- New build

- Posted

Stylish low energy house squeezed into South Dublin garden

Built in the back garden of two architects, this simple-but-elegant brick house in Blackrock faced the twin challenges of an extremely tight site and less-than-ideal orientation, but with rigorous attention to detail it came close to passive house levels - while delivering impressively low actual heating costs.

Click here for project specs and suppliers

This article was originally published in issue 17 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

A new build in Blackrock, Co. Dublin shows how to do low energy, open plan living on a really, really tight site.

Architect couple Liz and Frank Hughes live on Prince Edward Terrace in a protected house dating from 1842. Frank, now retired, explains that after the children had left, the four-bedroom house began to feel a bit too big.

“It’s also high maintenance,” he explains. “We have timber windows that have to be painted, and a slated roof. But we also had a store at the end of the garden which gave us access to Brookfield Terrace, behind our street. We decided, why not lodge for planning permission to build a house down there?”

The couple sought and received planning permission for a three-bedroom, open-plan house fronting onto Brookfield Terrace.

Passive House designer Liz, who took charge of the design of the new house, explains that onsite restrictions meant the ideal southern orientation wasn’t an option.

“Instead, the bedrooms and bathrooms face east, and then the living area faces west. As a result we were penalised in the passive house software, PHPP, but on reflection, a full south orientation may have given us too much solar gain. As it stands, overheating is not an issue.” To help mitigate the slightly increased power load as a result of the sub-optimal orientation, the couple plan to install a photovoltaic array on the roof.

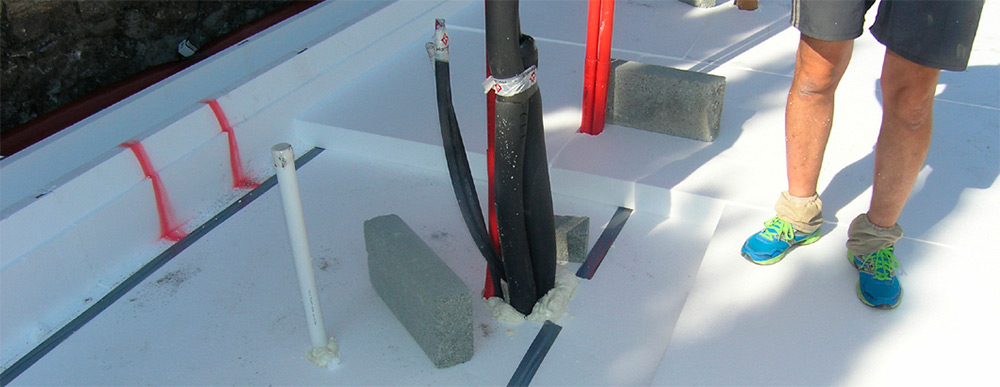

The Supergrund foundation system features three layers of EPS 100 insulation, with the bottom layer shown here with joints taped, and foam filling around service penetrations

The taped second layer of EPS, before channels are cut to contain heat recovery ducts and then the top layer of 100mm EPS laid over

Installation almost complete of the reinforced steel mesh for the concrete slab, with underfloor heating also installed

The decision to go for a timber frame structure was informed partially by environmental concerns and partially by the advantages of off-site manufacture. “You get greater quality control because you’re building the panels in a factory setting,” says Liz, “plus you get rapid onsite construction.

Data from the heat pump reveals the house cost €118 to heat in its first year of occupancy.

Almost 80 per cent of the wall can contain insulation, and there’s enhanced vapour transfer technology in it as well.”

The frame came from Wexford Timber Frame Homes, which is run by Ivor Gilbert.

Erection of the timber frame, with the gable panel craned into place

Ridge beam in place

I-beams laid out in front part of roof

Intello vapour barrier and Gutex Ultratherm insulation fixed to underside of roof beams

He says that one of the key challenges on the build was simply craning the panels into place in what was an exceptionally tight space. Having a highly skilled, highly motivated crane driver became very important.

“Access was a very big thing,” he says. “We had to work between three different sets of cables and the crane only had 100mm tolerance in the turn. Had it been any tighter, we wouldn’t have been able to do it.”

The timber frame panels themselves are twin stud. Typically, Gilbert’s panels are manufactured with cellulose insulation pumped into the cavity, but Liz Hughes opted instead to use solid Thermo-Hemp insulation batts. Ivor Gilbert says that as a result, the panels themselves had to be manufactured in a slightly unusual way.

“Fitting the insulation into the twin wall was a challenge because we wanted to avoid cutting the insulation as much as possible.

Half the panel was made and insulated, then the second half of the twin wall was made on top of that, with the full piece of insulation in between.”

Liz Hughes explains that she sought this build-up primarily because she was familiar with the Thermo-Hemp product. She and Frank had used it in remedial works on their existing home, and liked the fact that it was both rigid and breathable. Aesthetics also required remarkable precision in the manufacture of the timber frame. Ivor Gilbert says that Frank and Liz wanted the window opes completed without cutting any of the bricks in the external leaf.

That meant that the opes in the frame had to match the brickwork to within the millimetre.

“We make whatever somebody wants,” he says. “There was a vast amount of contact between ourselves and the client, making sure every detail was tried and tested before we made anything.”

That level of forethought was also necessary when it came to negotiating existing garden walls that had to be retained on either side of the new building. “We had to make sure that moisture didn’t get from the existing garden wall into the new structure,” says Liz. In addition, the design and build teams had to ensure that the cavity between the external leaf and the timber frame was properly ventilated.

The solution was to install a gutter on top of the garden walls on either side of the structure, and ventilate the cavity from those walls upwards.

The spacious, open-plan living room steps down into the back garden via large, sliding glass panels. The design team had hoped to create a continuous glazed wall at this elevation, but at the time, there was no product with sufficient thermal properties to make this vision a reality.

“We just couldn’t get a sliding, folding screen that met passive standards,” says Liz. “We hoped that it would become a garden room when the screens were folded back but that wasn’t going to happen. In the end, we installed two substantial sliding door screens from NorDan that we’re very happy with.”

The airtightness result fell just at the limit of the passive threshold, at 0.64 ACH at 50 Pa, as measured by airtightness consultants 2eva.ie. Ivor Gilbert reports that installing the engineered timber I-joists which comprised the rafters resulted in a tear in the airtightness membrane.

“The I-joists are very long, they’re actually the full length of the house. During the build, we had a person stationed at each end to move them up into position. But as they were moved along, they caught the airtightness membrane and cut it.” The problem was revealed at the first blower door test and was quickly remedied, resulting in a much better airtightness result on the second test.

The house is heated by a Daikin Altherma air-to-water heat pump with an inverter capable of modulating down to the low outputs required for near passive builds. This feeds into underfloor heating in the ground floor, and Irish-made Solorad hydronic heaters – a low water content fan assisted system – to the first floor, with Heatmiser programmable timed zoned controls. Each Solorad is its own zone, explains Solorad’s Rory Farrelly.

“There are two temperature sensors on each radiator – one on the coil which turns the fans on when the water reaches 26C, the other on the return air. It takes the temperature of the air in the room, and once it reaches the desired temperature each rad turns off.”

Liz and Frank are eager to praise Keltic Renewables — who supplied and installed the heating and ventilation systems — and contractor Kevin Doyle of Doyson Construction, for the success of the project. Liz says of Kevin: “He is experienced in passive house design, and he also understood the science of the building. His attention to detail and his organisation of things was impressive.”

Though Frank and Liz remain in the original family home, they plan to move into the new house within the next couple of years. Right now, their daughter and her boyfriend are living there. She reports that the house is very easy to live in, and that the air quality is excellent.

Because all space and water heating comes from the air-to-water heat pump, there’s only one bill to pay. It’s cheap to run — and once the PV panels are installed, it will become cheaper still.

When Passive House Plus asked if this low running cost claim could be quantified, Diarmuid Jones of Keltic Renewables came up trumps. The Daikin Altherma heat pump that covers the building’s thermal loads logs electrical input and thermal output – including separate figures for heating and hot water. In the first 12 months to June this year, the 130 sqm home consumed 741 kWh of electricity to generate 3,119 kWh for space heating. The heat pump’s actual space heating output – at a measured coefficient of performance (COP) of 4.21 – works out at just under 24 kWh/m2/yr – within a hair’s breadth of the value calculated by PHPP. “We’re running the system on weather compensation between 25 and 40C flow temperatures for heating,” said Jones. As is typically the case with passive and near passive buildings, domestic hot water is the bigger load. The heat pump used 1,295 kWh of electricity to generate 3,609 kWh of hot water – a measured COP of 2.79. But what does this mean in terms of running costs? According to Jones, based on an assumed average unit price of €0.16C per kWh, the house is costing €118 per year to heat, with an additional €207 for hot water. Not too shabby at all.

Selected project details

Architect: Liz Hughes Architect

Main contractor: Doyson Construction

Timber frame: Wexford Timber Frame Homes

Quantity surveyor: Neil Ryan Quantity Surveying & Cost Consultants

Mechanical contractor: Keltic Renewables

Electrical contractor: Jim Dunne Electrical

Airtightness testing: 2eva.ie

Wood fibre & hemp insulations: Ecological Building Systems

Roof insulation: Knauf

Ground floor insulation: Kingspan Aerobord

Airtightness products: Ecological Building Systems

Windows & doors: NorDan Vinduer

Roof windows: Velux

Floor slab design: Tanner Structural Design

Civil engineering: Dennis Campbell Engineer

Passive house consultant: Building Life Consultancy

BER: 2eva.ie

Heat pump: Keltic Renewables

MVHR: Keltic Renewables

Hydronic heating system: Solorad

Lighting: Hicken Lighting

Fibre cement slates: Tegral

Additional info

Building type: 130 square metre detached two-storey timber frame house

Location: Brookfield Terrace, Blackrock, Co Dublin

Completion date: April 2015

Passive house certification: Not certifiable

Space heating demand (PHPP): 23 kWh/m2/yr

Heat load (PHPP): 12/W/m2

Primary energy demand (PHPP): 113 kWh/m2/yr

Airtightness: 0.64 ACH at 50 Pa BER: A2 (42.93 kWh/m2/yr)

Thermal bridging: Entire timber frame insulated to cut thermal bridging

Ground floor: Kingspan Aerobord Supergrund insulated floor system including ring beam to design and reinforcement as per Kingspan Aerobord specification, with 100mm thick reinforced concrete slab and 3 x layers of EPS/100 insulation, on 30mm sand blinding, on radon barrier on 200mm blinded and compacted hardcore. U-value: 0.114 W/m2K

Walls: Gables have 20mm smooth sand/ cement plaster with K-Rend finish to 100mm concrete block outer leaf. Walls elsewhere have 102.5mm brick outer leaf. All walls to have 50mm ventilated and drained cavities. Pro Clima Solitex Plus breather membrane laid over 12mm Spano Durelis Populair board, fixed to 300mm deep twin-stud factory made timber frame with 300mm Thermo-Hemp between studs. Pro Clima Intello Plus breathable vapour barrier fixed to inner face of studs to provide a complete seal. Service space has 40mm Thermo-Hemp behind 12.5mm skimmed plasterboard internally. U-value: 0.125 W/m2K

Roof: Tegral Riverdale fibre cement slates on 50x38mm sw battens fixed to 50x38mm sw counter battens providing ventilated air gap, on Pro Clima Solitex Plus breather felt, on 50mm Gutex Ultratherm insulation fixed to 350 x 47mm timber I-beams with 2 x layers of 180mm Knauf Earthwool MetStud insulation between beams. Pro Clima Intello Plus breathable vapour barrier fixed to u/s of beams. Service space has 40mm Thermo-Hemp insulation behind 12.5mm skimmed plasterboard ceiling. U-value: 0.084 W/m2K

Windows: NorDan N Tech Passive triple-glazed aluclad pine windows with low emissivity glass and argon filled cavities. Overall U-value: 0.7 W/m2K

Roof windows: Velux triple-glazed roof lights with solar-powered actuators triggered by rain sensors. Overall U-value: 0.89 W/m2K. Additional insulating value from automated black out blinds.

Heating system: Daikin Altherma air-to-water heat pump with factory insulated hot water cylinder. SPF: 418 % when tested to EN14511-2:2000(electric). Underfloor heating to ground floor, Solorad hydronic heaters to first floor

Ventilation: Vent-Axia Sentinel Kinetic Plus with Nilair ducting system. Thermal efficiency 91%. Specific fan power 0.52 W/I/S (Sap Appendix Q)

Green materials: Timber frame, wood-based Gutex Ultratherm and Durelis Populair boards, Thermo-Hemp insulation board, NorDan alu-clad pine windows from PEFC sources, Knauf Earthwool MetStud made with ECOSE technology, a formaldehyde free binder derived from renewable materials.