News

September’s AECB environmental construction conference seeks to spark debate among industry experts

Industry leaders will gather at University of East Anglia in September to share practical insights on creating buildings that prioritise environmental performance without compromising design quality or occupant comfort.

Climate report warns overheating crisis threatens UK

A newly published landmark study has said thirteen UK areas face severe climate risks as schools brace for ten-week heatwaves.

Sustainable building leaders crowned at Exemplar Awards

The winners of the inaugural Exemplar Sustainable Buildings Awards were announced in London on 25 June, celebrating the Sustainable Development Foundation's 20th anniversary.

Barratt launches record passive house scheme

Leading developer Barratt London has announced plans for its ‘Lo-E’ Homes programme, which will deliver sustainable new homes at scale across the British capital and exceed passive house standards.

Green homes and finance join forces for growth

Certified green homes are becoming mainstream across Europe – boosted by collaboration from experts in green building and finance. Smarter Finance for EU (Smarter4EU), a pan-European initiative dedicated to the creation of a mainstream European green housing market, announced a range of new initiatives at the “Banking on Green Homes" event in Madrid, on 28 May.

Irish and British associations unite for conference as passive house explodes

The 2025 UK and Ireland Passivhaus Conference, themed Climate Emergency: The Passivhaus Solution, is set to bring together hundreds of sustainable building professionals in Belfast this October.

Enniscorthy to host ‘make or break’ sustainable building summit

As global temperatures soar, an Irish organisation is bringing experts together this month for a summit on the future of sustainable construction.

Banks turn to green housing courses as EU sustainability rules bite

Help is at hand for European financial institutions scrambling to train staff in sustainable housing finance as regulatory pressure intensifies and customer demand for green mortgages accelerates across the continent.

Ecocem executive John Reddy becomes the first Irish President of the Institute of Concrete Technology

Reddy is the first person from Ireland to hold the role of President of ICT, which has a term of two years, and follows his term of Vice President of the organisation since 2023.

POLL: UK public detached from net zero goals

A survey of 1,500 UK homeowners by the Social Market Foundation (SMF) – a cross-party think tank – has revealed government failure to make people feel confident in taking steps for the net zero transition, jeopardising its success.

Wales unveils net zero pattern book

Wales’s devolved government has moved forward with plans to standardise sustainable, timber-based affordable homes in the country with the publication of a new pattern book.

Scotland to accept passive house as regs compliant

Certified passive house to be alternative means of compliance to proposed Scottish passive house equivalent.

Green homes key to climate and housing crises and rebuilding Ukraine

The Smarter Finance for EU consortium, which is aiming to unlock €100bn worth of green homes across Europe, announced the launch of a European centre of excellence to promote green home certification and investment across Europe at the Irish Green Building Council’s annual residential conference in Dublin.

Plain English book tells story of embodied carbon

Canadian green building writer and architect Lloyd Alter has published a book to explain the importance of embodied carbon in simple terms.

70 per cent grants for passive house training

There may never be a better time for companies to upskill their staff in passive house, Enerphit and net zero construction – thanks to new 70 per cent grants.

Pilot UK net zero carbon buildings standard launched

A pilot version of the UK’s first cross-industry standard for net zero carbon-aligned buildings has been launched.

Green homes a “multi-trillion euros opportunity” – but greenwashing must end

Europe’s burgeoning green homes market is a multi-trillion euros opportunity – but lenders must be wary of facilitating greenwashing, a pan-European consortium has warned.

Study: gas cooking killing 40,000 Europeans per year

Gas cooking is killing 40,000 European people a year in Europe, a major new study has revealed, with an average of almost two years taken off their life in the EU and United Kingdom due to exposure to nitrogen dioxide (NO2) emitted during gas cooking.The countries with the highest burden were Italy, Poland, Romania, France and the UK.

£30m passive scheme launched in Down

Multi-award winning Belfast-based property developer, Fraser Millar, has launched Northern Ireland’s second large-scale residential passive house development – a 74-unit scheme of detached and semi-detached homes at a total project value of £30m.

Unilin appoints new general manager for the UK and Ireland

Aidan Doyle has joined insulation manufacturer, Unilin Insulation, as General Manager for both the Ireland and UK businesses.

High performance buildings essential for climate and quality of life

The en masse global shift to high performance buildings is essential to meeting the climate challenge and improving quality of life around the world, an international conference has heard.

St Albans passive house scheme launches, promising luxury and energy income

Home buyers seeking sustainable luxury and energy income in a sought-after part of England have a rare opportunity with a newly launched passive house scheme in St Albans.

Scotland committed to continuing passive house journey

Patrick Harvie MSP, the Scottish government’s minister for zero carbon buildings, active travel and tenants' rights, was a keynote speaker at the UK Passivhaus Conference in Edinburgh on 17 October, and shared his vision for energy efficient and low carbon buildings in Scotland.

AECB conference 2023: from edible landscaping to whole life carbon

Delegates at the 2023 AECB Conference heard a wide range of speakers covering everything from guerrilla edible planting to peak oil to detailed discussions on whole life carbon calculation.

Building or upgrading?

If you’re pricing, designing or constructing a building – whether it's an energy upgrade of a small house or a sustainable new build home, office or multi unit scheme – Passive House Plus can help.

Click here to get in contact with the companies you need, and receive a copy of Passive House Plus for free!

Marketplace

Ecological Building Systems expands UK and Irish straw panel construction with EcoCocon deal

EcoCocon, a leading European manufacturer of prefabricated straw wall panels, has announced a new, exclusive partnership with Ecological Building Systems, making EcoCocon's innovative straw-based wall system more accessible to professionals across the UK and Irish construction markets.

21-08-2025 Marketplace

Focus on better buildings, not better spreadsheets

Does the sustainable building industry prioritise spreadsheets over real-world performance? And what is the upshot of this? These are the questions Will Kirkman, managing director of Ecomerchant is putting to the sector.

30-07-2025 Marketplace

MBC offers total passive house envelope solutions

MBC Timber Frame, a well-established leader in passive house construction, now offers a comprehensive envelope solution for passive house projects.

30-07-2025 Marketplace

Historic Dublin building retrofitted with cutting edge insulation

A landmark Georgian building on St Stephen’s Green has become the latest showcase for innovative sustainable building technology, as the Office of Public Works completes a major retrofit using Firetite aerated clay cavity wall insulation, supplied by Econ Building Products.

30-07-2025 Marketplace

Proctor gains ground with Scottish passive schools

A. Proctor Group’s Wraptite airtightness membrane is being specified in a number of Scottish passive schools – including an award-winning school in Perth and Kinross.Riverside Primary, Scotland’s inaugural primary school…

Full EPD Certification for Pro Clima airtightness and windtightness products

Pioneering airtightness and windtightness solutions manufacturer Pro Clima has secured environmental product declaration (EPD) certification for its range of membranes, tapes, and glues—one of the most extensive assessments of its kind.

Ecocem venture may speed up EU cement decarbonisation by a decade

Green cement pioneer Ecocem has announced the construction of its first production facility dedicated to ACT, its low carbon, globally scalable cement technology, at its Dunkirk site.

Ecomerchant founder announces new green podcast

A new podcast dedicated to longform interviews with leaders in the natural building sector will be launched this year.

We Build Eco sees growth in people wanting to build eco the easy way

Interest in flat pack bio-based building is growing, according to We Build Eco, which creates easy to assemble, energy efficient building kits manufactured from any design.

Insulated foundation system greenlit by BBA

Kore Insulation has received the stamp of approval for the Kore Insulated Foundation System from the UK’s construction product certification body, the British Board of Agrément (BBA).

Passive EcoWall from Ecological Building systems cuts whole life carbon

The construction industry can drive down embodied carbon emissions while achieving best practice energy performance - using a tried and tested solution from one of the UK’s pioneering green building…

Grant launches new generation “game-changer” heat pump

Leading heating technology manufacturer Grant has announced the launch of its next generation air source heat pump – the Grant Aerona 290, which is now available to order.

Lung disease patient: Zehnder MVHR “the best thing I’ve ever had”

A Scottish lung disease patient has credited a Zehnder heat recovery ventilation system with causing such a significant improvement in his respiratory health that he’s been taken off a lung transplant list.

Proctor creates head of global sales for modular offsite sector

A. Proctor Group has announced the promotion of Adam Salt to the position of head of global sales modular offsite, effective immediately.

Why airtightness, moisture and ventilation matter for passive house

Ecological Building Systems technical specification advisor Dave Judd looks at airtightness, active moisture control and effective ventilation in passive house properties.

Ireland’s first 3D printed homes insulated with clay foam

Ireland’s first 3D printed housing project has been delivered in Dundalk – integrating Firetite aerated clay cavity wall insulation.

Sisk-led consortium secures £500,000 fund from Innovate UK

Sisk, in collaboration with a consortium of leading low carbon industry experts, has announced that it has been successful in securing £500,000 from Innovate UK funding as part of the…

Ecocem appoints new UK and Ireland MD

Ecocem, Europe’s leading provider of low carbon cement technologies, has today announced the appointment of Sally Anne Sherry as managing director for its UK and Ireland business operations. In this…

New tool to ease certification of smaller passive schemes

Passive house certification for smaller scale projects just got substantially simpler – thanks to a new software tool launched by the Passive House Institute.

MgO boards to disrupt construction industry, report claims

Magnesium oxide (MgO) boards are poised to “disrupt” the construction industry, a new white paper has claimed – meaning products like Cem-Rock from Limerickbased supplier Greenspan may be poised for widespread adoption.

- 1

- 2

- 3

- 4

From the magazine

Blogs

Energy poverty and electric heating

As electricity decarbonises, the case for switching from fossil fuel boilers to efficient use of electricity to heat buildings via heat pumps has become overwhelming. But in markets like the UK where electricity is far more expensive than the European average, and people on low incomes may be chronically underheating poorly insulated homes, could a drive to electrify heating exacerbate energy poverty?

Three books and a taxi ride

Peter Rickaby looks back on an extraordinary career, the challenge of convincing people of the need for a new approach to buildings, and the people who helped him to do just that.

The transformative power of industrialised retrofit

The retrofit market is messy, scuppered by knowledge and skills gaps, and inconsistent approaches. Ele George makes the case for industrialisation to level up the retrofit market.

Tripling EU / UK Energy Efficiency Policy: the NZEB

One of Europe’s key climate breakthroughs came in the form of the EU’s nearly zero energy building target, as Dr. Marc Ó Riain explains in the latest part of his series on the history of low energy building.

Passive house doesn't care about materials

One stubborn trope in some corners of green building is that passive house is so focused on energy performance that its advocates ignoring materials. Not so, argues Toby Cambray.

We need to talk about women and retrofit

Our efforts to retrofit homes across the UK and Ireland will be severely hampered unless we engage meaningfully with and empower women homeowners and professionals, writes Ellora Coupe, founder of Her Retrofit Space.

If passive house is Everest, we’ve left base camp

The construction industry is moving in great numbers towards the passive house standard. In an adapted version of a speech at the Construction Industry Federation Conference in September, Passive House Association of Ireland chair Caroline Ashe Brady looks at the trek ahead.

In defense of fabric

As the grid gets greener and the case for heat pumps as a decarbonisation silver bullet becomes increasingly compelling, questions are starting to be asked about how far we need to go with retrofitting building fabric – or whether we need improve fabric at all. We ignore fabric at our peril, warns Toby Cambray.

Out of the blue - a passive revolution

Near the peak of the Celtic Tiger – at a time when developers were throwing up often sub-standard homes at a record pace, one self-build project pointed to a different approach, writes Dr Marc Ó Riain.

Buy, hold or sell

Recent analysis has suggested a slowdown in the property sector for 2024, but what impact might a drop in inflation have? Mel Reynolds runs the numbers.

An early green building in a changing Ireland

It’s fair to say that green building wasn’t a thing in early 90s Ireland, which makes one extraordinary Dublin project from 1994 all the more remarkable, as Dr. Marc O Riain writes.

Bedding sustainability into British buildings: Bioregional’s BedZed

Shortlisted for the Stirling Prize in 2003, BedZed was a prominent example of architecture starting to pay attention to sustainability. But how well did it work? In the latest part of his series on the history of low energy architecture, Dr. Marc O Riain looks back at a landmark project.

The PH+ guides

The PH+ guide to thermal breaks

Building physics take no prisoners. Anyone designing, constructing or upgrading the thermal envelope of a building to modern energy performance levels is duty bound to understand and minimise thermal bridging, or suffer the consequences. One-man thermal bridging encyclopaedia Andrew Lundberg of Passivate, who teaches thermal bridging analysis at Dublin Institute of Technology, gives some practical advice on why and how to tackle thermal bridging head on, and describes some of the leading innovations in thermally broken components.

19-04-2018 Guides

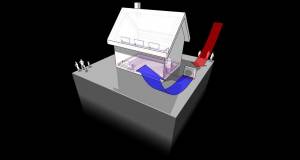

The PH+ guide to air source heat pumps

As electricity supply from renewable sources continues to grow, and electricity grids gradually decarbonise as dirtier fossil fuels are phased out, heating homes with electrical technologies like heat pumps starts to make more sense. And in the mild, temperate climate of Britain and Ireland, air source heat pumps are particularly suitable — especially as new build standards of energy efficiency continue to tighten, meaning new homes need less and less energy to achieve comfortable indoor temperatures. But how do air source heat pumps work, what types are there, and how much do they cost to run? Our in-depth guide attempts...

08-05-2018 Guides

Timber frame & mass timber: the Passive House Plus guide to structural timber construction

Fuelled by the need to build quickly and to increasingly tight sustainability standards, the market for timber frame and mass timber construction is growing rapidly. This detailed guide covers many of the main established and emerging techniques, and looks at key issues to address if you’re considering a timber-based build.

05-07-2019 Guides

The PH+ guide to airtightness

Once poorly understood by the mainstream building industry, airtightness is now increasingly seen as one of the most crucial objectives on any building project. Not only is it vital for energy efficiency, it’s also key for thermal comfort and for protecting a building’s structure from dampness and mould. In this comprehensive guide to airtightness, we look at why it’s so important, how exactly it’s measured, and most importantly, how to achieve it on site.

04-02-2019 Guides