- Product News

- Posted

Framespace steel-frame system passes thermal imaging test

This article was originally published in issue 20 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

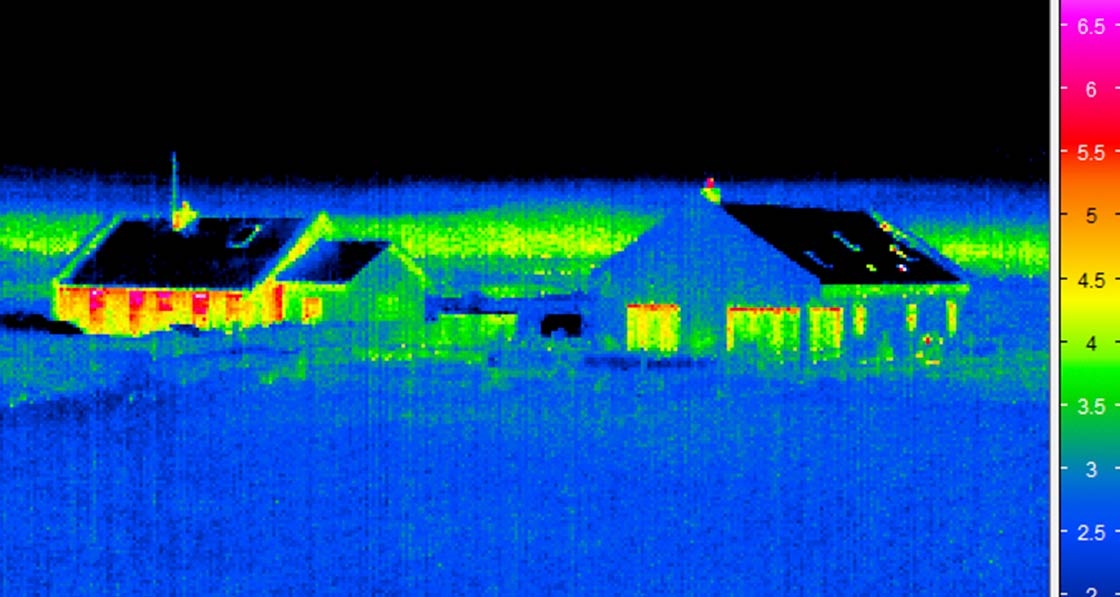

The prefabricated, externally insulated steelframe house (seen in the images to the left), built by Cork-based Framespace, achieved an A1 building energy rating, and was completed in November 2016. Meanwhile the house in the bottom image is of conventional cavity wall construction, and dates from 2005.

The survey took place at 6.30am on February 24 this year. Both houses had their heating set at 20C beforehand for a period of approximately 12 hours, to ensure conditions were similar, and to allow heat to escape from both dwellings.

Comparing the two images clearly shows significant heat loss (indicated by red and orange) from the front façade of the cavity wall house. The external walls of the Framespace house, by comparison, are the same colour as the surrounding grass — meaning that little heat is escaping. The cavity wall house also has an extension with external insulation at its right gable, which also shows good heat retention.

“Comparing the two houses, the benefits of external insulation on the Framespace system becomes immediately apparent,” Christ Spoorenberg of EcoScan wrote in his thermal imaging report.

“The lower overall-surface temperature (approx 2-3C) is an indication for substantially less heat loss. Perhaps less evident but also present are the benefits on detailing. The cold-bridging, such as around window reveals and wall-plates in the conventional setup, are effectively addressed where external insulation is applied.”

The report continues: “But more so, cavitywall insulation comes with the inevitable gaps making it less effective. This is caused by: heatconducting wall ties, dirty boards, damaged boards, unfinished corners, un-tight fitted boards, inaccurate cuttings and other introduced defects… These defects are inherent to cavitywall insulation and lead to easy transfer of heat through the fitted insulation and subsequently convection of heated air inside the cavity. With thermal imaging this leaves ‘patchy’ surface temperature patterns.”

For more information on Framespace, see www.framespace.ie.

Related items

-

EPDs key to reducing embodied carbon – Munster Joinery

EPDs key to reducing embodied carbon – Munster Joinery -

Ecomerchant now stocking Herschel Infrared heating products

Ecomerchant now stocking Herschel Infrared heating products -

Mannok named one of Ireland’s best managed companies

Mannok named one of Ireland’s best managed companies -

Aluclad windows offer numerous advantages: Prestige Aluclad

Aluclad windows offer numerous advantages: Prestige Aluclad -

Window-opening unreliable for ventilation, study finds

Window-opening unreliable for ventilation, study finds -

Prodomo offer certified thermal brackets for windows and doors

Prodomo offer certified thermal brackets for windows and doors