International

Since she started an MSc in Advanced Environmental and Energy Studies at the Centre of Alternative Technology in Wales, architect Minka McInerney’s practice has embraced an ecological approach to building, specialising in retrofit design, consensus design and sustainability consultancy. McInerney is a member of both the Building Regulation Advisory Board and the RIAI's sustainability task force. She is currently writing her thesis, a comparative study of building materials and embodied energy in passive house design. Here, she profiles six deep green buildings that take unique approaches to sustainability, across matters ranging from aesthetics, design and procurement to materials, thermal comfort and energy use.

>

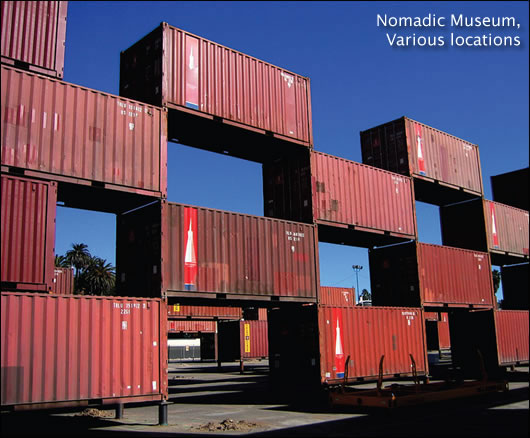

This is a truly international example, a building that visited New York in 2005, Santa Monica in 2006, Tokyo in 2007 and Mexico City in 2008. The Nomadic Museum houses the Ashes and Snow exhibition of 200 large scale artworks by Canadian photographer Gregory Colbert. Colbert has travelled extensively to remote locations to capture the interactions between animals and humans. The photographer wanted a permanent traveling exhibition with an emphasis on sustainability that could be assembled and dismantled easily in various cities around the world. The dramatically lit photographs hanging from cables were to be exhibited in a ‘mystical’ space without any natural daylight, to create an appropriate poetic context.

The first genesis of the Nomadic Museum was Pier 54 in New York in 2005, designed by Japanese architect Shigeru Ban and Buro Happold engineers. The materials are mainly renewable or recyclable, consisting of 148 empty shipping containers stacked 10.4m high forming a self-supporting frame, with a 760mm diameter waterproof paper tubing forming the columns and trusses, with a fabric ceiling. The main central pathway was made from reclaimed scaffolding planks and is framed by river stones, and the space is divided by a handmade curtain made from pressed Sri Lankan paper tea bags.

The envelope is comprised of 148 empty containers that form a self-supporting frame over 10m high

The contents of the exhibition were packed into 37 of the shipping containers for the journey to Santa Monica. The building was free to evolve from place to place to suit changing circumstances. When it reached Santa Monica the pier structure was shorter and wider than in New York, and the original 61m long gallery was divided into two parallel galleries without increasing the number of containers. The museum evolved further when it reached Mexico City, where Colombian architect Simon Velez replaced the original cardboard structure with the largest bamboo structure ever built.

Hawaii Preparatory Academy (HPA) is located in an idyllic setting at the foot of the Kohala Mountains on the Big Island and enjoys a very mild climate, sunny weather and a gentle breeze. HPA is an independent coeducational school founded in 1949 that caters for students from kindergarten through to secondary school. In 2006 students examined the school’s energy consumption and the potential for renewable energy, and made recommendations that led to the formation of their Go Green movement, pushing environmental issues firmly to the top of the school's agenda. The design concepts came about during subsequent Go Green workshops. Aside from an exemplary ecological building, the school wanted to create a special learning environment that would encourage collaboration and experimentation. The intention was that the laboratory could be used by students of all ages and levels, from young children to PhD scholars.

Wood sun screens —along with polycarbonate skylights and and interior roller shades — all work together to introduce, reflect, and control natural daylight

The laboratory building design — overseen by Flansburgh Architects — is based on traditional Hawaiian house typology with a main hall, collaborative spaces, indoor and outdoor classrooms, and workshop. The building was designed to fulfil the Living Building Challenge, the comprehensive performance based benchmark for truly sustainable buildings developed by the Cascadia chapter of the US Green Building Council. The Living Building Challenge is met by satisfying sixteen conditions related to the site, energy, materials, water and indoor quality, as well as a building’s aesthetic and ability to inspire. It is awarded based on actual monitored — rather than modelled — performance.

Energy use in the building is net negative — it only consumes between 20-30% of the energy generated from its 27kW of photovoltaic panels and wind turbines. The remainder of the energy is exported to the main school campus. All potable water is generated through rainwater harvesting and filtration. Fifteen thousand litres of water is captured for every 25mm of rain falling on the 560m2 roof.

Large areas of the roof ccommodate solar PV

The building is naturally ventilated though a traditional Hawaiian tropical three-pitch roof design with shading to the south. A natural convection draught occurs as the mountainside wind blowing over the roof draws cooler air into the building. There is also a radiant cooling system comprising an insulated water tank storing chilled water. At night water is circulated through thermal roof panels, cooled via lower evening temperatures, then stored in the tank for use as chilled water for air handling units during warm afternoons.

The choice of materials was guided by avoiding certain toxins such as formaldehyde, mercury and lead, and limits were placed on the distance from the site building materials could travel, with an emphasis on regional resources such a lava rock. Most waste generated during construction was recycled — for example woodchip was used in landscaping.

The building is extensively monitored and centrally controlled in terms of energy input and output, cooling, heating, ventilation and carbon dioxide levels for use as a learning tool.

The Tebogo Home for Handicapped Children is located in the Orange Farm township about 45km southwest of Johannesburg. Orange Farm is a difficult place to live, enduring widespread poverty, illiteracy, unemployment and Aids. Local corrugated sheet buildings have no temperature modification properties, resulting in blistering indoor temperatures over 45C in the summer dropping to a freezing 2C on winter nights.

This project was initiated in 2004 by the Austrian NGO Sarch (Social Sustainable Architecture), which strives to provide community facilities in developing countries. The existing home had become too small, and new spaces to house dining/kitchen and therapy facilities were required. BASEhabitat project studio both designed and was involved hands-on in building the project. BASEhabitat is part of the School of Architecture, Kunstuniversitat, Linz and specialises in architecture for developing countries. In this project the team was made up of 25 students working with professional supervisors. The building layouts are very simple, comprising separate dining/kitchen and therapy buildings connected to an existing building via an external pergola.

A variety of rich colour is achieved in wattle and daub due to the use of different local soils

BASEhabitat tends to apply three goals to their projects. First, passive house design tempers the local climate. The sun provides any heating requirement and the thermal mass of the fabric of the building provides cooling. Thus the cool structure of the Tebogo building slowly absorbs solar heat gains during the day, and then releases the heat back into the building when the internal temperature starts to cool at night. There is no additional energy input required and the internal temperature fluctuation has been reduced to 9C throughout the year.

The second goal is to utilise local, unprocessed materials. At Tebogo these include earth, soil, clay, air-dried concrete bricks, hay, wood and grass mats — all sourced from Orange Farm. Renowned Austrian earth builder Martin Rauch consulted on the project. The main walls are wattle and daub construction — wattle, or timber wooded slats laid horizontally are filled with daub, a combination of wet soil, straw and binding additives. In one building the wattle is left exposed and there is a variety of colour due to the different local soils used. The rich colours and textures of the selected materials are striking, and give the building a strong sense of identity that is quite literally related to its location.

(above left) part of the new dining and kitchen facility; (top) 25 students with supervisors designed and built the project; (above) an external pergola connects the two buildings

The third consideration is to ensure the design and implementation contributes positively to the local community, in that the design and technology can be used by the community to develop future prototypes and the construction carried out by local people. This project also provided the Austrian students involved with firsthand ecological building experience, with a cultural twist.

Westborough School in Essex, England is attended by 750 pupils aged between three and 11. The Department of Environment commissioned this project — designed by Cottrell & Vermuelen Architecture — as part of their mandate to encourage more sustainable construction methods. Buro Happold was assigned structural engineer given the firm's extensive experience in the field of cardboard construction (though this is their first permanent cardboard structure). The brief was to design and construct an after school club with ancillary store, kitchen and WCs using 90% recycled materials with a minimum 20 year life span that would be 90% recyclable upon deconstruction.

The single storey pavilion building, measuring 15m long x 6m wide, is light, airy and elegant, and set in an enclosed garden decorated with graphics representing origami herons, drawn by the artist Simon Patterson to represent this local bird species. Materials were locally sourced in an unconventional way by encouraging staff, students and parents to recycle their paper and cardboard in large containers throughout the school. The card was then distributed to three different manufacturing facilities to make various building elements. The internal finishes also include a recycled rubber floor.

Cardboard columns support a central timber truss, and there are cardboard panels cladding both the walls and roofs. The main structure consists of two rows of 11 cardboard tubes made of 15mm thick card, measuring 183mm in diameter. In areas requiring additional support a series of columns are grouped together, as at the end of the timber truss. The wall and roof infill panels have an interesting concertina shape reminiscent of origami paper folding, suiting the material and improving the load bearing capacity of the columns. The infill panels are made up of an inner and outer layer of 6mm solid cardboard, with three further layers of 50mm honeycombed cardboard sandwiched between 2mm solid cardboard.

Apart from making the structure work, the other main challenges were water ingress and fire. Water penetration was dealt with in various ways, including the use of water resistant cardboard, an internal polymer vapour barrier, external breather membrane and external wood fibre & cement panel product.

Surface spread of flame rather than structural integrity was the main risk with fire. An additional treatment layer to reduce surface spread of flame was applied to exposed ceilings. The thick card building elements perform similarly to timber — while the outer edge will char, the structural integrity will be conserved long enough to evacuate the building. As part of a live BBC Tomorrow's World program, the properties of fire protection were dramatically tested on prototype building elements by flame throwers, followed by a hosing down by a fire engine.

The striking grey and white patterned facade, recording the light and shadows that fell on the once vacant site of this new nine storey apartment building located in central London, belies the massive timber structure that makes Stadthaus the tallest modern timber residential building in the world. The previously established limit of timber frame construction is seven storeys. The scheme accommodates ground floor retail units and 29 apartments. The building was commissioned by Telford Homes Ltd with normal speculative considerations rather than any ecological agenda. Waugh Thistleton Architects presented various structural solutions which led to the selection of a timber rather than steel structure for reasons of program and cost. The timber structure was erected in eight weeks.

Massive timber construction is fundamentally different from timber frame because the loads are distributed over greater area, increasing the structural capacity. Apart from the reinforced concrete ground floor construction, the floors, internal and external walls, stair and lift cores and roof are all constructed from prefabricated cross laminate timber (CLT). CLT specialists KLH developed this structural system and fabricated the CLT in Austria. The CLT consists of low grade spruce boards industrially dried, then stacked together at right angles and glued together at high pressure to reduce the natural expansion and shrinkage of timber to a negligible level. A formaldehyde free isocyanate adhesive was used to mitigate toxicity.

The external walls consist of 128mm cross laminate timber (CLT) with 100 mm insulation applied externally

The external walls consist of 128mm CLT with 100mm insulation applied externally. Eternit panels measuring 1.2m x 230mm and made from 70% waste timber clad the building externally, protecting the CLT from moisture. Internally, the walls are finished with plasterboard. The walls achieve a very low U-value of 0.13W/m2K. Massive timber has a relatively low thermal conductivity when compared to other standard building materials such as brick or concrete, and the continuous nature of the construction reduces thermal bridging. The floor slab is made up of 146mm CLT with acoustic insulation above and below and 55mm screed forming the floor surface.

All opes for windows and doors and service penetrations were formed at the fabrication stage. Very low tolerances were achieved (+/-5mm) contributing to a high level of airtightness. The impact of the material selection was calculated by the designers, in terms of both embodied and sequestered carbon. There is a saving of some 124 tonnes of embodied C02 in comparison to standard reinforced concrete construction and the timber fabric sequesters an estimated 188 tonnes of carbon. These savings were offset against the need to provide renewable energy, which can be challenging in built up areas. The apartments are fitted with heat recovery ventilation that recovers about 70% of heat, as well as a small photovoltaic array on the roof that powers both the lights in common areas, and some pumps.

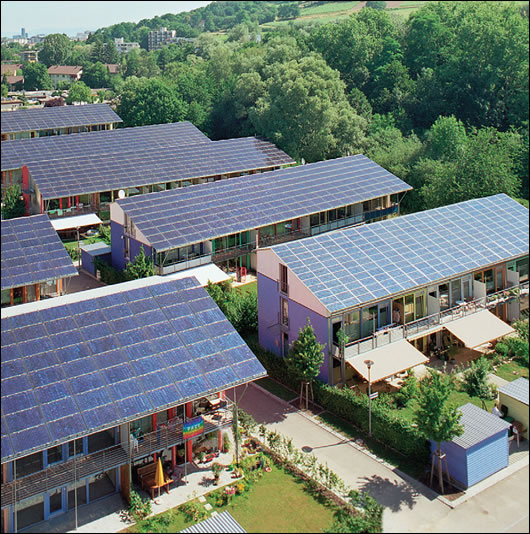

The Solar Siedlung (Solar Settlement) in Freiburg, Germany is a mixed-use development designed on the basis that it would produce more energy than it consumes. Freiburg has been an environmentally conscious town since the 1970s and has been awarded various environmental awards, including 'Sustainable City' in 2004. During the 1990s the city authorities recognised the economic importance of solar energy and environmental policies. Freiburg enjoys excellent solar access with approximately 1800 hours of sunshine per year (compared to 1400 – 1700 in Ireland). In 2002 the Renewable Energy Sources Act (EEG) became law in Germany — this legislates that grid operators must pay to buy electricity generated from renewable energy sources. Within this framework Solarsiedlung SmbH, together with local architect Rolph Disch, developed the energy plus Solar Settlement. The German Energy Plus or Plusenergie standard, developed by Disch, is for buildings that generate more energy through active and passive solar strategies than they consume over their lifetime. The project was financed by a number of ethical-ecological investment funds which earn returns on 15 of the completed residential units.

The wider development includes 52 homes with solar PV-clad roofing

The Solar Settlement includes the Sonnenschiff (Sun Ship) building, housing the EcoInstitute and containing a 1200m2 eco-supermarket and other retail outlets, some 3,600m2 of offices and clinics, and nine penthouse apartments. The remainder of the settlement includes 52 homes located in the site beyond. The active energy is generated from the grid connected 445kW total peak output PV system on a galvanised steel support structure fixed onto the south facing roofs. The roofs have large overhangs to provide summer shading.

The Sonnenschiff service centre is designed to screen the remainder of the community from traffic and provide sustainable service facilities to the wider community. It is a reinforced concrete structure with a specially designed timber post-and-beam facade, with triple-glazed windows and vacuum insulated panels. Both ventilation and heat recovery are incorporated into the facade. The multicolour palette was devised by German artist Erich Wiesner.

The Sun Ship service centre is designed to shield the residential areas from traffic; roofs have large overhangs to provide summer shading

The residential element of the solar settlement has average total energy consumption per house of 2,200 kWh/yr. The houses have very low U-values with 0.12 W/m2K exterior walls and 0.7 W/m2K triple-glazed windows, and are fitted with heat recovery ventilation units

- Articles

- International green buildings

- Cardboard building

- Recycled Museum

- Unusual

- Unique Sustainable Projects

- Tallest Timber Building

Related items

-

Big picture - Points of access to resilient living

Big picture - Points of access to resilient living -

Emma Stone show puts passive house up in lights

Emma Stone show puts passive house up in lights -

Big picture - Huff'n'Puff Haus - a straw bale passive house

Big picture - Huff'n'Puff Haus - a straw bale passive house -

Big picture - off grid passive house in British Columbia

Big picture - off grid passive house in British Columbia -

International - Issue 39

International - Issue 39 -

International - Issue 38

International - Issue 38 -

International - Issue 36

International - Issue 36 -

International - Issue 35

International - Issue 35 -

International - Issue 34

International - Issue 34 -

International - Issue 33

International - Issue 33 -

International: Issue 30

International: Issue 30 -

International: Issue 31

International: Issue 31