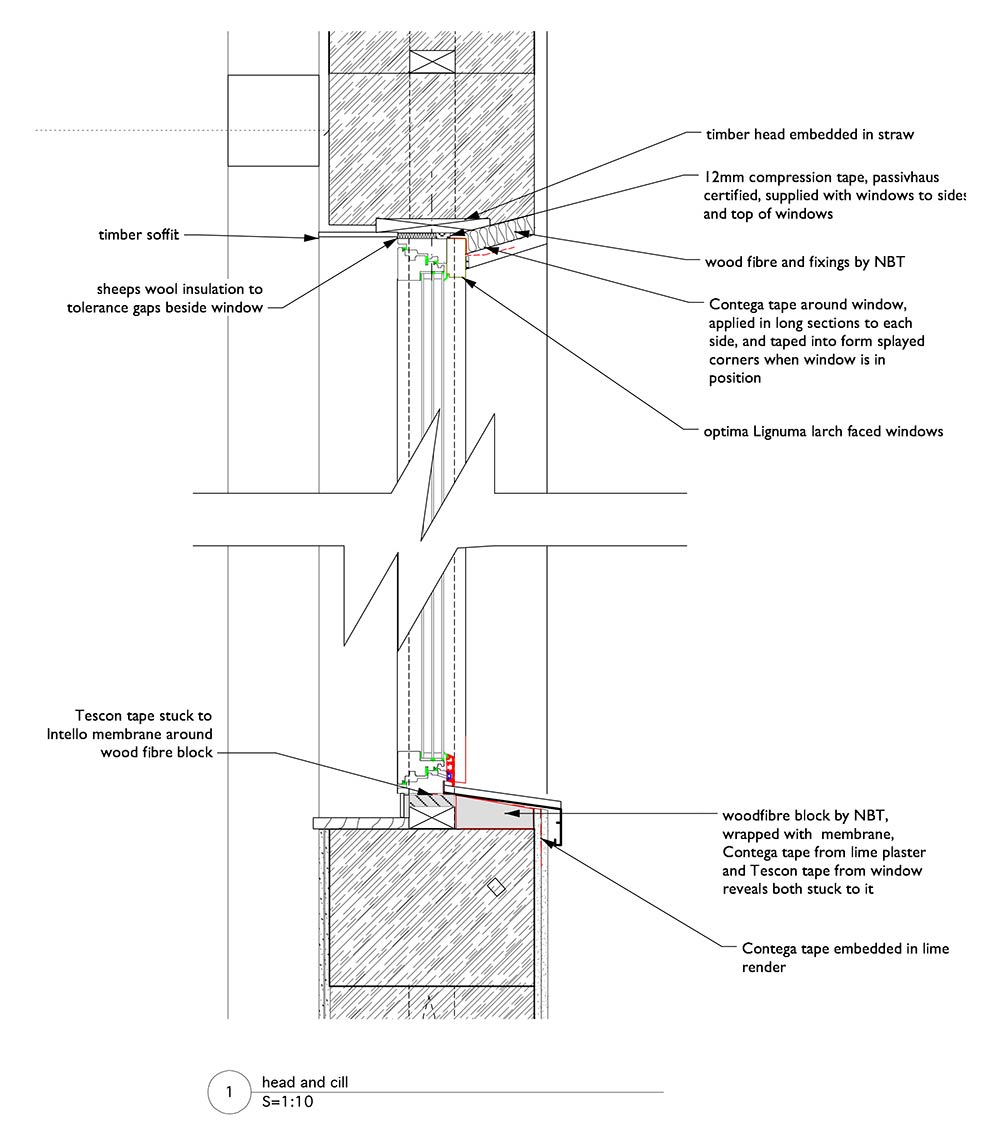

External to door and window frames: 35mm NBT Isolair woodfibre board insulation, thermal conductivity 0.044 W/mK

Ground floor (from ground up): 350mm EPS underfloor insulation (0.38 W/m2K), concrete raft, 50mm Thermafleece sheep’s wool with timber battens between, and 27mm oak floorboards. Overall U-value 0.092 W/m2K

Walls: 30mm 3 coat lime render (0.063 W/ m2K) externally followed inside by 450mm straw-bales (0.052 W/m2K) with straw lying vertically, 3 coat 30mm clay plaster internally (0.066 W/m2K).Overall U-Value: 0.099 W/m2K

Roof: 300mm Reed thatch (0.090 W/ m2K) externally followed inside by air gap and battens, 35mm Isolair wood fibre t&g board (0.47 W/m2K), 12mm multi-pro XS magnesium oxide vapour permeable fire protection boards (0.47 W/m2K), 350mm Warmcel cellulose insulation between I joists (0.47 W/m2K), Glasroc plasterboard and skim. Overall U-value 0.088 W/m2K External brick larder outside thermal envelope, housing MVHR. 215mm stock brickwork with 100mm woodfibre insulation applied internally.

Windows: Optiwin Liguma SuperSp Tri-Seal passive house certified triple-glazed timber windows with larch facing. g-Value 0.57. U-values: glazing 0.58 W/2K, frames 0.81 W/ m2K, glazing edge 0.023 W/mK

Space heating: Single 800W infrared electric panel, solar PV to follow.

Hot water: Indirect sealed pressurised system with 2 x solar TWI T3 flat plate collectors and 75mm insulated 300 litre tank. Short route, insulated pipework from panels to tank. Immersion backup.

Ventilation: Paul Focus 200 heat recovery ventilation system. Passive House Institute certified heat recovery rate of 91%.

Green materials: Straw-bale walls, Douglas fir oak pegged timber frame, magnesium oxide fireboard, Isolair woodfibre insulation, thatched roofing, Wormesleys clay and lime plasters and renders, Warmcel cellulose insulation

-

Section

Section

Section

Section

-

Details Page 1

Details Page 1

Details Page 1

Details Page 1

-

Details Page 2

Details Page 2

Details Page 2

Details Page 2

-

Details Page 3

Details Page 3

Details Page 3

Details Page 3

-

Details Page 4

Details Page 4

Details Page 4

Details Page 4

-

Details Page 5

Details Page 5

Details Page 5

Details Page 5

https://passivehouseplus.co.uk:8443/magazine/new-build/norfolk-straw-bale-cottage-aims-for-passive#sigProIdf392a1a425