- Upgrade

- Posted

From derelict shop to tiny low energy home

In 2014, one couple decided to give up life in a van and convert an old newsagents in Shrewsbury into a very small low energy home, using the principles of the passive house standard as their guide. So how did it work out, and what is life really like in such a small home?

Click here for project specs and suppliers

Building type: Derelict shop converted into 45 sqm home

Location: Shrewsbury, England

Budget: £37,000

Standard: Enerphit (indicative)

£125 space heating bill (PHPP estimate)

When architect Clare Williamson and her structural engineer husband Oscar Baldry moved into their tiny low energy house in Shrewsbury back in 2015, it seemed large compared to what they had been used to.

The pair had just spent 18 months living in a panelled builder’s van in the UK — nine months exploring the whole country, and the rest of the time parked outside the derelict newsagent’s they had bought to retrofit in the Shropshire medieval town.

After such confinement, the 42 square metres of ‘Beehive’, as they dubbed it, represented untold luxury.

It is true the decision to purchase such a small property came partly out of necessity.

They wanted to get on the housing ladder and could afford little more. However, it also accorded with their personal values.

This article was originally published in issue 24 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

They had watched many videos about the tiny house movement, which had begun in the US as a reaction to rising house prices and the ever-expanding size of American houses. The concept was starting to take off in the UK too, with developments such as Abito’s 32.8 square metre ‘intelligent living spaces’, in Manchester.

“We loved tiny house as it fitted in with where we were coming from,” Clare says.

“Not only had we spent a lot of time living in a van in the UK, and also New Zealand, we’d also just come back from backpacking around the world and living in a tent. In the developing world, we’d seen how people make do with very little. We often slept in tents, and later lived in another van for nearly a year in New Zealand. Having spent so much time in a confined area, we realised we didn’t need a lot of space or material items. After we moved into the Beehive, it seemed very large!”

The tiny house movement… had begun in the US as a reaction to rising house prices and the ever-expanding size of American houses.

The journey to their new life in Shrewsbury began in 2011 when Clare and Oscar quit their jobs in London and set off on their travels.

After returning home in 2013, they decided they did not want to return to London, and set off to explore their home country. At first, they considered a new life in Wales, but Oscar then found a part-time job in Shrewsbury, and they fell in love with the quaint old town.

They found the derelict newsagent’s on sale for £50,000, but it had been refused planning permission twice due to proposed overdevelopment. They offered £33,500 subject to planning permission, and the owner snapped their hands off.

After getting the keys in February 2014, they set to work with Clare as full-time project manager, living out of the van parked in the front yard.

The decision to retrofit the Beehive using the principles of passive house design was taken near the outset. Clare had attended a training programme in sustainable building skills in Germany in 2013, and decided to pursue full passive house consultant training in 2014. The Beehive project developed into a test bed for passive house principles.

“We both wanted to be sure we understood the rigours of the passive house standard and to see if the end result was something we liked living in, before suggesting it to clients. The experience armed us with lots of useful nuggets and convinced us it was worth it. Above all, we love having a cosy house that is full of light and fresh air,” she says.

The Beehive was a true self-build, with the couple carrying out 90% of the work.

Clare made sure all building materials were ready on Thursday evening when Oscar returned from work and they spent three-day weekends, and evenings, working on the house.

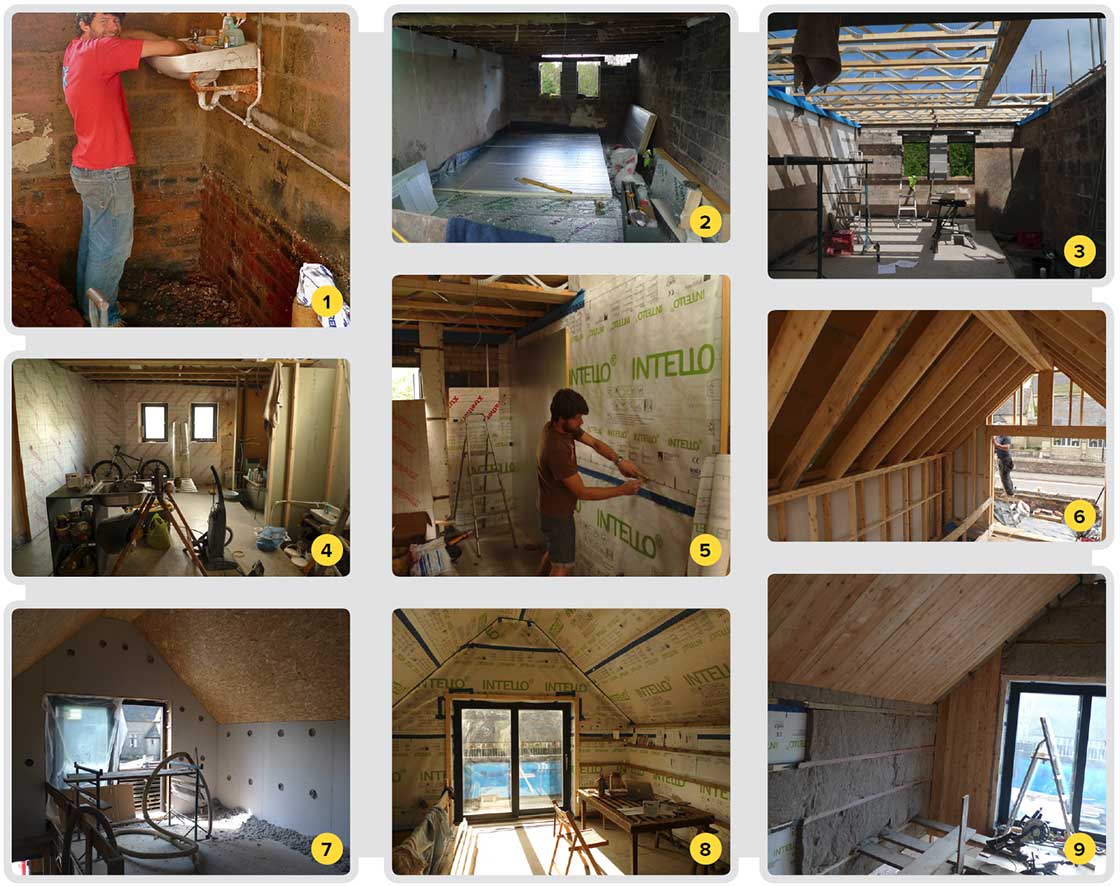

1 Oscar Baldry getting down to work in the old newsagent’s shop; 2 laying Kingspan and Ecotherm insulation in the ground floor of the old shop; 3 first floor metal web joist detailing, with membrane behind the joists for airtightness; 4 ground floor walls feature 50mm Xtratherm internal insulation; 5 this is followed inside by an Intello vapour control barrier and a further 25mm Xtratherm; 6 the new timber frame first-floor twin-stud walls and roof rafters are of a fully breathable construction and full-filled with Warmcel cellulose insulation; 7 holes in the timber-frame where the Warmcel insulation was pumped in; 8 a pro clima Intello membrane on the inside of the first-floor walls and roof; 9 and finally, 50mm Thermafleece (sheep wool) lined service cavity to the interior.

1 Oscar Baldry getting down to work in the old newsagent’s shop; 2 laying Kingspan and Ecotherm insulation in the ground floor of the old shop; 3 first floor metal web joist detailing, with membrane behind the joists for airtightness; 4 ground floor walls feature 50mm Xtratherm internal insulation; 5 this is followed inside by an Intello vapour control barrier and a further 25mm Xtratherm; 6 the new timber frame first-floor twin-stud walls and roof rafters are of a fully breathable construction and full-filled with Warmcel cellulose insulation; 7 holes in the timber-frame where the Warmcel insulation was pumped in; 8 a pro clima Intello membrane on the inside of the first-floor walls and roof; 9 and finally, 50mm Thermafleece (sheep wool) lined service cavity to the interior.

When they finally completed it in May 2015, they were able to move into a comfortable one-bedroom property where everything has its place. The entrance leads into the kitchen, and the bedroom is at the back on the ground floor. Upstairs, there is a dual living and working space that opens on to a little terrace at the front.

The couple specified internal insulation to the existing walls on the ground floor, although it was not their preferred method.

Clare says they had no option on the ground floor because on three sides of the building, the external walls formed the boundary of ownership. “We had to sacrifice quite a lot of space to create the insulation and make a very warm house, but I’m glad we did,” she says.

Insulating walls internally generally carries more risk of mould, because it can create a ‘dew point’ where water vapour condenses on the cold surface of the original wall, behind the new insulation, where there is a sudden drop in temperature.

Unfortunately, with their strict budget, the couple could not carry out dynamic condensation calculations as part of the design. Shrewsbury is in a moderate risk area in terms of exposure to wind-driven rain, according to the BRE, which may help matters.

Instead, the couple’s approach was based on their best judgment at the time. Clare carried out basic calculations that informed the decision to split the internal PIR insulation into two layers, sandwiching a vapour control layer between the insulation boards.

This, together with the heat recovery ventilation system, the bead insulation installed in the original wall cavity (which keeps the inner wall warm), the repointing of joints, and the sheltered nature of the site, all help to mitigate the risk of interstitial condensation. The couple also added a second vapour control layer in the shower room.

The tiny house movement… had begun in the US as a reaction to rising house prices and the ever-expanding size of American houses.

By contrast, the new timber frame first-floor walls and roof are of a fully breathable construction consisting of a twin-stud wall filled with Warmcel cellulose (recycled newspaper) insulation.

The building scored an impressive airtightness test result of 0.5 air changes per hour at 50 Pascals – a score that not only blitzes the requirement for Enerphit (the passive house standard for retrofit), but comfortably beats the new build passive house target of 0.6 ACH too.

Just two 400W radiators now heat the house and a 55W towel rail paid for through a renewable tariff. Monitoring shows fairly constant 45% humidity inside (between 40% and 60% is considered healthy) and the temperature at around 21C.

Clare says the house has served its purpose as a testing ground, and she cannot speak highly enough of passive house to clients who approach the couple’s practice, CandO Design.

“Having grown up in a large draughty Northern Irish house where heating was used sparingly, I love living in comfort without feeling it’s costing the earth. I must say that my idea of comfort is changing though. I used to be hardier, but I’m gradually turning into a big softy.”

Living in a tiny house: is it for everyone?

by Clare Williamson, Beehive architect & homeowner

Living in tents, vans and then the Beehive has worked extremely well for my husband and I as each have been appropriate to our needs at the time.

But I think true tiny houses, smaller than ours, are only healthy where one’s lifestyle involves spending a lot of time outdoors or elsewhere, as we did when we lived in the van.

Of course, everyone has different relationships and so called ’needs’ so I think being able to do this is a very personal thing related to one’s values. The addition of good design and comfort is also critical to small living.

We like how living in small spaces has constrained us from acquiring unnecessary material possessions or simply stuff that isn’t used. Other people might hate this.

The Beehive is larger in scale than a true tiny house and is completely adequate for us to live a very comfortable healthy lifestyle and have friends around for a meal. This is partly to do with the high level of space efficiency and storage. The main limitation we have found is we would like a spare room rather than sofa bed so family feel they can stay longer. But I don’t think this is insurmountable if a group of small houses had a shared rentable house nearby.

Selected project details

Clients: Clare Williamson & Oscar Baldry

Architect & furniture: CandO Design

Structural engineering: Bob Johnson

Structural Engineers (Oscar Baldry)

Airtightness test: Encraft

Cellulose insulation: Warmcel/PYC Systems

Airtightness products: Ecological Building Systems, via PYC Systems

Floor insulation: Kingspan Insulation UK & Ecotherm, via Seconds & Co

Internal insulation: Xtratherm

Cavity insulation: Instabead

Windows: Rationel, via European Window Systems

Bespoke window: Manleys Joinery

Passive door: James Latham Ltd

Ventilation: FIS Heat Recovery Ventilation

In detail

Building type: Conversion & extension of derelict 1960 newsagents into two-storey, 45 sqm house

Location: Longden Road, Shrewsbury, Shropshire

Budget: £37,000 (incl all build costs but not planning, legal fees and affordable housing contribution). The site cost an additional £33,500.

Space heating demand (indicative PHPP calcs): 20 kWh/m2/yr

Heat load (indicative PHPP calcs): 14 W/m2 Primary energy demand (indicative PHPP calcs): 220 kWh/m2/yr

Overheating frequency (indicative PHPP calcs): 10% of year above 25C

Form factor (surface area of thermal envelope / treated floor area): 4.5

Energy performance certificate (EPC): C 73 (due to electric heating/hot water)

Measured energy consumption: 82.5 kWh/m2/ yr (based on bills Jan to July 2015)

Energy bills: £800/yr on electricity including all heating, hot water and cooking (based on bills Jan to July 2015). £125 per year for space heating (PHPP estimate).

Airtightness (at 50 Pascals): 0.5 air changes per hour

GROUND FLOOR

Before: Approximately 70mm concrete.

After: 150mm blinded hardcore; DPM; 200mm Kingspan/Ecotherm insulation; second DPM to contain slab; 100mm reinforced concrete to finish – ground down to expose aggregate – with 75mm perimeter PIR insulation to upstands. U-value: 0.11 W/m2K

GROUND FLOOR WALLS

Before: Brick-block cavity walls with empty 70mm cavity. U-value: 1 W/m2K

After: 70mm Platinum EPS bead insulation to cavity, followed inside by 50mm Xtratherm internal insulation, vapour barrier, 25mm Xtratherm insulation. U-value: 0.16 W/m2K

First floor extension walls: 270mm twin-stud timber frame walls full-filled with Warmcel. Fermacell with pro clima Solitex Fronta Quattro membrane fully taped and sealed as wind-tightness membrane to the exterior. Plasterboard, pro clima Intello airtightness membrane and 50mm Thermafleece (sheep wool) lined service cavity to the interior. U-value: 0.12 W/m2K.

New roof: Clay tiles externally on 50x35 battens and counter-battens, followed inside by pro clima Solitex membrane, 25mm wood fibre on 290mm rafters full-filled with Warmcel insulation, 11mm OSB, pro clima Intello membrane and 50mm Thermafleece-lined service cavity to the interior. U-value: 0.10 W/m2K

WINDOWS & DOORS

Before: Single glazed, timber windows and doors. Overall approximate U-value: 3.50 W/m2K

New triple glazed windows: Rational Aura Plus timber aluminium triple glazed, argon-filled windows. Average U-value of 1.05 W/m2K.

Bespoke timber window: Triple glazed, argon-filled window from Manleys Joinery, with warm edge spacer. U-value: 0.80 W/m2K

Entrance door: Passive House Institute certified Moralt FERRO Passiv timber door, with insulated core and 10 year guarantee against bowing. U-value: 0.80 W/m2K

Heating: 2 x 400W Adax electric heaters and 55W electric towel heater to bathroom Ventilation: Titon HRV1.25 heat recovery ventilation system, non certified heat recovery efficiency of 91%

Green materials: Warmcel and sheep’s wool insulation used where suitable, Osmo oil finish to all wood floors/birch ply walls/ kitchen, bed from the ‘freecycle’ network, with all free standing furniture being hand-me-downs from family or Gumtree with the exception of a yellow metal chair.

Exactly how much energy does the Beehive use?

Although the Beehive did not quite meet the Enerphit (passive house retrofit) standard based on calculations done by Clare when the building was completed, there is reason to believe that it would fare better if re-assessed.

Following the efforts of passive house consultants Nick Grant and Alan Clarke to prove that PHPP, the passive house design software, may have previously underestimated the benefits from internal heat gains in smaller buildings, the latest version of PHPP has been updated to address the issue.

And in this case it seems to have delivered: a broad brushstroke analysis kindly provided by Nick Grant for this article shows that when re-calculated using the new PHPP, the Beehive’s space heating demand dropped to 20 kWh/m2/ yr, comfortably inside the Enerphit target of 25, while the building appears to have avoided exceeding the overheating target (not to exceed 25C internally more than 10% of the time) by the skin of its teeth.

But in spite of this, it appears to fall short of one key target: the calculated primary energy total of circa 220 kWh/m2/yr is well over the passive house target of 120.

And the house’s monitored energy performance appears to match the calculated figures, working out at 226 kWh/m2/yr worth of primary energy. This assumes the same primary energy factor used in PHPP: each kilowatt of electricity used in the building represents 2.7 kilowatts of primary energy, principally due to inefficient power generation. But this apparent correlation does not tell the full story.

There is one glaringly obvious reason why the Beehive might have such high primary energy demand: the hot water is heated solely by an electric immersion, and with thermostatic control, meaning the tank is constantly kept hot in spite of Clare and Oscar’s apparently parsimonious hot water use.

There is also the effect of the building’s small size, which is penalised in PHPP. As Nick Grant points out, if the home’s treated floor area clocked a more typical 120 sqm rather than 40 sqm, much of the energy load – the likes of computers, kitchen appliances and bathing – would be divided by three times the area. The monitored energy use figures work out at 3,519 kWh per annum at the electricity meter, or £521 (excluding standing charges and levies) based on the comparatively high unit price of £0.15p that Clare and Oscar pay for guaranteed renewable electricity supply. But as Clare explains, there are a number of factors which may be conspiring to inflate those figures.

Firstly, Clare works from home, meaning attendant additional energy use. “A laptop, screen and printer are working most of the time,” says Clare. “We Airbnb the property intermittently (at one stage we had a couple stay there for 2 months) so we have no idea of their usage, and I have been doing more washing than normal due to doing holiday lets on this and another property.”

Though the couple bought second-hand appliances with “decent ratings”, Clare suspects a faulty small freezing compartment in the fridge may be an energy culprit, with guests often not closing it properly.

Arguably, there may be little point in comparing predicted versus measured total energy use in an individual home in this kind of detail, because the two figures are unlikely to be making the same assumptions about usage. Space heating in a passive house may be something of an exception in this regard, in that the scope for usage fluctuation is reduced by all but eliminating the need for space heating. But people don’t tend to lead identikit lives, so often wildly divergent behaviours mean that to draw accurate conclusions about typical total energy use (i.e. including electrical and hot water consumption as well), data from large numbers of buildings may be required.

With regards to primary energy, in real terms Clare and Oscar’s decision to go with a renewable electricity supplier may mean the actual primary energy use is substantially lower than the grid average. Given that this is a personal choice that could be overturned by simply switching supplier, it is sensible that this is not part of the consideration in determining a building’s energy or carbon impacts.

Image gallery

-

First floor layout plan

First floor layout plan

First floor layout plan

First floor layout plan

-

Ground floor layout plan

Ground floor layout plan

Ground floor layout plan

Ground floor layout plan

-

Ground floor rear window

Ground floor rear window

Ground floor rear window

Ground floor rear window

-

Section 01

Section 01

Section 01

Section 01

-

Section 04

Section 04

Section 04

Section 04

-

Wall to eaves detail

Wall to eaves detail

Wall to eaves detail

Wall to eaves detail

https://passivehouseplus.co.uk:8443/magazine/upgrade/from-derelict-shop-to-tiny-low-energy-home#sigProIdd632cd03a5