- New build

- Posted

Visionary vernacular

Can a low energy building be truly sustainable if it doesn’t fully consider its occupants needs? The latest offering from one of Scotland’s leading green designers uses passive house knowhow to signal the way to pragmatic, modest, occupant-centric architecture.

Click here for project specs and suppliers

House type: 107 m2 bungalow

Method: Wood fibre insulated timber frame infrared heating

Location: Dumfries and Galloway

Standard: AECB CarbonLite Building Standard

Heating & hot water cost: £90/month*

* Estimated space heating and hot water cost, based on Ofgem’s energy price guarantee for October 2022.

See ‘In detail’ panel for more information.

It’s been shown clearly over the last few years that passive house design lends itself relatively easily to a variety of building forms thanks to the versatility of PHPP software.

But every so often, a combination of tight budgets and less than ideal form factors present a challenge that gives even those architects passionate about the standard a reason to rethink their approaches, without jettisoning the efficiency, sustainability, and attention to detail that fully certified passive houses demand.

Beechtrees, a lovely, modest larch-clad, zinc-roofed house in Scotland built by seasoned Dundee-based passive house designer Kirsty Maguire, is one such case.

It’s built to the AECB CarbonLite Building Standard, which is based on passive house and uses the same software (PHPP), but with less onerous targets for energy performance.

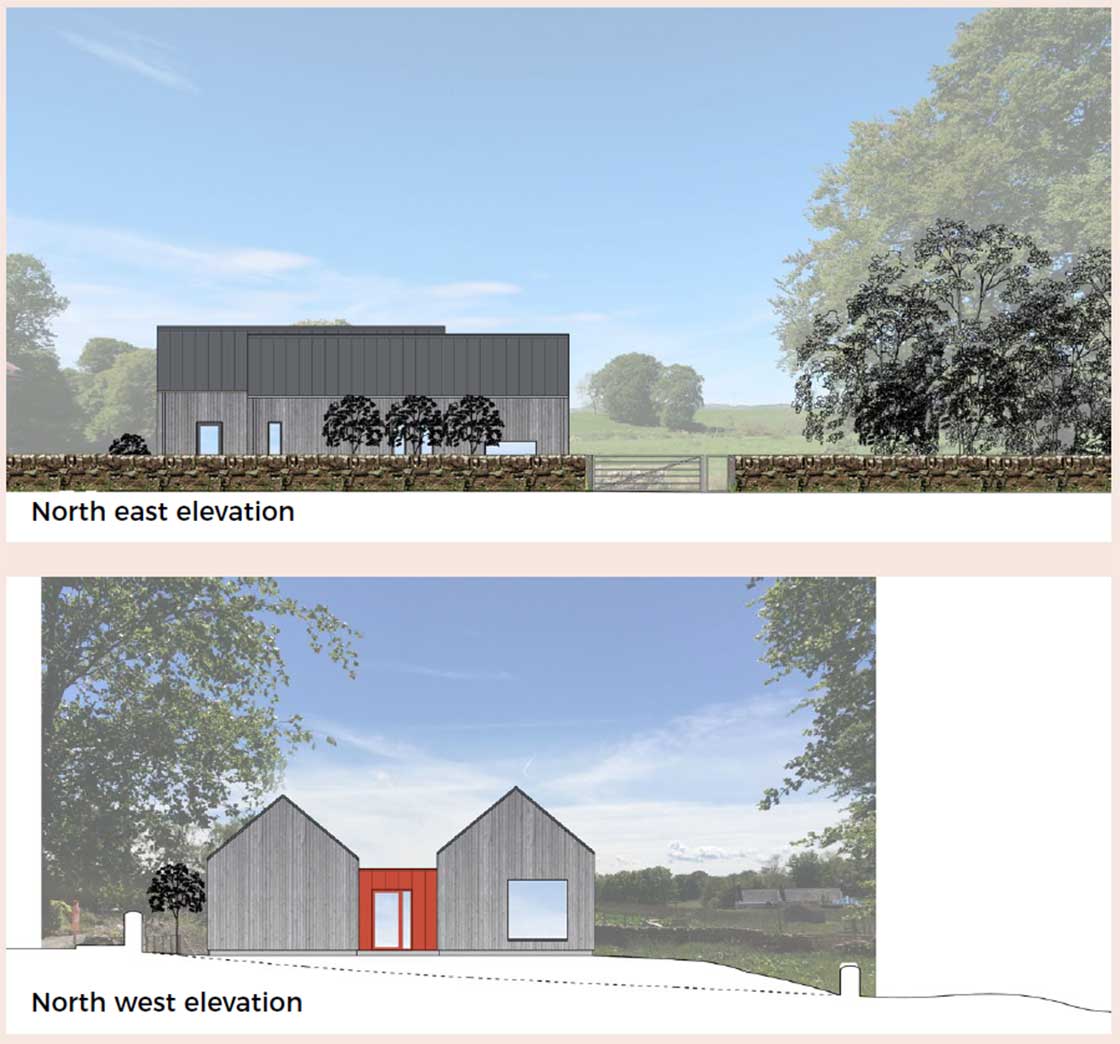

Located in a rural area in the middle of Dumfries and Galloway, a large region in the southwest corner of the country, it’s an unusual and innovative build that doesn’t try to ape a traditional farmhouse, but still strongly reflects the local vernacular of metal roofs and timber cladding of the neighbouring farm buildings.

The inspiration Kirsty Maguire took from around the site is infectious: the link building between the living and bedroom wings has the same colouring as “a beautifully weathered barn with a rust red roof,” and a similar nearby shed.

Built for two retirees, Tony Francis and Zoe Roberts, as their forever home, it’s also single-storey, meaning it will be easier for the couple to navigate in future years. That comes at an energy cost as it increases the building’s surface area to volume ratio or ‘form factor’. Future-proofing the house to allow for the occupants’ changing needs in this case means more walls, roof and ground floor per square metre, and therefore more surfaces through which heat is lost. The form factor is also not helped by the H-shaped floor plan, designed to give the couple two courtyards.

Built for two retirees, Tony Francis and Zoe Roberts, as their forever home, it’s also single-storey, meaning it will be easier for the couple to navigate in future years. That comes at an energy cost as it increases the building’s surface area to volume ratio or ‘form factor’. Future-proofing the house to allow for the occupants’ changing needs in this case means more walls, roof and ground floor per square metre, and therefore more surfaces through which heat is lost. The form factor is also not helped by the H-shaped floor plan, designed to give the couple two courtyards.

It’s designed essentially so that the external spaces are conceived as external rooms, as the clients spend a lot of time outdoors,” said Kirsty Maguire.

The courtyards each exploit the light at different times of day, a bit like a sundial. According to Maguire, the east courtyard, opening from the kitchen, is perfect for sitting outside with a morning coffee. As the sun moves around, it hits the south side with the pond and vegetable garden, bathing the outdoor dining table in sunlight from late morning until evening. It has a generous living space with a cathedral ceiling in the main part of the building. The bedroom wing is similar but more private and set back, and there’s a welcoming entrance space linking the two.

Tony and Zoe were adamant the house shouldn’t be too big for their needs or have any wasted space, and no clutter. “We have no space that’s underutilised, and no junk”.

What the whole space gains inside and outside as a result of this clever design is clearly worth the concession – if you can call it that – of building to the AECB CarbonLite Building Standard instead of passive house.

A quick look at the building fabric specs shows that Beechtrees has exactly what you’d expect to see in a passive house: the U-values for walls, roof, floor and windows, the thermal bridging and the airtightness, and the Zehnder heat recovery ventilation system. It also has infrared heating for the little warmth that’s required and an air source heat pump – using the ultra-low global warming potential (GWP) refrigerant R290 – for hot water.

Named after the mature deciduous trees from the site, Beechtrees is all about timber. As many trees were retained as much as possible, with the felled trees being turned into cills and shelving by a local craftsman. The building’s superstructure is timber frame, with Steico wood fibre insulation in walls and roof, and triple glazed timber windows. The project’s broader sustainability efforts extended into other materials too. Reclaimed materials are used as well, such as paviours, and the drystone dyke was rebuilt by Tony using stone from site. It’s reasonable to argue that if the budget was more flexible, a greater investment in wall insulation, for instance, could have brought the overall energy performance closer to the passive house standard, but other choices took priority, according to Maguire.

“That relationship to the [external] spaces on the site was really key to the layout of the building,” she said. “As a result, we’ve got these two wings and a link, which does make the form factor higher, and therefore there’s a point in time where you can keep putting more and more insulation in but there’s a balance [to be struck]. And that’s where we used PHPP – to start to identify where that balance is, and where you can still get good performance.”

The wall insulation in Beechtrees is far from skimpy, with 240 mm of Steico Flex wood fibre insulation fitted between the timber frame, with a further 100 mm of Steico Special Dry wood fibre boards wrapping the frame externally, delivering a U-value of 0.127. Nonetheless the design allows for more: an extra layer of insulation could be installed very easily by simply removing the timber cladding at some point later, giving this dwelling a highly satisfying degree of cheap and easy future-proofing.

Besides the lower energy targets, the key difference between the AECB and the passive house standard is around certification.

We needed a mud room for the dogs – a place where three filthy Labradors can go and shake.

In a nutshell, certification for a passive house can only be awarded by an independent certifier, while the AECB relies on self-certification by the designer or consultant.

According to the AECB website: “The AECB self-certification process is designed to make explicit the project’s claim to be a low energy design and to provide the consumer with a degree of protection under trading standards – without the AECB having to get involved in quality control and legal matters. “This approach puts the responsibility for performance claims clearly with the person signing the certificate and a duty of care on the client to ensure that the consultant is competent and suitably insured.”

Kirsty Maguire herself is a big advocate of passive house certification, and recently undertook passive house certifier training, becoming the only Scottish-based consultant to have this. Having designed several certified passive house projects over the last decade, Kirsty says with Beechtrees she made sure the quality assurance process was the same, along with the details and the general approach to the project.

Which was surely music to the ears of Tony and Zoe, who were introduced to the passive house concept by their daughter, and were inspired enough to make enquiries that quickly led them to Maguire’s door and the start of an in-depth but by all accounts very amicable and free-flowing discussion about what they wanted. Their brief was for an environmentally sustainable and warm home that maximised the access to the outdoor space around the site so that they could enjoy the garden and walk their dogs and entertain family, and also recycle as many of its elements as possible.

“There were quite a lot of things we put on the brief,” says Zoe, “such as being able to have the doors open when we’re cooking, and positioning the house so we could make the most of the private bit of garden… we needed a mud room for the dogs – a place where three filthy Labradors can go and shake.”

They were also adamant that the house shouldn’t be too big for their needs or have any wasted space. “I think we were very keen to have no clutter. We were ruthless before we moved in about throwing things out that hadn’t been used. And thankfully we have no space that’s underutilised, but neither do we have any junk.”

This article was originally published in issue 44 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

Kirsty’s experience and a highly communicative approach to working with Zoe and Tony, allied with the enthusiasm and commitment of a local contractor undertaking one of his first passive house-informed projects, meant that Beechtrees succeeded – even exceeded – expectations in terms of meeting their quite specific demands.

“Kirsty is so kind of efficient and pedantic, in the nicest possible way, about detail that she and her assistant really pushed us hard to make decisions before it even got out of the ground, such as things about light switches, outside lights, positioning of inside lights, colour of the kitchen, colour of the tiles,” said Zoe, who even admits to getting a “wee bit stressy” about it as the process went on, “but oh my goodness, did we realise the value of that during the build”.

They’re also full of praise for Kirsty’s choice of contractor, David Broatch of Broatch Construction, a firm based just 20 miles away, even though he had limited previous experience of working on passive houses. “They had never built a house like this before, and... Kirsty must have had some intuition about them,” said Tony, who was sceptical that they would take on the job with the limited budget they had, “but she was right. They really wanted to get it right. And they concentrated so hard on doing that.”

It was clearly a transformative experience for Broatch, because he has gone on to completely change his business focus as a result of this project, heading into passive house in a big way. The firm has recently completed building a home for the daughter of wellknown passive house architect Jonathan Hines, managing director of Architype, on the strength of Kirsty’s recommendation.

Adding to the highly positive build experience was the efficient sourcing of materials just before the chaos of the Covid pandemic, so that the only supply issue was bathroom tiles, which Tony and Zoe sourced elsewhere in order to keep to the schedule. Only the windows and doors were a little late, but this added just three weeks to the projected 16-week build time.

The choice of timber frame construction was a simple decision given timber frame’s dominant position north of the border, so expertise and skills were easy to find.

“We’ve got obviously great joiners across everywhere who are familiar with it so it’s a sort of standard way of doing things up here for buildings at this scale." Kirsty also describes Beechtrees as a bit of a dream project. “We had great clients, really fantastic to work with, really good at making decisions, and great ideas. We also had really good colleagues in the design team so we could work together quickly in a straightforward way.

“And then working with the contractor was fantastic,” she added. “They would come to us with the potential of how to make things even better than we had so we can learn from them as well and keep that discussion flowing. The work that they did was in accordance with drawings and beautifully done, and it was on time, on budget during Covid. I’m not quite sure what more we could have asked for really.”

It’s rare that a client is less than delighted with any project worthy of being featured in this magazine, but Tony and Zoe exude a particular pride in what their two-bed home represents in terms of its modesty, efficiency, sustainability and, above all, a dwelling that’s tailor-made for them right down to the last detail and with no attic or any kind of wasted space. And of course, a very comfortable home.

-

The house is named after the mature deciduous trees from the site

The house is named after the mature deciduous trees from the site

The house is named after the mature deciduous trees from the site

The house is named after the mature deciduous trees from the site

-

Isoquick insulated foundation system and timber frame

Isoquick insulated foundation system and timber frame

Isoquick insulated foundation system and timber frame

Isoquick insulated foundation system and timber frame

-

400 mm Steico Flex wood fibre insulation in the bedroom wing

400 mm Steico Flex wood fibre insulation in the bedroom wing

400 mm Steico Flex wood fibre insulation in the bedroom wing

400 mm Steico Flex wood fibre insulation in the bedroom wing

-

Airtightness taping at window

Airtightness taping at window

Airtightness taping at window

Airtightness taping at window

-

Heat recovery ventilation ducts in void inside airtight layer

Heat recovery ventilation ducts in void inside airtight layer

Heat recovery ventilation ducts in void inside airtight layer

Heat recovery ventilation ducts in void inside airtight layer

-

Threshold detail

Threshold detail

Threshold detail

Threshold detail

-

Salvaged tiles

Salvaged tiles

Salvaged tiles

Salvaged tiles

-

Salvaged tiles

Salvaged tiles

Salvaged tiles

Salvaged tiles

-

Greencoat PLX standing seam roofing system

Greencoat PLX standing seam roofing system

Greencoat PLX standing seam roofing system

Greencoat PLX standing seam roofing system

https://passivehouseplus.co.uk:8443/magazine/new-build/visionary-vernacular#sigProId507fb4d52f

Having lived all their lives in old houses with nooks and crannies, big sandstone walls that Tony describes as “just big sponges full of water”, they now live in an “almost perfectly controlled environment”.

“We’ve got the air circulation system in the heat exchanger, which brings in fresh air, collects the warmth from the house and pumps out the stale air. We’ve got fresh air to breathe; even if we don’t open a single door or window, we’ve got lovely fresh air, of the right temperature.”

They’re particularly pleased with the work of a local furniture maker, Philip Wilson, who cut down the beech tree that obviously inspired the house’s nomenclature and then created beautifully rustic shelves and windowsills with the wood, all finished with a very distinctive blue resin. “It’s terribly, terribly original and just so beautiful to look at.”

Viewed purely from an energy performance perspective, Beechtrees could have pushed the envelope a little more with still more insulation or a more compact form. But energy performance and thermal comfort are not the only requirements to consider, and this thoughtful, skilfully designed house makes a strong case for allowing a little leeway, and is tailored to meet the needs of its owners throughout their later years.

Selected project details

Client: Zoe Roberts and Tony Francis

Architect: Kirsty Maguire Architect Ltd

M&E engineer: Luths Services

Civil/structural engineer: Narro Associates

Energy consultant: Kirsty Maguire Architect Ltd

Main contractor: Broatch Construction

Quantity surveyors: McGowan Miller Construction Consultants

Mechanical contractor: Paul Heat Recovery Scotland

Airtightness tester/consultant: Thermal Image UK

Wood fibre insulation: Steico, via Ecomerchant

Insulated foundations: Isoquick

Airtightness products: Ecological Building Systems

Windows and doors: Green Building Store

Flooring: Howdens

Roofing: Greencoat PLX

Infrared panels: Trotec

Hot water heat pump: Vaillant

Mechanical ventilation: Paul Heat Recovery Scotland

Heating controls: Heatmiser

In detail

Building type: Single-storey detached property. TFA 107 m2

Site type & location: Site in a hamlet on the outskirts of Thornhill village, Dumfries and Galloway

Completion date: February 2021

Budget: £261,000

Number of occupants: 2 adults and 3 dogs

Energy performance standard: AECB CarbonLite Building Standard

Space heating demand (PHPP): 32 kWh/m2/Yr

Heat load (PHPP): 17 W/m2/yr

Primary energy renewable (PHPP): 87 kWh/m2/yr

Overheating (PHPP): 2 per cent of year above 25 C

Energy performance certificate (EPC): B82

Airtightness: 0.42 ACH @50pa

Embodied carbon: Not calculated. Similar to Dundee passive house published in issue 38 of Passive House Plus, although without the PV array.

Energy costs: Total metered electricity usage in first year for all uses of 6,087 kWh. Assuming the current average electricity energy guarantee for Great Britain of 34p per kWh of electricity, with a daily standing charge of 46p, the total household energy bill for all uses would be £2,237/yr. As metered data wasn’t available on space heating, two options were available for deducing heating use: the PHPP-calculated space heating demand of 32 kWh/m2/yr multiplied by the building’s treated floor area, which would translate to 3,424 kWh/yr for space heating alone – a figure that is likely too high, given the measured whole building total of 6,087 also includes hot water, fans, lighting and all unregulated loads (i.e. plug loads). Therefore, Ofgem UK average electricity use for a two or three-person home of 2,900 kWh/yr (for homes with gas heating) was instead deducted from the measured total, leaving an estimated total for heating and hot water of 3,187 kWh. This comes to a total of £90 per month for space heating and hot water.

Thermal bridging: Not modelled due to costs, so punitively high values were used in modelling to be conservative. Key thermal bridging mitigation measures included an insulated slab with edge detailing, wood fibre insulation layer external to the timber framed walls and roof, windows overclad with insulation on the frame, and rainscreen cladding meaning no blockwork or ties. Thermal bridges through fabric were avoided through design.

Ground floor: 200 mm reinforced concrete slab; 250 mm Isoquick insulated foundation system; Visqueen CPT DPC (jointed to DPM and lapped up over sides of 2-layer 100 mm Isoquick insulation upstand at perimeter); 50 mm screed; Howden’s engineered oak flooring. U-value: 0.095

Walls: 12.5 mm plasterboard; 50 mm uninsulated service void; Pro Clima Intello Plus airtight membrane; 9 mm OSB racking board; 240 mm timber frame fully filled with Steico Flex wood fibre insulation (140 mm + 100 mm); 100 mm Steico Special Dry wood fibre board; 50 mm vented cavity; locally sourced larch timber cladding on battens and counter battens. U-value: 0.127

Living wing roof: Pitched roof cathedral ceiling featuring 12.5 mm plasterboard; 50 mm uninsulated service void; Pro Clima Intello Plus airtight membrane; 9 mm OSB; 300 mm I-joist rafters fully filled with Steico Flex wood fibre insulation; 100 mm Steico Special Dry wood fibre board; 50 mm vented cavity; 23 mm softwood sarking board; Isomat Pro membrane; Greencoat PLX standing seam roofing system. U-value: 0.110

Bedroom wing: Trussed roof featuring 12.5 mm plasterboard ceiling; 100 mm service void to allow for MVHR ductwork; Pro Clima Intello Plus airtight membrane; 9 mm OSB; 400 mm Steico Flex wood fibre insulation (4 x 100 mm batts, laid perpendicularly) between trusses; with ventilated cold roof above. Pro Clima Quatro membrane to lap between trusses and over 300 mm of Steico Special Dry wood fibre board where wall extends into roof space; 100 mm Steico Special Dry wood fibre board. Roof trusses on pitch; 23 mm softwood sarking board; Isomat Pro membrane; Greencoat PLX standing seam roofing system. U value: 0.097

Flat roof (above entrance hallway and utility): Warm roof featuring 12.5 mm plasterboard; 200 mm service void; Pro Clima Intello Plus airtight membrane; 9 mm OSB; 175 mm timber rafters; 18 mm plywood deck; Visqueen vapour barrier; 200 mm PIR insulation; 18 mm plywood deck; and Sika Trocal Type S membrane, with waterproofing lapping up to the wood fibre in the adjacent wing roof sections. U-value: 0.117 Windows & external doors: Green Building Store Performance range timber windows and doors with uninsulated frames. Class 4 airtightness ratings, and FSC certified pine. Uw-value: 0.85

Heating system: Trotec infrared heating panels, with a Vaillant Arostor 200 domestic hot water heat pump for hot water only.

Ventilation: Zehnder ComfoAir 350 heat recovery ventilation system. Passive House Institute certified efficiency at 84 per cent. Water conservation: Water butts for rainwater harvesting from roof for garden. Low flow rate taps, WC and showers.

Sustainable materials: Timber frame, wood fibre insulation, reused/recycled paving slabs, beech from tree on site used in joinery finishes from local craftsman, rebuilt drystone wall in the garden.