- Design Approaches

- Posted

Rest Assured

Nursing homes are typically amongst the most energy-hungry residential buildings, requiring higher room temperatures along with better air quality to maintain the health and comfort of often vulnerable inhabitants. But as energy prices rise, merely turning up the heating and turning on the air conditioning becomes a less and less viable solution. Brian Homan, Joint Managing Director of leading consulting engineers Homan O’Brien Associates describes a nursing home currently being built that is adopting a sustainable building approach to deliver healthy, comfortable accommodation at low running costs.

Kilternan Nursing Home presented us with a unique opportunity. The building is a near identical copy of a nursing home built in Rathmines eight years ago. The Rathmines Nursing Home, which has a floor area of approximately 2,000m², is heated by underfloor heating linked to gas fired condensing boiler plant. With the larger increase in gas prices in recent years the annual gas bill has risen from €5,000 per annum to €15,000 per annum.

The client, Cowper Care Ltd. were therefore very keen to investigate ways of reducing the new building’s heat loss and also look at more efficient means of generating heat for their new building.

BUILDING DESCRIPTION

As a nursing home, Kilternan Nursing Home is populated by over forty retired men and women together with a full time staff of over thirty people.

The building is a single storey masonry structure, has 47 beds and is composed of single and multi bedrooms provided with ensuite bathrooms together with dining facilities and administration. The building is extremely well insulated throughout. It is provided with heat recovery ventilation and is heated using a ground source heat pump.

Special low E glazing is provided with the U-value of the glass achieving 1.3 w/m2 K

BUILDING FABRIC

A number of studies were undertaken for a different wall construction, with a recent study confirming shortcomings in the performance of rigid board insulation. It was decided to use full fill cavity insulation. Initially the design team considered a glass wool blow fill insulation, however, it was decided to instead use polystyrene bead insulation. All wall cavities are provided with full fill cavity insulation. In addition to this, dry lining is provided internally using 50mm “Rockwool Flexi” mineral wool.

At roof level mineral fibre insulation between the joists together with insulation between the rafters has a combined thickness of over 350mm. The floor slab is insulated throughout with 100mm high density Aerobord. Special low E glazing is provided with the u-value of the glass achieving 1.3 w/m² K. Table 1 indicates the actual u-values achieved for Kilternan and compares them with u-values achieved for Rathmines.

HEAT RECOVERY VENTILATION

The building is provided with heat recovery ventilation (HRV) throughout. Ducted Air is supplied into each habitable room and extracted from all en-suite bathrooms and WCs which eliminates the requirement for wall vents. Heat from the warm extract air is added to the incoming fresh air via a plate heat exchange unit located in the attic. The quantity of air supplied equates to 1 air change per hour which would be similar to that achieved if wall vents were provided.

Heat recovery ventilation regulates and controls the fresh air supply to dwellings, a lack of which can lead to problems with condensation and damp. HRV filters air entering the dwelling which is useful in alleviating the symptoms of asthma, cold, hay-fever and other allergy sufferers by removing airborne pollution and irritants such as chemical gases that leech from building materials used in construction, paint, odours, dust, dust-mites and pet hair, a feature which is of benefit to older people, some of whom are not in the fullest of health.

As the heat exchange unit has an efficiency of over 50%, installing a system of this type reduces by over half the heat loss from air infiltration. With infiltration accounting for half of the overall building heat loss, a one quarter reduction in heat loss is therefore achieved using heat recovery ventilation. Figure 1 indicates the dramatic reduction in calculated heat losses from infiltration for Kilternan compared with the traditionally ventilated Rathmines Building.

Click either image for a larger view

GEOTHERMAL HEAT PUMP

The total building heat loss is approximately 60kw. To meet this load two 40kw geothermal heat pump units are provided. Twelve 170m deep bore holes where drilled adjacent to the building. 40mm diameter PVC pipework is looped through the boreholes and connected to the heat pump units in the plantroom. The heat pumps are in turn connected to the buildings underfloor heating system.

Duct work of the heat recovery ventilation system, which regulates and controls the fresh air supply, a lack of which can lead to problems with condensation and damp

The heat pump units extract heat from the ground by pumping water into the ground at 4ºC which then returns at 6ºC. The average temperature of the ground is typically between 8 and 10ºC. The refrigeration circuit in the heat pump then adds this heat to the underfloor heating system with a flow temperature of 30ºC and a return of 25ºC.

With these design temperatures the geothermal heat pump has a coefficient of performance of 6, which means that 6 units of heat are produced for each unit of electricity consumed. This statistic becomes even more attractive when the heat pumps run at night time using night rate electricity at a reduced tariff. Figure 2 indicates diagrammatically the heat pump arrangement together with the heat recovery ventilation.

Figure 2

Click image for larger view

A lot of research and consideration was given to whether the bore holes should be left with just the ground water surrounding the pipes or alternatively be back filled with pea gravel or bentonite. A number of different grades and qualities of bentonite are available. Using a full fill of some of the dearer bentonites could cost more than the drilling cost of the well which was around €5,000. We decided in the end to leave the ground water in the wells and cap the top 6 metres of the wells with bentonite.

Insulated pipwork and manifolds for the underfloor heating, which links to a bore hole ground source heat pump

HOT WATER

The Coefficient of Performance (COP) of a heat pump reduces as the temperature difference between the heat source and heat sink get larger. It is possible for a heat pump to generate water temperatures above 50ºC, however, the COP reduces to an uneconomic level. In Kilternan we have incorporated a preheat buffer vessel.

Hot water is pre heated in a buffer vessel from 10ºC to 30ºC using the heat pump as a heating medium. This water is then further heated to 55ºC by a gas fired water heater.

A trench, during construction, of the bore hole heat pump system. Hot water is pre heated in a buffer vessel from 10c to 30c using the heat pump as a heating medium. This water is then further heated to 55c by a gas fired water heater

COST ANALYSIS

The extra over cost of the geothermal system compared with a conventional gas fired boiler plant is in the region of €90,000.

The HRV system has an additional capital cost, however, it is worth noting that the extract ventilation side of the HRV system would have to be provided anyway as it is the extract ventilation system for the internal bathrooms, sluice rooms & WCs. Therefore the additional cost of the HRV units and supply ductwork is approximately €55,000. Table 2 indicates the energy consumption of Rathmines compared with the predicted energy consumption for Kilternan.

Carrying out a simple payback exercise the payback would be just over 11 years. Gas prices rose 30% last year and will rise by a similar amount this year. If we conservatively estimate that gas and electricity costs will rise by 10% per annum next year and in subsequent years, the payback period reduces to just over 7 years. I believe we are at the beginning of a steep rise in fossil fuel costs. Energy efficient buildings in the future will sell for a premium which is a factor not taken into account in these payback calculations.

Client: Cowper Care Ltd.

Architect: Ryan O’Brien Handy

Mechanical & Electrical Consulting Engineers: Homan O’Brien Associates

- Articles

- Design Approaches

- Rest Assured

- Homan

- Nursing Home

- building fabric

- heat recovery

- Ventilation

- kilternan

- geothermal heat pump

- underfloor heating

Related items

-

In defense of fabric

-

Why airtightness, moisture and ventilation matter for passive house

Why airtightness, moisture and ventilation matter for passive house -

ProAir pioneers with EPDs for ventilation systems

ProAir pioneers with EPDs for ventilation systems -

Let’s bring ventilation in from the cold

Let’s bring ventilation in from the cold -

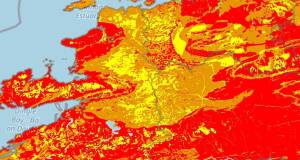

45,000 more Irish homes face radon risk, new maps reveal

45,000 more Irish homes face radon risk, new maps reveal -

ProAir retooling for the future

ProAir retooling for the future -

Ecological launch Inventer decentralised ventilation

Ecological launch Inventer decentralised ventilation -

Poor ventilation a Covid risk in 40 per cent of classrooms, study finds

Poor ventilation a Covid risk in 40 per cent of classrooms, study finds -

Efficient ventilation key to healthier indoor spaces – Partel

Efficient ventilation key to healthier indoor spaces – Partel -

Evidence emerges of endemic ventilation regs breaches

Evidence emerges of endemic ventilation regs breaches -

Window-opening unreliable for ventilation, study finds

Window-opening unreliable for ventilation, study finds -

Study confirms “systematic inequalities” in indoor air pollution

Study confirms “systematic inequalities” in indoor air pollution