- Upgrade

- Posted

Certified passive nursing home extension breaks new ground

As Passive House Plus goes to press confirmation has come through that an extension to a nursing home in Celbridge, Co Kildare, has become the first healthcare building – and the first extension of any kind – to become certified passive.

When Garry and Norma Gavigan decided to extend Glenashling Nursing Home in Celbridge, sustainability was at the forefront of their thoughts.

Responding to a growing demand arising from Ireland’s aging population, the Gavigans saw the project as a chance to apply principles they’d picked up on their own self builds to the nursing home extension. Spurred on by the advice of Des Behan from Celbridge-based renewable energy specialists Masterheat, the Gavigans had invested in vertical borehole geothermal on one build, before building a highly insulated home with a heat pump with horizontal collectors and a solar thermal array.

The couple resolved to apply sustainable energy principles to the nursing home extension, with rising oil prices and the broader issues of sustainability playing on their minds.

According to Garry Gavigan, building to the passive house standard was part of an overall vision to deliver a high standard for individualised care that meets the needs of each resident.

“We didn’t just build this as a passive house for no reason,” he says. “The comfort and indoor air quality the passive approach brings is part of our commitment to taking care of our residents."

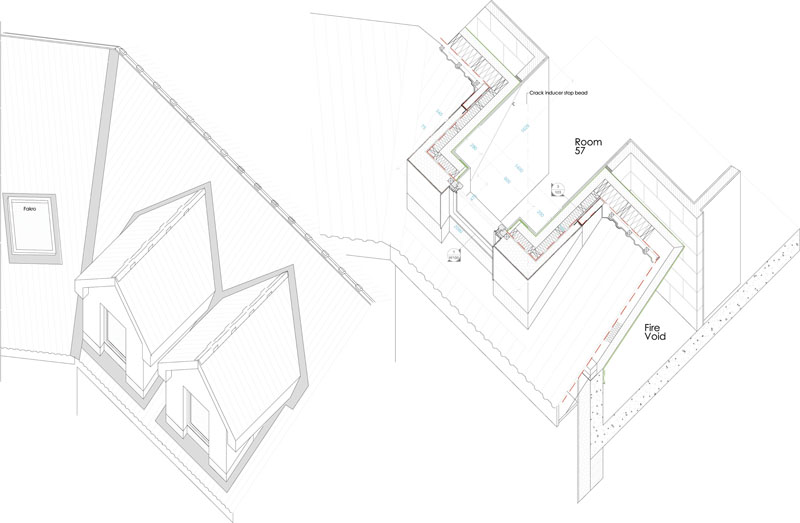

Careful detailing was required to prevent cold bridging and air leakage at the building’s many dormer windows

On top of Ireland’s international commitments to reduce environmental impacts, Gavigan was conscious that legislative requirements for health care buildings were changing while the project was being planned. The 2007 Health Act – given practical effect by The HIQA standards in 2009 – set requirements for the design and layout of healthcare buildings, with guidance set in terms of thermal comfort, ventilation and the overall quality of the care environment.

An approach that simultaneously ensures consistently comfortable temperatures along with controlled air change rates, passive house enabled Gavigan to exceed many of these requirements.

Like so many projects, this was a build bounded on all sides by constraints – budgetary, planning, regulatory – ever before it was decided to aim for passive. The fact that the project team managed to deliver a passive certified extension with limited extra budget and time, while the existing building continued in full operation – is testament to the quality of the people involved.

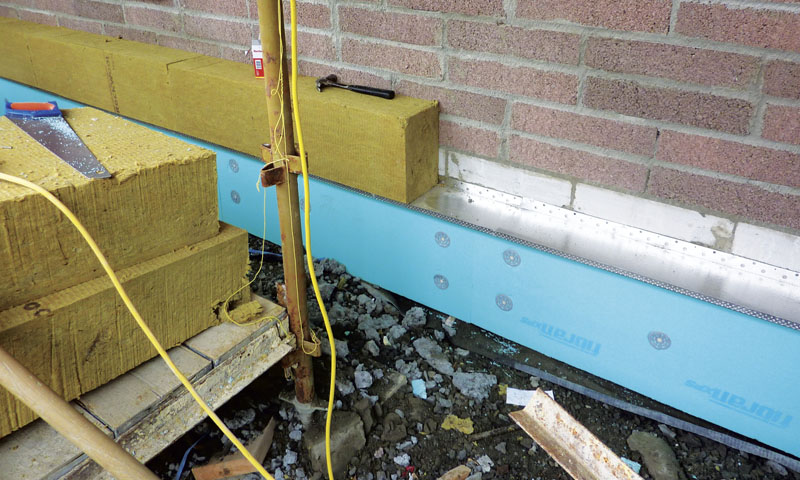

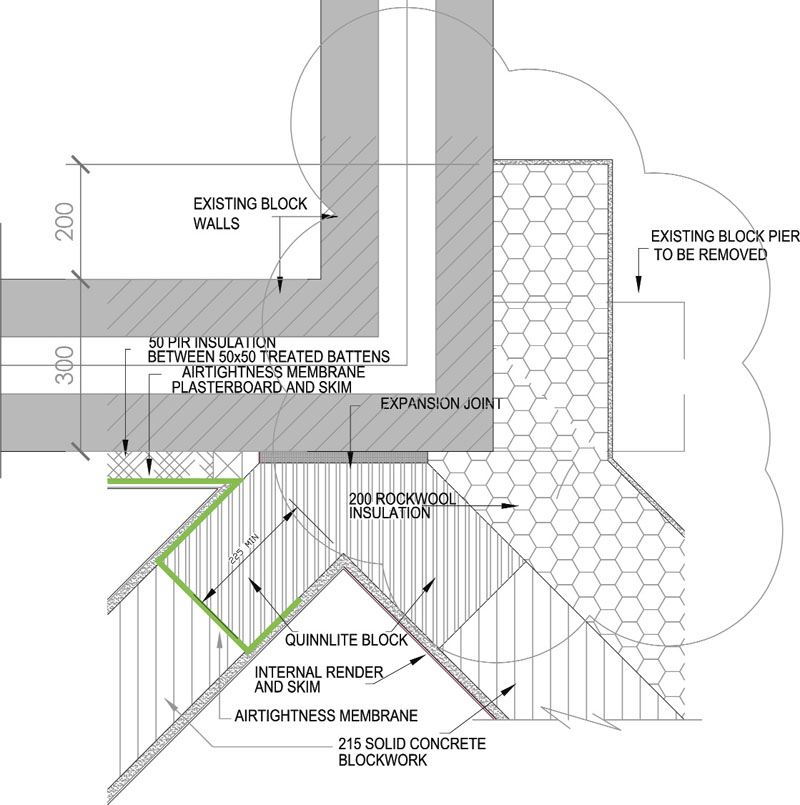

Details and thermal analysis of the new build connection to existing cavity wall with external insulation overlapping to prevent cold bridging

This is a 23 ensuite bedroom extension to an existing nursing home at Celbridge, Co Kildare. The new, two-storey structure is linked to the existing building – which also had an existing attic converted and energy upgraded, albeit not to passive levels – while a separate store, plant room and single apartment building were also constructed. In addition to the new bedrooms, a new kitchen, dining room, living spaces, sluice room, storage rooms and laundry room were built, along with site works and mechanical and electrical installations.

Gavigan emphasises that the aim was to build to passive levels from the outset, but was faced with constraints due to the existing building and the site layout. Mel O’Reilly of contractor MDY Construction acknowledges that these restrictions added challenge to the build.

“You’re now trying to incorporate airtightness details and insulation and everything else that goes with it into a structure that was not originally designed to accommodate them,” he says. MDY had however amassed considerable experience in low energy builds. Now, with the addition of Jay Stuart of DWEcoCo and Archie O’Donnell of Integrated Energy as passive house consultants, the team began working through the design to methodically work through the details and make sure passive house was achieved. “The whole team pulled together to deliver on the detail,” says Gavigan.

Windows are triple-glazed aluclad units from Harmon Vindeur

Gavigan also brought in Jim Clarke as project manager. “Under the watchful eye of Jim Clarke and MDY Construction, everyone worked together as a team,” says Gavigan. “It was so heartening to see the level of skill, knowledge and expertise that was applied by the different trades at all stages during construction.”

Archie O’Donnell of Integrated Energy says that his initial job was to work through the range of components and details needed to achieve passive house levels. “We came up with a specification, MDY Construction then priced it, and they were very quickly able to tell us if it was within budget. We had to make decisions on what combination of components would get us passive but would stay within budget.”

The agreed construction method – nine inch concrete block laid on the flat with 220mm of external insulation – not alone provided a highly buildable, on-budget structure, it also had the advantage of taking insulation off the critical time path. Airtightness in the new build was achieved with the combination of a wet plaster finish on internal walls, and Intello membranes and tapes in ceilings and at key junctions.

Thermal bridge free starter angle with closed cell EPS below

The devil however, was in the detailing, particularly when it came to interfacing the existing cavity wall structure with the new build. How was this managed? “With difficulty,” says O’Donnell. “In particular, MDY had to maintain fire access from the existing building, so they had to be very careful how they staged the process. Then we had to provide details for absolutely every junction within the building.” The high number of dormers also generated a lot of deskwork as details were worked though.

The combination of Quinn Lite blocks, low thermal conductivity wall ties and this endless succession of carefully engineered details did succeed in eliminating almost all of the thermal bridges in the build.

A meticulous approach on site ensured that the details to tackle cold bridging and airtightness made the transition from drawings to something more tangible: the finished building. “Looking at the work on the likes of the dormer windows,” says Gavigan, “the detail and the level of accuracy was absolutely amazing.”

Details of the new build connection to existing cavity wall with external insulation overlapping to prevent cold bridging

Both Jay Stuart and Archie O’Donnell note too that the fact that the main contractor was familiar with and understood the importance of airtightness was central in achieving such high results. Getting it right presented a range of challenges. In addition to marrying old and new structures, the commercial scale kitchen and laundry rooms meant there were far more penetrations than you would have to deal with in a residential project.

Brian Shannon of airtightness consultants Building Envelope Technologies visited the site at an early stage, pinpointed particular areas of concern and instructed the workers on site as the project went on. “We always get him out at an early stage,” says O’Reilly. “We find it valuable to have him as early as possible, engaging with the subcontractors and operatives on site.”

Particular problems arose in making the lift shaft airtight. Because of the number of fixings here, the design team originally planned to coat the shaft with an airtightness epoxy. It didn’t work. “That was quite a learning experience,” says O’Donnell. “There was no other way of doing it but by getting guys in there, getting a fan in place and just working to make sure that all the gaps are sealed.”

The airtight membrane was applied in sections, so that its continuity wasn’t disrupted by collar ties

Mel O’Reilly says that Gavigan’s resolve to build passive was a key factor in ensuring the building delivered its potential. “A lot of the time clients look at the bottom line and look at delays but on this project, the client was very keen to achieve the end result, and keen too to take on board advice from the consultants involved. That was a big plus.”

The current president of the Master Builders & Contractors Association – a constituent association of the Construction Industry Federation representing general contractors – O’Reilly believes the industry is ready for passive house. “The industry is gearing up and actively participating in the delivery of new technologies and wants to provide this type of building,” he says. “I know from talking to my colleagues around the table, we’re all determined to provide more energy efficient buildings. In particular we see a real need for the development of a retrofit programme for public and private buildings.”

According to O’Reilly, the experience that the industry stands to gain by building to passive house levels could be a decisive factor in creating an industry with the knowhow to deliver successful energy efficiency interventions across Ireland’s building stock. “If you take passive house as the pinnacle of low energy building, it becomes a yardstick against which you can measure the delivery of other energy efficient projects,” he says. “It changes the mind set and skill set. After you’ve achieved passive house, a high level of energy efficiency is much more achievable than before.” O’Reilly says that the knowledge picked up on the nursing home will be retained within MDY for future projects.

Jay Stuart points out the typical temperatures in nursing homes tend to be up around 24 degrees. “They need to be that high because most nursing homes have cold bridges everywhere and they’re not airtight. To compensate for the draughts you have to have a higher internal temperature and the heating bill is huge.”

These issues are completely neutralised in Celbridge. “You’ll have higher temperatures on all surfaces inside the building and people will just feel naturally more comfortable. And you won’t need a heating system because it’s a passive house,” he says.

With the extension’s passive house certification being confirmed just as Passive House Plus goes to print, Gavigan says Ireland’s first certified passive healthcare building is already proving a hit. “I’m delighted with the certification.” he says. “The response from the first residents who’ve moved in and from their families has been fantastic.”

Passive house consultant’s statement

By Jay Stuart, DWEcoCo

With planning consent for an extension to the nursing home nearing the end of its five year life, the client decided to build to the passive house standard. The design team he had at the time had no experience of passive house construction or low energy design and were struggling to get good advice. I was invited to join the team as the passive house consultant and proposed a simple, practical and cost-effective approach to going passive, including external insulation on blockwork. I was pleased when MDY Construction were selected as the contractor, as six years ago they very successfully built the Easton Mews low energy housing I had designed in nearby Leixlip.

The planning permission included some aspects that were less than optimal for passive house design, perhaps most notably in the form of many dormers, which are known to present cold bridging and airtightness problems. Potential problems like this can usually be overcome, with a little knowhow and application. In a sense the dormer detail was relatively painless, as it was a repeating detail. Once the first dormer was detailed for airtightness and thermal bridging, it was down to workmanship on site to achieve the standards.

The passive house standard isn’t just about the envelope – it also requires careful design of the services to keep the total primary energy use below 120 kilowatt hours per metre square per year. In this building we also needed to ensure the Health Information and Quality Authority standards were met.

The building won’t need much energy to keep warm. Some heat is recovered by the ventilation system, which incorporates small water to air heat exchangers in the supply duct in each room. There’s a thermostat in each room for individual control. As the ventilation system has heat recovery the supply air should be no less than 18C and this heating ‘battery’ can easily lift the air temperature up to 21C, the expected normal indoor temperature. It’s worth noting that 21C is a much lower temperature than is typically needed to achieve thermal comfort in Irish nursing homes – which like most of our buildings tend to be leaky and poorly insulated – because elderly people require higher temperatures to feel comfortable. But as thermal comfort is a combination of temperature, humidity, air movement and surface temperatures, it is possible to be comfortable at 21C in a building built to passive house standards because the other variables are already controlled.

I knew of the Blade heat server system by Zenex Technologies because they developed the GasSaver flue heat recovery system I had used in Easton Mews. This gas boiler system is most efficient when delivering hot water, which a nursing home needs in abundance. I proposed the system to the team and, after much research, it was installed. This is the first Blade in Ireland and its high efficiency performance will provide exemplary service and low running costs to the owner because of its innovative design and use of the flue heat recovery system.

The nursing home has a commercial washing machine and clothes dryer to cope with the laundry load of all its residents. I proposed heat recovery devices for both these appliances but the team didn’t implement these proposals. I know we could have made very cost-effective heat recovery devices for these appliances, which the owner says operate about eight hours a day. I estimate we would not have needed to install the Zenex Blade if we had heat recovery from these two appliances integrated with a buffer tank and a very small boiler. With more effort we could have developed a more cost-effective solution. Hopefully on the next project we can focus on the services from the beginning given that the envelope issues are relatively straightforward and easily achieved, with the right approach. This requires clients to employ good services engineers at an early stage of the project.

The next stage is for the owner to keep accurate records of how much energy is used in this extension. This data could be easily compared to the rest of his nursing home and if the calculations are done I would be surprised if there wasn’t a very strong business case for retrofitting the rest of his buildings to achieve similar savings and levels of comfort.

The HSE – which is paying for most of these bedrooms – should require the high indoor environmental standards that are achieved with the passive house approach, as they provide a much healthier environment for our older and more vulnerable citizens. In this situation the value of healthier indoor environments is far greater to the state than the energy saving is for the nursing home business. Fortunately there is no conflict in achieving both objectives.

Selected project details

Clients: Garry & Norma Gavigan

Project management: Clarke Partnership

Architect: Gavin Byrne

Architectural technician: Hugh O’Daly

Consultant structural & civil engineers: MTW Partnership

Consultant fire safety engineers: Ger Sexton & Partners

Consultant mechanical & electrical engineers: Malone Engineering

Passive house consultants: DWEcoCo

Passive house assessors: Integrated Energy

Passive house certifiers: MosArt Ltd

Building contractor: MDY Construction Ltd

Mechanical contractor: PJ Duffy

Electrical contractor: AJ Electrical

Quantity surveyors: Neil Lynch

Airtightness consultancy & testing: Building Envelope Technologies Ltd

Windows & doors: Harmon Vinduer Ltd

Roof lights: Fakro by Tradecraft

Airtightness products: Ecological Building Systems

Airtightness & roof insulation installation: Munster Insulation

External insulation: Durkan Ecofix

Additional insulation: Isover, Xtratherm & Kingspan

Thermal building blocks: Quinn Lite

Heat recovery ventilation installation: Ollie McPhillips Ltd

Heat recovery ventilation unit: Vent Axia

Boilers: Alpha Gas Saver