- New build

- Posted

Storm breaker

Five years ago, a fabric first trailblazer took a dose of his own medicine – and delivered a family home that combines climate action, comfort, cost-effectiveness and resilience in the face of a record-breaking storm.

Click here for project specs and suppliers

Development type: 260 m2 detached home

Method: Timber frame, natural insulation, insulated foundations, heat pump and PV

Location: Co. Cavan

Standard: Passive house classic

Energy bills: €187 per month for all energy use – including circa 48,000 km/year worth of EV charging and including VAT and standing charges.

In January Storm Éowyn’s record breaking 183 km/h winds wreaked a trail of destruction throughout Ireland, with nearly 800,000 homes, farms and businesses losing power. In the aftermath any homes without open fires, stoves or ranges were left without heating. The Crosson family’s home in rural County Cavan was no exception, the power cut lasting for six days. With subzero temperatures at night, and peaks of 5 to 6C during the day, how did the house fare without a heating system?

“The temperature in all the main living spaces never dropped below 20C,” says Niall Crosson. “I took a photo of the thermostat on the day the power came back on and that was 20.4C at 11:10PM. My brother in law came in and was fascinated it was still warm. We were playing Monopoly with the kids under candlelight and he said ‘I know what it is – you’re heating the house with candles.’”

Some of Crosson’s neighbours in homes built more recently, to Ireland’s nearly zero energy building (NZEB) standard evidently didn’t cope as well without heat, opting to move out till power was restored. “It just shows the resilience of passive house compared to NZEB,” he says.

If anyone is deserving of such a startling demonstration of the virtues of rigorous, fabric first approaches to construction it’s Niall Crosson. Over the last two decades the construction industry in the UK and Ireland has gradually accepted the critical role of airtightness in delivering energy savings in building. If you could pin down responsibility for that transition to any one person above all – not to mention his work on breathability and the role of natural materials – it would be Crosson.

This article was originally published in issue 49 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

As the long-serving technical director of Ecological Building Systems in Athboy, Co. Meath, it was only a matter of time before Crosson and his growing family would seek to make their own transition from a Celtic Tiger timber frame home in Bailieborough town to an ambitious self-build passive house, incorporating the proven tricks of a trade focused on high performance natural building materials that he and his firm have helped the industry apply so expertly on sites all across the UK and Ireland.

So, it goes without saying that the expectations for this project were high, not just for Crosson himself but for his colleagues, suppliers, customers and, of course, his family. But in fairness to him, Crosson very much embraced these expectations, as we’ll see later.

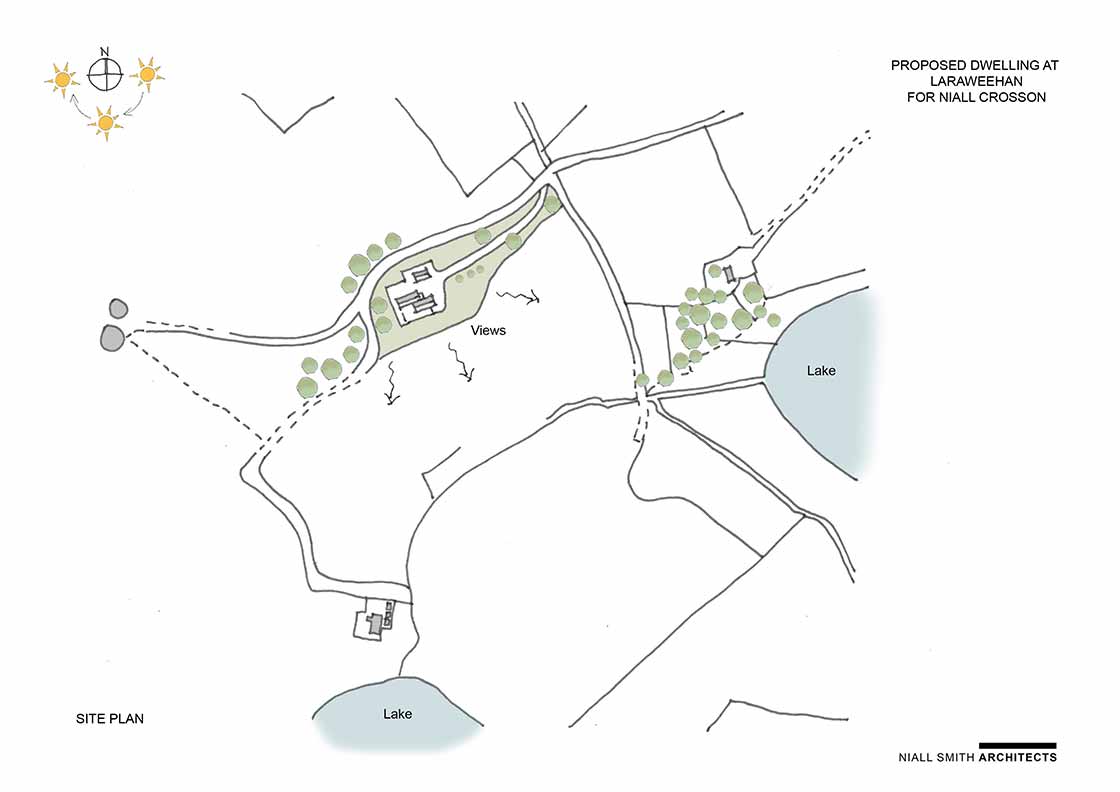

As his starting point, Crosson was fortunate to have the option, along with his other siblings, to choose a site from his father’s large family farm if they ever wanted to build there. The farm, located in the townland of Laraweehan, near Cootehill, Co. Cavan, is deep in the heart of a very distinct and wellknown topography of rolling hills and small lakes often termed ‘drumlins’, an area that has been likened to a basket of eggs.

When the time came, Crosson chose a field where he had strong memories of growing up doing the silage and other typical jobs that fell to members of a large farming family. It was also shaped in a way that required little in the way of land cutting and levelling and had nice views to the south and of two small lakes, the larger of which supply the local, community- managed water scheme.

Adhering closely to the council’s vernacular rules meant clipped eaves, short overhangs, no large soffits and a tipped verge on the gable sides.

As you would expect, Crosson has an extensive address book of expert designers, consultants and tradespeople he could call upon, but one consistent guiding factor in choosing his project team was the distance they were based to his locality, not to mention supporting local employment.

“What I found was I did have a lot of contacts, which I was really blessed and lucky to have built up over many years and who I could trust ... but you have to be a realist and think about who is in the locality and who you can access at very short notice when things go wrong or you need some adjustment on site,” said Crosson.

Even with the best preparation in the world, “when something needs to be adjusted quickly and you need to call someone, it's very important to have someone as local as possible not just for local employment, but also for practical reasons when sometimes you just need someone very quickly”.

This principle extended to everyone from kitchen supplier Liam McDermott who lives a stone’s throw from the house, to Crosson’s choice of architect, Niall Smith, who at the time was in the process of building his own, RIAI-award winning house in nearby Kingscourt. Crosson was regularly on his site advising Smith on condensation risk analysis for his roof and airtightness guidance when he tapped him to work on Laraweehan.

“It was natural to reach out to Niall because we're of similar age and he appreciates contemporary design, but also the local vernacular architecture we have around this part of the country as well,” said Crosson.

Informed by his passive house expertise, Crosson himself wanted a design that was simple in form, with a single roof and either a square or possibly an L shape.

“The design of the house is inspired by the site itself with the two lakes and the rolling drumlins of Cavan,” said Smith. “The concept is three vernacular blocks with the garage to the north and the entrance from the northeast and we have a two-storey block that forms the entrance to the building and a single-storey to the south where all the living spaces are to maximise the light from the east in the morning to the south and to the views of the lakes, and then the evening sun in the west.”

While Smith was careful to utilise materials from the locality, his contemporary ideas were still quite far away from what the couple had initially visualised, but also rubbed up somewhat uncomfortably against Crosson’s instinct for simple forms and keeping the outer envelope area to a minimum, mainly because it involved stretching the main building across two blocks.

Add to this Carol’s insistence that they add a room above the kitchen in the small, single- storey block that, in turn, required creating a link to the adjoining second-storey building for practical purposes and therefore more potential for thermal bridges and airtightness issues.

“I just wanted to keep it simple, minimise the risk of any leakages, but I had to cater for what turned out to be a practical addition that's really valuable now today and was well worth the effort,” said Crosson. He adds that today one of his maxims is that where complexity arises, but it is something you need, you have to embrace it. “She was 100 per cent right, and I still remind her to this day.”

If you're getting up at 4AM for a flight to go away for work, you go into the bathroom, you come out and it's just consistently warm.

The advantage of stretching the main across two blocks was they could put all the living on the south side of the building and the toilets, showers and wet rooms to the north side, and also take account of the second lake rather than just one.

There remained a good bit of back and forth before they all settled on the final design, which neatly combines contemporary design with elements of 19th and early 20th century Cavan and Monaghan farmhouse styles. “I think that's the value of having a professional architect involved because they just see things and appreciate things in a very different way,” said Crosson.

Adhering as closely as possible to the county council’s vernacular rules also meant clipped eaves, short overhangs and no large soffits and a tipped verge on the gable sides. All this meant the strategy for shading had to focus on the creation of canopies, a small one at the front entrance and a bigger one over the south-facing outdoor living spaces looking out onto the lakes.

Site excavation work

-

Site excavation work, with less digging required than for a conventional foundation system

Site excavation work, with less digging required than for a conventional foundation system

Site excavation work, with less digging required than for a conventional foundation system

Site excavation work, with less digging required than for a conventional foundation system

-

The KORE insulated foundation system sits on compacted hardcore;

The KORE insulated foundation system sits on compacted hardcore;

The KORE insulated foundation system sits on compacted hardcore;

The KORE insulated foundation system sits on compacted hardcore;

-

A construction detail showing the continuous thermal layer from foundation to external wall

A construction detail showing the continuous thermal layer from foundation to external wall

A construction detail showing the continuous thermal layer from foundation to external wall

A construction detail showing the continuous thermal layer from foundation to external wall

-

Warm feet, sparingly used underfloor heating and the placebo effect of a fake fire

Warm feet, sparingly used underfloor heating and the placebo effect of a fake fire

Warm feet, sparingly used underfloor heating and the placebo effect of a fake fire

Warm feet, sparingly used underfloor heating and the placebo effect of a fake fire

https://passivehouseplus.co.uk/magazine/new-build/storm-breaker#sigProId09ee2a13bb

Crosson is quietly proud of how they more than met the requirements of the county council in respect of how well the house fits into the landscape as well as being sympathetic to the local vernacular. Proof of that came some two years after the completion of his build when his brother, who had started building his own house on another farm site, came up against some challenges with planning. The local authority sent him a guidance on what they would foresee as the ideal positioning of the house and how it fits into the area. “They gave him a planning number and he looked it up online, and to my surprise it was my house that they were using as a reference.”

Crosson very much took charge of the build process, filling the roles of contractor, project manager and energy consultant as well as sourcing the materials provided by Ecological Building Systems.

With the help of his brother-in-law, Paul Boylan, he fitted the slates on the roof and also rolled up his sleeves on some of the airtightness and the insulation work – even pulling in some of his kids to help with the latter task.

Niall’s long-term work colleague and friend Roman Szypura of Clíoma House carried out all the primary airtightness and insulation work along with his skilful colleague Gary. Roman installed Gutex Thermofibre blown woodfibre throughout the house to all external walls, roofs and attic areas. While cellulose could have alternatively been used, Crosson really liked the idea of combining a wood insulation with minimal processing, with a timber-based building. It was also a family affair with a cousin doing bricklaying duty and his brother-in-law Paul also helping with the first and second fix carpentry.

In terms of suppliers for the core timber frame structure, Crosson had the pick of some of the top names and trusted partners in this sector, including Emmet Nee of Long Life Structures in Galway, Donal Mullins of Shoalwater Timber Frame in Wexford and Neil Orr of Building Kudos in Belfast. While any of these firms would have undoubtedly gone above and beyond for this valued client, sticking faithfully to his preference for local suppliers made Crosson’s choice of Timbertech Homes in neighbouring Co. Meath a bit easier.

While a timber frame construction was the natural choice, there was a little bit of a learning curve with the decision to use Ecological’s nascent Passive Eco Wall concept.

True to Crosson’s enthusiasm for minimising complexity, this concept enables builders to adapt varying thicknesses of the Gutex woodfibre exterior insulation or the stud depth to achieve a specific U-value depending on either your budget or design requirements (or both). It’s also designed so that a vapour membrane is not necessary, thereby minimising the number of layers involved and therefore the complexity, says Crosson.

“So, you've got wood fibre outside, a stud infilled with natural fibre insulation and then you've got a board inside that's airtight, an internal racking board that’s vapour resistant as well to give you vapour controlling properties.”

One of his many initial engagements with Fergal O’Malley at Timbertech was going through in detail all the junctions and the ways to minimise thermal bridging, and limit the use of steel as much as possible in the fabric by replacing it with cement board on the first floor instead of a block exterior.

Walls gallery

-

The layers of Ecological Building Systems' Passive EcoWall system, which was used on the house

The layers of Ecological Building Systems' Passive EcoWall system, which was used on the house

The layers of Ecological Building Systems' Passive EcoWall system, which was used on the house

The layers of Ecological Building Systems' Passive EcoWall system, which was used on the house

-

An airtight strip of Solitex Plus, with properties including an integrated reinforcing mesh which help to retain the continuity of the airtight layer at the wall to floor junction

An airtight strip of Solitex Plus, with properties including an integrated reinforcing mesh which help to retain the continuity of the airtight layer at the wall to floor junction

An airtight strip of Solitex Plus, with properties including an integrated reinforcing mesh which help to retain the continuity of the airtight layer at the wall to floor junction

An airtight strip of Solitex Plus, with properties including an integrated reinforcing mesh which help to retain the continuity of the airtight layer at the wall to floor junction

-

Factory built panels from Timbertech at first floor level

Factory built panels from Timbertech at first floor level

Factory built panels from Timbertech at first floor level

Factory built panels from Timbertech at first floor level

-

Fronta membrane to ventilated cavity and blockwork

Fronta membrane to ventilated cavity and blockwork

Fronta membrane to ventilated cavity and blockwork

Fronta membrane to ventilated cavity and blockwork

https://passivehouseplus.co.uk/magazine/new-build/storm-breaker#sigProIdd5edc4278e

Some of the large corner triple glazed windows, supplied by Rationel, presented a thermal bridging challenge in places where a concrete lintel is required to support their weighty frames, but the solutions here were simple and effective. Above the passive raft foundation, the sliding doors and floor-to-ceiling windows are sitting on insulation blocks made of recycled polyurethane called Bosig Phonotherm that is strong enough to support the weight of the frames and eliminate another potentially big thermal bridge. This was covered and sealed with Pro Clima Extoseal Encors butyl flashing tape to provide the desired weather-tightness, particularly given the exposure of the site to the southwest prevailing winds.

In terms of other key suppliers, Crosson chose Fermanagh-based Patrick Fallis (Fallis Passive) for the cladding, zinc and canopies; and Castleblayney firm NRG Panel, who supplied both the heat pump and general plumbing. He also employed Paul Halpin, of Halpin Electric who worked closed with NRG Panel in the past. He was particularly keen to use a plumber and electrician who had worked together before because of the “massive crossover” between such elements as the air-to-water heat pump, plumbing and general electrics within the house.

Being spread across two blocks rather than a single entity, a bit more thought had to go into ensuring that the Brink heat recovery ventilation system was able to service both blocks of the building. A solution involving separate systems for each block was considered but ruled out on the grounds of cost and complexity.

The job of installing the MVHR ducting, however, was one that underlined just how service penetrations for pipes and cables are among the weakest links in a building’s airtightness envelope. “Regrettably some airtightness membrane was accidently damaged by a subcontractor at this stage,” says Crosson, “but thankfully it was immediately identified and repaired. This illustrates the importance of diligence and quality control on site”.

Roof gallery

-

80 mm Gutex Multitherm woodfibre board

80 mm Gutex Multitherm woodfibre board

80 mm Gutex Multitherm woodfibre board

80 mm Gutex Multitherm woodfibre board

-

Solitex Plus Connect breathable roofing underlay with integrated wind-tightness tape to seal laps

Solitex Plus Connect breathable roofing underlay with integrated wind-tightness tape to seal laps

Solitex Plus Connect breathable roofing underlay with integrated wind-tightness tape to seal laps

Solitex Plus Connect breathable roofing underlay with integrated wind-tightness tape to seal laps

-

44 x 44 mm battens/counter battens.

44 x 44 mm battens/counter battens.

44 x 44 mm battens/counter battens.

44 x 44 mm battens/counter battens.

https://passivehouseplus.co.uk/magazine/new-build/storm-breaker#sigProIde214745494

The ground had been broken in May 2018, with the Crossons moving in 18 months later in November 2019. A closer look at the pictures taken during the build phase shows what look like quite a few site visits from clients, contractors and suppliers. You can well imagine Crosson relishing the prospect of putting his own money where he has put his mouth for several years as technical director for Ecological and make the most of the opportunity to showcase their finest products on a site over which he has one hundred per cent control.

“When I started with Ecological [Building Systems], I was the first employee, but I was coming in as a qualified engineer and one thing I realised from the get-go was training and education,” he said. “This is absolutely key to everything this company is going to have to do to bring the market forward. So, when it came to the house, it was just natural for me to think I've done this with so many other projects where people are building. I have to do it with our house.”

Throughout the build process Laraweehan served as a location for open days, events, conferences and several training workshops on topics relating to the application of various woodfibre insulation and airtightness products and attended by installers from across Ireland, the UK and Germany.

Crosson also had the bright idea to commission a YouTube video blog series that detailed various phases of the build, which is available to view on the Ecological Building Systems website. While not quite of the standard of videos they are producing in 2025, he’s happy that it helped him to embrace the high expectations of Laraweehan and to share its finer technical details with Ecological’s entire eco-system.

Airtightness gallery

-

Vapourblock panels taped together to form the airtight layer

Vapourblock panels taped together to form the airtight layer

Vapourblock panels taped together to form the airtight layer

Vapourblock panels taped together to form the airtight layer

-

75 mm service void insulated with Thermafleece Cosywool insulation

75 mm service void insulated with Thermafleece Cosywool insulation

75 mm service void insulated with Thermafleece Cosywool insulation

75 mm service void insulated with Thermafleece Cosywool insulation

-

Airtight taping around a Fakro roof window

Airtight taping around a Fakro roof window

Airtight taping around a Fakro roof window

Airtight taping around a Fakro roof window

-

75 mm of Thermafleece Cosywool insulation, in a service void between the airtight membrane and MVHR ductwork

75 mm of Thermafleece Cosywool insulation, in a service void between the airtight membrane and MVHR ductwork

75 mm of Thermafleece Cosywool insulation, in a service void between the airtight membrane and MVHR ductwork

75 mm of Thermafleece Cosywool insulation, in a service void between the airtight membrane and MVHR ductwork

-

One of many open days at the house during its construction.

One of many open days at the house during its construction.

One of many open days at the house during its construction.

One of many open days at the house during its construction.

https://passivehouseplus.co.uk/magazine/new-build/storm-breaker#sigProIdbedd511f46

“It’s just great to be able to look back [at] “now and then” pictures because you forget about a lot of the people that came and the work you did in that area … it was a good opportunity also for the suppliers to come in, like Rationel [windows], the plumber, the architect, the timber frame or the ventilation guy Chris Miller; all them people got an opportunity to speak before the plasterboard went on.”

While he’s happy with the energy performance, airtightness, space demand and heat load requirements of Laraweehan, the house is certified passive house classic but that was without any solar PV panels – a decision made at the time purely for rolling budget and timing reasons. He has since had them installed by Ecoplex Energy Solutions and plans to ask his certifier what difference it could have made to meeting the passive house plus standard. “They’ve already made a huge difference to running costs because I have EV and charger at home, and I do quite a high mileage.”

Other future plans include fitting a brise soleil solar shading on the west of the house, where rooms at that end can overheat to 28- 29˚C during the summer. He is also considering retrofitting some kind of rainwater harvesting system.

Long after the building was completed, Crosson commissioned Wain Morehead Architects to conduct some embodied carbon calculations, using the PHribbon tool to repurpose the PHPP calculations required for passive house certification to work out most of the material quantities. The building fared exceptionally well, achieving a cradleto- grave score of 366 kg CO2e/m2, comfortably beating the target of 450 kg CO2e/m2 for dwellings of more than 133 m2 in the 2030 RIAI Climate Challenge, in spite of some likely over-conservative assumptions in the calculations which increased the materials total by up to 15 per cent (see panel below for more).

As a measure of how fast things are progressing in terms of the work of lowering embodied carbon emissions, Crosson says he would have probably used cement board or timber cladding throughout, instead of blockwork for the outer leaf of the house, and GGBS for the concrete screed – two of the measures he shared during a talk at the ZEB Summit conference in February 2024 at the RDS.

Very fortuitously, the Crosson family moved into Laraweehan just before the Covid 19 lockdowns kicked in, and the difference in terms of comfort, consistency of temperature and ventilation were felt almost immediately.

“I vividly remember one of the first times having a shower and getting out of the shower and not being freezing in the house,” he said. “So especially early in the morning, if you're getting up for a flight to go away for work or something, you go into the bathroom, you come out and it's just consistently warm.” There have been tangible health benefits, too. Two of his three children are mildly asthmatic, but they have not had to use their inhalers once since moving in, which is likely down to improved indoor air quality resultant form the combination of heat recovery ventilation and the suite of natural materials used throughout the house, he says.

Thermal bridging and insulation gallery

-

Roman Szypura of Clíoma House pumping in cellulose insulation

Roman Szypura of Clíoma House pumping in cellulose insulation

Roman Szypura of Clíoma House pumping in cellulose insulation

Roman Szypura of Clíoma House pumping in cellulose insulation

-

A section of airtight membrane removed shows the cellulose blown in at such a high density it stays intact

A section of airtight membrane removed shows the cellulose blown in at such a high density it stays intact

A section of airtight membrane removed shows the cellulose blown in at such a high density it stays intact

A section of airtight membrane removed shows the cellulose blown in at such a high density it stays intact

-

120 mm of Gutex Multitherm wood fibre board externally wraps the timber frame structure

120 mm of Gutex Multitherm wood fibre board externally wraps the timber frame structure

120 mm of Gutex Multitherm wood fibre board externally wraps the timber frame structure

120 mm of Gutex Multitherm wood fibre board externally wraps the timber frame structure

-

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

-

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

Bosig Phonotherm thermal break at threshold and a window reveal beneath a structural steel beam

https://passivehouseplus.co.uk/magazine/new-build/storm-breaker#sigProId0ee7955b31

Whole life carbon

As Passive House Plus is published in UK and Ireland editions, the building was assessed against the RIAI 2030 Climate Challenge and, the new UK Net Zero Carbon Building Standard (NZCBS), which assesses how buildings are aligned with the UK’s net zero targets by 2050.

In line with the EU’s Level(s) framework, the RIAI targets set cradle-to-grave targets and set a 50 year reference study period (or assumed lifespan). At present the NZCBS includes targets for upfront carbon only, therefore not considering any emissions assumed to be released when components are replaced during the home’s life, or at the building’s eventual end of life. One important clarification when looking at upfront carbon only: this new standard does not count the sequestered CO2 in upfront targets, meaning it’s not possible to engage in the kinds of accountancy tricks to make bio-based materials appear to be net carbon negative.

The calculation has conservatism built into it too, which were applied both in the case of RIAI and NZCBS targets. As per the new standard, 15 per cent is added to the material totals as a default for cases where the Environmental Product Declarations have not been identified for the actual materials used. However, in this case, EPDs have been identified for most materials used – notably including the KORE EPS insulation, Rationel windows, PV array and Gutex wood fibre insulation.

2030 is currently in pilot phase, and the results were impressive. The building scored an upfront total of 283 kg CO2e/m2 GIA, surpassing the standard’s 2030 target for family homes, ignoring the fact that the total may drop by circa 10 per cent if the EPDs for materials were considered. It is worth noting that the NZCBS does not include emissions from the PV array. As per the LETI approach to embodied carbon, roof-mounted PV is considered as part of the electricity grid, whereas building-integrated PV arrays – which form part of the enclosure for the building – are counted. However, in the case of the RIAI and RIBA voluntary climate targets, roof-mounted PV is included. Given the relatively low embodied carbon of the Leapton panels specified, the net impact is much small than some previous cases published in these pages. The panels only add 8 kg CO2e/m2 to the upfront total, or twice that to the RIAI cradle-to-grave total, assuming the array is replaced once within the 50-year study period.

The NZCBS also includes a target for energy use intensity (EU), which takes account of all projected final energy use at the meter. This is not to be confused with primary energy, which is the energy use at source, such as the power station. The ultimate 2050 target for EUI of new single homes in the NZCBS is 35 kWh/m2/yr GIA. This house is knocking that target out of the park, with a measured energy usage of 25.7 kWh/m2/yr, and a calculated EUI of 25 kWh/m2/yr.

Selected project details

Client: Niall and Carol Crosson

Architect: Niall Smith Architects

M & E engineer: NRG Panel

Civil / structural engineer: Duffy Chartered engineers

Main contractor, project management and energy consultant: Niall Crosson

Electrical contractor: Halpin Electrical

Plastering: M&P Plastering Limited

Airtightness and insulation contractor: Clíoma House

Stone work: Soden Masonry

Airtightness tester / consultant: 2eva

Passive house certifier: Mead Consulting

Life cycle assessment consultant: Wain Morehead Architects

Build system supplier: Timbertech homes

Airtightness products, thermal breaks, natural insulation and natural paint: Ecological Building Systems

Additional thermal breaks: Armatherm, via Timbertech homes

Insulated foundation system: Kore

Windows and doors: Rationel

Roof lights: Fakro, via Tradecraft

Oak stairs and internal doors: Lynch Joinery

Cladding supplier: Cranwood Industries

Zinc & timber cladding: Fallis Passive

Roofing supplier: Cembrit

Heat pump: Daikin, via NRG Panel

Underfloor heating supplier: NRG Panel

Mechanical ventilation supplier: Brink, via IA Kernohan

Photovoltaics: Ecoplex

Sanitaryware: Sonas

Landscaping and exterior hard finishes: Brackley Landscapes

Kitchen: Liam McDermott Carpentry

Wastewater treatment system: Burke wastewater treatment

Build specs

Building type: Detached 260 m2 timber frame house.

Site type & location: Rural, Cootehill, Co. Cavan.

Completion date: November 2019.

Budget: €300,000 (excludes site, includes professional fees, internal tiles and finishes).

Passive house certification: Passive house classic certified

Space heating demand: 12 kWh/m2/yr

Heat load (state calculation tool, e.g. PHPP): 10 W/m2

Primary energy non-renewable: 60 kWh/m2/yr

Primary energy renewable: N/A – project predated this

Heat loss form factor: 3.15

Overheating: (PHPP) 2 per cent of year above 25˚C

Number of occupants: 2 adults, 3 children & 1 dog

Energy performance coefficient (EPC): -0.157

Carbon performance coefficient (CPC): -0.098

BER: A1 (-23.85 kWh/m2/yr)

Environmental assessment method: N/A

Monitoring results: Indoor environmental quality monitoring not available due to faulty IAQ monitors

Radon: Not monitored

Acoustic test results: Not conducted

Embodied carbon: 378 kg (448 with the PV) CO2e/m2 for life cycle stages A1 through C5. If Module D were included then the figure reduces by a further 86 kgCO2e/m2. Calculated using PHribbon by Wain Morehead Architects Measured energy consumption: 25.7 kWh/m2/yr

(Oct 2023-Oct 2024, figure based on electricity bills and includes hot water, utilities and space heating). Of the proportion of energy used by the heat pump, just over one-third is attributed to hot water, and just under two-thirds is for space heating, based on heat pump data

Energy bills (measured or estimated): €2,115 annual bill from October 2023 to October 2024 for all energy use – including EV charging, space heating, hot water and utilities, exclusive of standing charges and including car charging which accounted for 56.56 per cent of this (based on figures sourced from charging app).

Airtightness: 0.53 ACH at 50 Pa or 0.517m3/m2/hr at 50 Pa

Thermal bridging: Bosig Phonotherm used at critical junctions at all floor-to-ceiling windows and doors, as well as to thermally broken steel columns. Gutex Multitherm applied continuously outside timber frame walls and roof and also in connection to Passive Slab. All thermal bridges assessed by an NSAI approved thermal modeler. Final value: 0.0251 W/mK.

Ground floor: 100 mm reinforced concrete topping, followed underneath by Visqueen vapour barrier, 300 mm EPS 100 and EPS 300 used underneath structural areas Kore Passive Slab (thermal conductivity EPS 100 0.036 W/mK, EPS 300 0.032 W/mK), Visqueen EcoMembrane loose-laid polyethylene DPM, 30-50 mm blinding (3-8 mm) on depth of well compacted hardcore (30-50 mm).

Walls: Factory-built timber frame with either 12 mm Permabase cement board cladding externally or 100 mm plastered Concrete block, 50 mm vented cavity, Solitex Fronta Humida breather membrane sealed with pro clima tapes and seals, 80 mm Gutex Multitherm woodfibre board, 220 mm Gutex Thermofibre blown wood insulation, 12 mm Durelis Vapourblock airtight racking board sealed with Tescon Vana tape, 75 mm service cavity insulated with Thermafleece Cosywool insulation and 15 mm gypsum plaster board internally. U-value: 0.11 W/m2K.

Roof: Cembrit Berona Xtra fibre cement slates externally on 44 x 44 mm battens/counter battens, followed underneath by Solitex Plus Connect breathable roofing underlay with integrated wind-tightness tape to seal laps, 80 mm Gutex Multitherm woodfibre board fixed to roof with Heco Topix screws, 220 mm Gutex Thermofibre blown wood insulation, pro clima Intello Plus Hydrosafe airtightness membrane sealed with Tescon Vana tape, 75 mm service cavity insulated with Thermafleece Cosywool insulation and 15 mm gypsum plaster board internally. U-value: 0.11 W/m2K.

Windows & external doors: Rationel Aura Plus triple glazed aluminium-clad larch windows, with argon filling and an overall U-value of 0.70 W/m2K, g value: 0.5.

Roof windows: 1 x Fakro FTT U6 Thermo triple glazed roof window. U-value: 0.8 W/m2K.

Heating system: Daikin Altherma 3 air-to-water heat pump supplying underfloor heating and 181 litre buffer tank.

Ventilation: Brink Renovent Excellent 400 heat recovery ventilation system — Passive House Institute certified to have heat recovery rate of 84 per cent, and an EN 308 certified efficiency of 93 per cent.

Cooking fumes ventilation: Extract fan attached to Compair Flow Star GTS 150 adaptive airtight valve.

Potable water use: Not calculated.

Electricity generation: 18 x Leapton solar photovoltaic array with an average annual output of 7.2 kW. No storage, prioritised for domestic use and electric car charging, excess electricity exported.

Daylighting: Not calculated.

Material impact: Whole building LCA conducted by Wain Morehead Architects to assess material specification impacts, materials with EPDs specified where possible, and material use minimised through rationalisation of size, compact form and minimisation of underused space (e.g. circulation space) in design. Timber frame using FSC certified timber, all insulation was bio based including Gutex Multitherm boards, blown Gutex Thermofibre, Thermafleece Cosywool sheep’s wool and Combi Jute insulation, Auro clay-based paint.

Image gallery

-

ECO Drawing Set R1-PEW - AR2

ECO Drawing Set R1-PEW - AR2

ECO Drawing Set R1-PEW - AR2

ECO Drawing Set R1-PEW - AR2

-

ECO Drawing Set R1-PEW - AR5

ECO Drawing Set R1-PEW - AR5

ECO Drawing Set R1-PEW - AR5

ECO Drawing Set R1-PEW - AR5

-

PEW-AG-01-Raft Foundation-Rev-B

PEW-AG-01-Raft Foundation-Rev-B

PEW-AG-01-Raft Foundation-Rev-B

PEW-AG-01-Raft Foundation-Rev-B

-

PEW-AR-02-Warm Roof Eaves-Rev-A

PEW-AR-02-Warm Roof Eaves-Rev-A

PEW-AR-02-Warm Roof Eaves-Rev-A

PEW-AR-02-Warm Roof Eaves-Rev-A

-

PEW-AW-07-Window Jamb-Rev-A

PEW-AW-07-Window Jamb-Rev-A

PEW-AW-07-Window Jamb-Rev-A

PEW-AW-07-Window Jamb-Rev-A

-

PEW-WW-01-External Corner-Rev-B

PEW-WW-01-External Corner-Rev-B

PEW-WW-01-External Corner-Rev-B

PEW-WW-01-External Corner-Rev-B

-

Passive EcoWall Details

Passive EcoWall Details

Passive EcoWall Details

Passive EcoWall Details

https://passivehouseplus.co.uk/magazine/new-build/storm-breaker#sigProId7897b55e92