- Case Studies

- Posted

State of the Art

Inside the Lewis Glucksman Eco Gallery, with John Burgess of Arup Consulting

Dan Brown, in his opening chapters of the ‘Da Vinci Code' (ref. 1), describes the onerous environmental control regimes of the Grand Gallery in the Louvre in detail and in doing so has explained, to millions, the need for highly serviced buildings to house art treasures of the world.

Art Galleries by their nature demand a highly controlled environment for the preservation and safe keeping of their art collections. Lighting systems, control of air temperature, humidity and cleanliness, sound/PA systems, security systems, fire protection, amenities for staff and public all play important roles in the successful operation of a gallery capable of accommodating artworks from home and overseas. To provide these services, purpose-built to allow the display of paintings (not pipes!) presents a challenge for any aesthetically minded project team. To also deliver them within tight fiscal limits and in a manner that minimises the environmental footprint of the building places constraints of Houdini-like proportions on the humble building sciences engineer.

The new Lewis Glucksman Art Gallery has presented such challenges and now that the project is completed and was opened on 15 October 2004 , this author is pleased to report that initial building performance exceeds all expectations.

Lewis Glucksman Gallery

The Lewis Glucksman Gallery, located at University College Cork's main entrance on Western Road , is a major new addition to the vibrant cultural life of the Munster region. The gallery, designed by O'Donnell Toumey Architects, is a landmark building with four impressive gallery spaces, lecture facilities, a riverside restaurant and shop. The building floor area is 2300m² spread over 7 floors.

The artistic mission of the Lewis Glucksman Gallery is to explore all aspects of visual culture and present a range of innovative and intellectually stimulating displays. This is reflected in a wide range of exhibitions that span various media and historical periods. As well as providing a dynamic cycle of exhibitions, the Lewis Glucksman Gallery provides many other opportunities to encounter visual art including practical art workshops, film screenings, seminars, lecture series and gallery tours.

Placing the Gallery in an Environmental Context

The natural environment impresses you when you are standing at treetop level watching salmon pushing their way up-river. Then, looking inwards and considering the display of great works of art, one reflects on the inspiration that nature provides the artist.

The Gallery is a twisting, turning, cantilevered structure, anchored into the limestone escarpment at basement level that floats out over the banks of the river. Clad in Carlow limestone and Cedar boarding, the architecture itself succeeds in blending in with the natural environment of the river bank. And it is to the river that the engineers turned their attention to source much of the energy required to heat, cool and provide moisture control in the gallery.

Following on from the ‘ground-breaking' research undertaken in the UCC Geology Dept.,(ref 2), well tests confirmed the availability of a clean, thermally stable water source located in the alluvial gravel deposits to be found deep down in the Lee river basin. During the Pleistocene period, when the ice shelves covered much more of the globe than they do now, sea levels were some 130m lower than they are now and rivers flowed in much deeper valleys. As the ice age ended, water levels rose and gravel deposits were laid down. It is ironic that the recession of the last Ice Age has provided a resource that is being used to limit energy consumption in the new building, the incentive for development of such resource being driven by the impact of global warming today.

In the UCC Art Gallery the engineers have developed Ground Energy Thermal Transfer Systems (GETTS) to minimise energy use in the delivery of heating, ventilation and air conditioning systems for a closely controlled environment. In doing so, energy consumption has been reduced to 25% of the levels expected from conventional chiller and boiler heating systems. A total of 256 tonnes of carbon dioxide emissions per annum has effectively been reduced by the use of the ground energy thermal transfer systems, (ref.3).

The research undertaken on this project will play an important part in defining energy consumption targets for buildings of a similar function. Bespoke civic / public buildings for museums and galleries do not have a readily available record of benchmark energy performance indicators. The design estimates and post-occupancy feedback on energy consumption from this project will provide useful benchmark data for setting the guidelines to be established as part of the impending EU Directive regarding Energy Performance in Buildings. In a way, the UCC Lewis Glucksman Art Gallery will set the standards for others buildings of a similar nature to follow.

Description of Services Installations

HVAC (Heating Ventilation & Air-Conditioning)

The HVAC systems have been selected from a palette of innovative technologies, carefully adapted to match the requirements of each space while optimising the benefits of energy efficient solutions. The main source of heating and cooling is provided by the Ground Energy Thermal Transfer System (GETTS). Two water-cooled chillers generate both chilled water at 6°C and heating water at 45°C (30°C when providing cooling only) at the same time. The heat of rejection from the cooling process is fed directly into the heating circuits. Excess heat or coolth is transferred to ground water through a plate heat exchanger. The ground water is sourced from two 12 metre deep wells and is discharged to a holding tank for use in toilet flushing and landscape irrigation. Excess water is discharged to river. A thorough review and design adaptation of Dunstar's (Clonakilty) Ground Source Heat Pump (GSHP) proposals for the project was undertaken to match the equipment to the unusual demands of the project. At a capacity of 170kW cooling and 200kW heating, this is the largest GSHP application in the country.

Ventilation is supplied to the galleries at low level using discreet building elements such as the lower steps on stairs, window floor boxes and locker cabinet pedestals. Overhead grilles or wall nozzle diffusers were brushed over in a bid to keep ceilings and walls free from intrusion. In spite of this, ventilation rates of 6 air changes per hour are delivered by air handling units (AHUs) located in mezzanine plantrooms. AHU components have been selected to maximise the available cooling and heating energies generated by the GETTS.

With reference to figure 1, one of the modes of operation frequently used in the summer months is dehumidification. With a space setpoint of 50% Relative Humidity (RH) at 21°C and ambient levels of 75 to 90%RH, the AHUs must operate both cooling coils (to strip out moisture) and re-heating coils to raise air temperatures back up to room supply setpoint. As the GETTS provides both chilled water and heating water simultaneously from the water cooled chillers, a high Coefficient of Performance (CoP) of 8 can be achieved. In other words, 8 kW of cooling and heating energy is provided for every 1 kW of electrical power used in the chillers. Conventional systems would use a gas fired heating plant in tandem with the chilled water plant to do the same, thereby burning copius amount of gas in the summer!! On top of this, when RH control is not required, the ventilation systems maximises the opportunity for ‘free' outside air cooling as the minimum air supply temperature to the space is 19°C.

The entrance foyer to the gallery introduces visitors to the undercroft of the gallery spaces. Use of planar glazing allows passers-by to view in and up to the galleries. Trench heating and lighting located at the base of the showcase glazing complements the effect in an inconspicuous manner. Radiant panels are used to offset the risk of condensation. Underfloor heating is also provided for in the foyer and in the public toilets. Gas-fired boilers provide back-up to the GETTS and high- temperature water for the trench heating and radiant panels.

All systems have been designed to minimise noise intrusion to the gallery space. This results in larger, low velocity, duct distribution systems and acoustic attenuation on all plant, including the use of specially lined drainage systems. Despite the minimalist approach to the provision of the 3 R's (Rooms, Routes and Risers), the services have been threaded through the building fabric, using normally out-of-bounds zones such as the space between floor, wall and ceiling joists. This provided a challenge to all who worked on the installation of the systems, requiring a very close team effort in the coordination of both spatial and programme issues.

The HVAC systems are controlled by a Building Management System (BMS). Triple redundancy temperature and humidity control is provided for each of the gallery spaces. Despite the use of an energy efficient GETTS, the BMS plays an important role in providing the user with flexibility in defining space requirements. During idle periods in the gallery calendar, the HVAC plant can be set to operate even more efficiently by relaxing the close tolerances on temperature and RH. The BMS also monitors energy consumption information provided from electrical and gas metering devices selected to monitor key elements of the installation. This information will feed back into the design team to verify and / or adjust the findings of design studies undertaken early in the conceptual stages of the project.

Lighting

Day light is permitted in the wrap-around galleries that surround a special purpose, windowless room for collections sensitive to natural light. All glazing in the gallery areas are fitted with motorized blinds to facilitate control when daylight penetration is not desired. Bespoke lighting for all internal and external elements of the building provides for user control of the lighting themes in the galleries while accentuating the architectural features in a sympathetic manner. The lighting of external gallery walls comprises recessed ceiling mounted, fluorescent wall washers with UV filters. The wall washers are arranged in a continuous linear array along perimeter gallery walls to provide a uniform light wash over the walls. A hidden, recessed lighting track is provided for luminaires to illuminate free standing exhibits on the gallery floor.

An alternative lighting scheme illuminates the internal walls to provide contrast within the gallery space. These walls are illuminated using tungsten halogen spotlights, fitted with a UV filter lens and sculpture lens, adjustable to provide flexibility to suit the particular exhibits on show.

All luminaires in the gallery areas are fully dimmable. A programmable automatic analogue lighting control system is used to provide a number of scene settings to suit various occasions. Local controllers are installed in each of the galleries to enable the curators to change settings as required. The system can also be used to provide security lighting and is linked to the building's intruder alarm system.

Security Systems

A multi-zone intruder alarm system has been installed throughout the building and provides for separation of gallery and restaurant use. A Telexper Digital Video Recording (DVR) system provides for the following functions: Video multiplexer, video recording, event logger for motion detection and alarm, archiving, TCP/IP Networking, and Remote Access.

The alarm function is particularly useful as cameras can be used to detect motion enabling security personnel to immediately view cameras in the triggered alarm area. The system is connected to the site security system via the site IT Network over fibre-optic cable to facilitate remote monitoring of the building.

Fire Systems

A Category L1 fire detection and alarm system is installed throughout with due consideration for aesthetic requirements in the public and gallery spaces. An aspirating smoke detection system is provided for in the special collections room to ensure early detection of smoke emissions. A halogen free (zero ozone depletion potential) FM200 fire suppression system is installed in the Gallery store.

Power Systems

The Main Low Voltage Panel in the basement feeds local power and lighting to sub-distribution boards throughout the building. The main panel has a facility for generator backup connection. All galleries have floor outlets concealed within the timber floor for future display of freestanding exhibits

Conclusion

From a HVAC perspective, the gallery's environmental criteria, as agreed in the original client brief, was to provide for close control of temperature and humidity in the one of the internal gallery rooms with the remaining galleries being provided for by natural ventilation and heating.

The project has been completed within budget and exceeds all aspects of the client brief . Close control of the room conditions (temperature, humidity, noise and lighting) within all galleries and the art store has been achieved through the use of innovative technologies.

The project will provide a prestigious cultural resource for the Cork area that can also be used to demonstrate the successful implementation of energy efficient technologies. Energy use and carbon dioxide emissions have been reduced to 25% of that of conventional systems, from 352 to 95 tonnes of CO2 per annum, an important and tangible benefit in helping Ireland meet its commitments under the Kyoto protocol. The building is well equipped to meet the requirements of the forthcoming EU Energy Performance in Buildings Directive.

The role of the Building Sciences Engineer is crucial in assessing economic and environmental impact of the innovative technologies and in ensuring the safe and efficient implementation and operation of these systems.

The external appearance of the building has not been affected in any way by the mechanical services. Passers-by will not be able to see or hear the systems that are working away to provide a high spec controlled environment for the galleries, restaurant and kitchens. Visitors will not appreciate the vast array of systems that have been installed to permit this gallery to operate at the demanding requirements of the international stage. But it would be out of place to expect anything else, as the whole point of the Gallery is to see Paintings not Pipes.

References:

• Da Vinci Code – Dan Brown - 2003

• Shallow Gravel Aquifers and the Urban ‘Heat Island' Effect: a Source of Low Enthalpy Geothermal Energy - Professor Alistair Allen, Dejan Mellinick – UCC, Paul Sikorra – Dunstar. Geothermics 32 (2003) 569-578

• UCC Art Gallery Report to Sustainable Energy Ireland on Energy Saving Initiatives – Arup Consulting Engineers – April 2002

Client : University College Cork

Design Team

Architects : O'Donnell Tuomey

Structural Engineers : Horgan Lynch

Services Engineers : Arup Consulting Engineers

Quantity Surveyors : AKC

Fire Consultant: Cantwell Keogh

Kitchen Consultant: QA Design

Acoustic Consultants: AWN

Landscape Consultants : Brady Shipman Martin

Contractors

Main Contractor: PJ Hegarty

Mechanical Contractor: Mercury Engineering

Electrical Contractor: IIF Process and Mechanical Contractors

Lifts Contractor: Ennis Lifts

Kitchen Contractor: Brodericks

Ground Source Heatpump Contractor: Dunstar Energy

Related items

-

Air tightness training course to launch in Carlow this March

-

Why airtightness, moisture and ventilation matter for passive house

Why airtightness, moisture and ventilation matter for passive house -

Airtight delight

Airtight delight -

Partel’s airtight membranes now certified for passive house construction

Partel’s airtight membranes now certified for passive house construction -

ProAir pioneers with EPDs for ventilation systems

ProAir pioneers with EPDs for ventilation systems -

Mass timber masterwork

Mass timber masterwork -

Partel obtains EPDs for airtight membranes

Partel obtains EPDs for airtight membranes -

Let’s bring ventilation in from the cold

Let’s bring ventilation in from the cold -

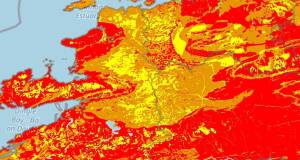

45,000 more Irish homes face radon risk, new maps reveal

45,000 more Irish homes face radon risk, new maps reveal -

ProAir retooling for the future

ProAir retooling for the future -

Manhattan modular apartments feature Wraptite membrane

Manhattan modular apartments feature Wraptite membrane -

Ecological launch Inventer decentralised ventilation

Ecological launch Inventer decentralised ventilation