- Blogs

- Posted

New research raises spray foam health questions

New studies are seeking to answer questions about how spray foam insulation, and materials containing formaldehyde, affect indoor air quality —and some of the early results are worrying.

Preliminary research into emissions from cured spray polyurethane foam (SPF) insulation suggests that potentially harmful substances may continue to be emitted from the insulation long after it is installed. One study found that the flame retardant TCPP appeared to be off-gassing from spray foam two years after installation.

Speaking at an event held by the UK Indoor Environment Group (UKIEG) in May, UK scientist Dzhordzio Naldzhiev discussed both his own research at UCL, and research carried out by the US National Institute of Standards and Technology (NIST).

In lab tests at NIST, Dr Dustin Poppendeik and colleagues1 found a number of volatile organic compounds emitted from four different cured spray foam specimens: two relatively fresh samples (one open-cell, one closed-cell) supplied by an industry body, the American Chemistry Council, and two older specimens from real-life installations (again one open-cell, one closed-cell). Numerous compounds were detected – up to 80 in the case of one sample.

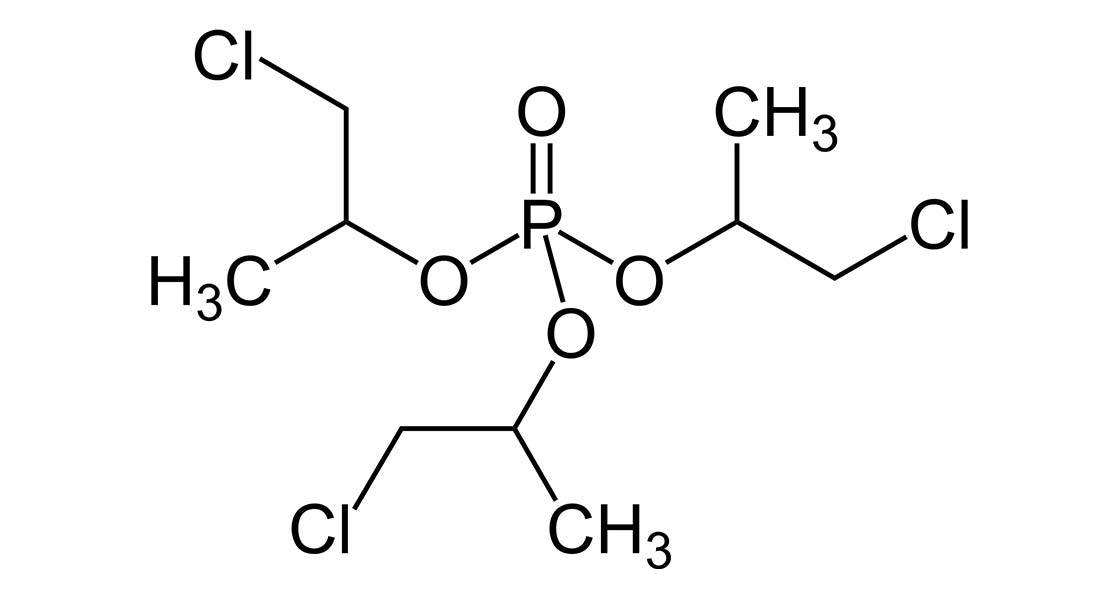

The concentration of most of the volatile compounds fell progressively in the test chambers over time, however for the two open cell samples, levels of the semi-volatile flame-retardant tris (1-chloro-2-propyl) phosphate (TCPP) remained steady. Similar results were also seen with one of the closed cell samples.

The authors suggest the unchanging emissions may have been because levels of flame retardant were high in the finished foam (the researchers cite reports that TCPP may comprise up to 12% of the mass of some spray foam formulations), meaning concentrations in the foam did not fall as the flame retardant “off-gassed”. They also note that emission rates varied by up to an order of magnitude for apparently similar products, meaning it was not possible to generalise conclusions from one foam to another.

This article was originally published in issue 28 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

Even though TCPP is a common ingredient in polyurethane foam products, there are no currently agreed exposure limits for the flame retardant2. However, as the NIST researchers point out, TCPP is classified by the EPA Design for the Environment Program as having “a high hazard for reproductive and developmental effects”.

The NIST researchers also measured levels of TCPP in the air of a test dwelling that had had the basement insulated with open-cell spray foam, two years previously. As the house was unfurnished, there were no other potential sources of flame retardant such as foam furniture to confuse the results.

According to the research, which was also discussed by Dzhordzio Naldzhiev at the UKIEG event4, TCPP was detected in the air in the ground floor of the house, and in the basement. As levels in the basement were approximately double those in the house, the researchers concluded that the spray foam there was almost certainly the source of the TCPP in the building.

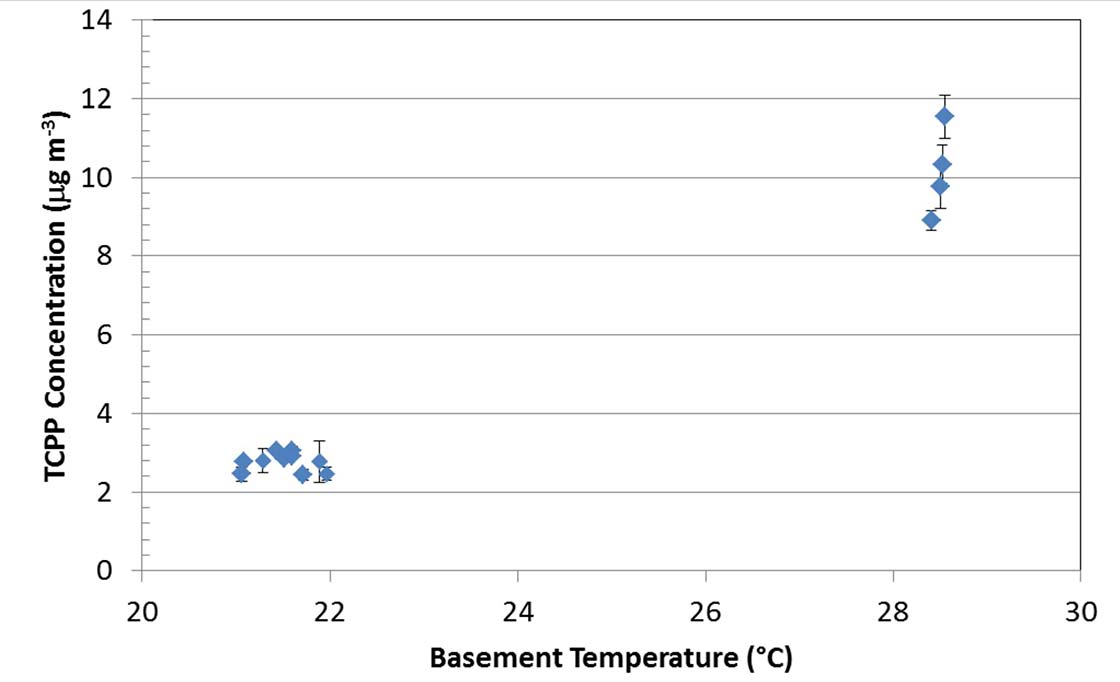

The team had found that in the lab, TCPP emissions from open cell foam rose exponentially with temperature. This effect was echoed in the test house (see graph). The temperature in the basement was raised from just above 21C to around 28C – the sort of rise that can be expected during heat waves. Repeat sampling showed levels of TCPP in the basement air rising from around 2-3 μg/m3 at 21C to 7-12 μg/m3 at 28C – at least a three-fold increase. These findings “suggest that occupants may be exposed to measurable concentrations of the flame retardant TCPP two years after application of open-cell foam,” the researchers wrote.

The US authors added the caveat that with only one real-life example tested, the research is still very limited, and it is not known how dependent emissions are on the particular product, or the way it was installed. Among the other compounds emitted from the spray foam specimens when they were fresh, Dustin Poppendieck and his colleagues at NIST detected 1,2 dichloropropane (1,2- DCP) and 1,4 dioxane. “1,4 dioxane is commonly detected emitting from closed-cell SPF [spray polyurethane foam],” the authors say.5 Canadian researchers have also reported that tests on spray foam specimens detected 1,4 dioxane.6

1,2- DCP and 1,4 dioxane are classified respectively as carcinogenic,7 and possibly carcinogenic. However, little is known about how they originate and whether they pose a health hazard in real-world applications, or even the best way to measure the chemicals. At UCL, Dzhordzhio Naldzhiev is starting the process of investigating emissions of 1,4 dioxane, 1,2- DCP, and other VOCs, from samples of different commercially available spray foam products, refining the measurement process so that a standardised method can be developed.

Naldzhiev told the UKIEG that, as part of as-yet unpublished research, he and his colleagues analysed three commercially available spray foam products to see if these two VOCs were present, and whether it was possible to work out where they originated.

The lab had detected 1,2- DCP being emitted from all three cured samples, and 1,4 dioxane only from one – but both compounds were found in the raw ingredients.

It has been suggested in the US literature that 1,4 dioxane and 1,2- DCP may be breakdown products of TCPP.8 Although they say they can’t be sure either way, Dzhordzhio Nadzhiev and his colleagues believe these VOCs might instead have found their way into the foam as constituents of raw SPF product, possibly as contaminants, so it might be possible to modify the manufacturing process to reduce or eliminate them.

Dr Naldzhiev’s team plan to investigate further, to establish the ‘real life’ levels of VOCs emitted by various spray foam products over one to two years or longer, and whether these are high enough to warrant concern. He added: “It is important to find the source and quantity of such emissions as it is a better strategy to eliminate them at the source, rather than mitigating them through ventilation strategies.”

He and his colleagues are concerned that use of SPFs is outstripping understanding of their possible impacts on the indoor environment.

In a research paper presented at an international ventilation conference in 2017,9 they wrote that “the potential long-term impact of these buildings materials and what ventilation strategies should be in place throughout the lifecycle of the building, in order to provide healthy IAQ, is still widely unknown.”

TCPP concentrations in the basement of a test house at different temperatures; the basement had previously been insulated with open-cell spray foam. From: Flame Retardant Emissions from Spray Polyurethane Foam Insulation D. Poppendieck, M. Schlegel, A. Connor, A. Blickley NIST

Persistent formaldehyde off-gassing

Another apparently persistent compound discussed at the UKIEG meeting last year was formaldehyde, which also appears to persist for a year or more after the completion of construction, and does not necessarily drop to safe levels before occupants move in.

Formaldehyde is a known irritant and suspected carcinogen, emitted by many engineered wood products and other construction and fit-out materials.

As part of as-yet unpublished research, Dr Clive Shrubsole and colleagues at UCL in London and Tsinghua University, Beijing, monitored a number of chemicals in indoor air in a range of buildings, including schools, offices and homes, in the UK and China.

Dr Shrubsole told the UKIEG: “We found formaldehyde levels of three times the recommended emission limit value in all the apartments we monitored, more than three years after the buildings were completed.”

This raises a question over the perceived wisdom that formaldehyde will have mainly off-gassed within a couple of years, Dr Shrubsole warned.

Dr Shrubsole’s findings were not an isolated instance. Tim Robinson of air testing company Waverton Analytics has also found elevated formaldehyde levels in a building post-occupation. He told a meeting of the Alliance for Sustainable Building Products in 201710 that he had recorded formaldehyde at ten times the WHO recommended limits in a school in Northwest England, one year after the building was occupied. Staff and students had complained of symptoms such as eye and throat irritation.

However, the UCL/Tsinghua study found “no notable” formaldehyde in a building which had been constructed to a low-emissivity specification. This suggests source control can be effective.

Spray foam installation

What installers & occupants need to know

There is long-standing concern about emissions during and immediately after insulation spraying, and what this means both for construction workers, and for occupants entering or re-entering a treated building. Isocyanates (“MDI”) are one of the main ingredients of spray foam – they comprise the “A” side in twocomponent foams. Isocyanates are an irritant and can cause a dangerous asthma-type reaction in people who become sensitised to them. Advice on the website of the US Environmental Protection Agency (EPA)11 warns of the following in relation to Isocyanates and other spray foam ingredients:

- Spray application generates isocyanate vapours and aerosols. Isocyanates can cause “sensitization,” which means that some people may become allergic to isocyanates and could experience allergic reactions including: itching and watery eyes, skin rashes, asthma, and other breathing difficulties. Symptoms may also be delayed up to several hours after exposure.

- If you are allergic or become sensitized, even low concentrations of isocyanates can trigger a severe asthma attack or other lung effects, or a potentially fatal reaction. There is no recognized safe level of exposure to isocyanates for sensitized individuals.

- Research data indicates that inhalation exposures during SPF insulation [installation] will typically exceed US Occupational Safety and Health Administration (OSHA) occupational exposure limits (OELs) and requires skin, eye and respiratory protection.

- Vapours and aerosols can migrate through the building if the area is not isolated and properly ventilated.

- After application, vapours may linger in a building until properly ventilated and thoroughly cleaned.

- Cutting or trimming the foam as it hardens (tack-free phase) may generate dust that may contain unreacted isocyanates and other chemicals.

- After application, dust may linger in a building until properly ventilated and thoroughly cleaned.

1 ‘Lessons Learned from Spray Polyurethane Foam Emission Testing using Micro-chambers’; Dustin Poppendieck, Mengyan Gong, Lauren Lawson, National Institute of Standards and Technology (https://ws680.nist.gov/publication/get_pdf.cfm?pub_id=921259)

2 (A Research paper published by the American Chemistry Council in 2014 says: “There is no Occupational Safety & Health Administration (OSHA) permissible exposure limit (PEL) nor American Conference of Industrial Hygienists (ACGIH) Threshold Limit Value (TLV) guideline for the flame retardant, Trichloropropyl phosphate (TCPP).”)

3 USEPA, ‘Flame Retardants Used in Flexible Polyurethane Foam: An Alternatives Assessment’. Update. In Environment, D. f. t., Ed. U.S. EPA: 2014 cited by Poppendeik et al ‘Flame Retardant Emissions from Spray Polyurethane Foam Insulation’.

4 ‘Flame Retardant Emissions from Spray Polyurethane Foam Insulation’; D. Poppendieck, M. Schlegel, A. Connor, A. Blickley, National Institute of Standards and Technology.

5 ‘Lessons Learned from Spray Polyurethane Foam Emission Testing using Micro-chamber’; Poppendeik & al.

6 NRC Publications Archive / Archives des publications du CNRC, ‘Material emissions testing: VOCs from wood, paint, and insulation materials’; Won, Doyun; Nong, Gang; Yang, Wenping; Collins, Peter (http://doi. org/10.4224/23002015).

7 https://monographs.iarc.fr/list-of-classifications-volumes/

8 Salthammer, T., Fuhrmann, F. & Uhde, E., 2003. ‘Flame retardants in the indoor environment—part II: release of VOCs (triethyl phosphate and halogenated degradation products) from polyurethane.’ Indoor Air, Volume 13, pp. 49-52.

9 https://www.aivc.org/news/aivc-conference-201710 https://asbp.org.uk/wp-content/uploads/2017/02/tim-Robinson-Waverton-ASBPExpo- 15-02-20171.pdf

11 https://www.epa.gov/saferchoice/potential-chemical-exposures-spray-polyurethane-foam