- Insulation

- Posted

Breaking the mould - part IV

In the fourth part of a series of articles on the condensation risks associated with insulating single lead dwellings, Joseph Little of Joseph Little Architects & Building Life Consultancy reveals serious problems with the approach taken by regulators, standards authorities and suppliers on the condensation risks associated with insulating single leaf walls.

The stakes are high

This series of articles was written to explore the range of issues associated with upgrading single leaf walls with a focus on occupant and building health as much as energy, just as the Home Energy Saving scheme was launched. A year on from the first article the need for greater understanding and clear guidance for the industry is greater than ever. This is because the government’s Energy Demand Reduction Target programme is bringing energy utilities such as ESB and Bord Gáis into the refurbishment market.

With their huge client bases, sophisticated billing systems and a variety of ways of helping homeowners fund energy-efficient upgrades (such as the ‘save as you pay’ concept) the number of dwellings that will be upgraded is likely to increase significantly and a wider demographic of occupants are likely to be involved. We understand the precise mechanisms and source of funding are still being discussed with government departments. Halo, an ESB initiative, is offering free house surveys and has orchestrated a limited number of refurbishments so far. Bord Gáis has promised to launch the first stage of their initiative in early 2010.

Figure 1: The cover of Halo’s survey brochure courtesy of ESB

While SEI (through the HES scheme), ESB (through Halo) and no doubt Bord Gáis are rightly focused on appropriate specification and quality, it is interesting to note that the first two organisations have effectively removed architects – who, with their training, experience and professional indemnity insurance, are the usual source of specification and inspectors of quality in Ireland – from the refurbishment schemes they have created. This means that the onus on those organisations to get their own specification right and to control quality is higher than usual. Given how seldom building fabric tends to be significantly refurbished in existing buildings, and given the carbon-neutral goal of 2050 and rising fuel prices, it may be argued that there will never be an opportunity to make as big an impact on energy use within the Irish housing stock again. The need to do so in a healthy, appropriate way is paramount.

This article and the next in the series, which will be published in the next edition of Construct Ireland, should ideally be read together. This article discusses the standards used to evaluate interstitial condensation, key issues that effect mould within walls, preparing a wall for dry-lining and evaluating hygrothermal simulations. The next article then moves from there to evaluate a series of comparative simulations of different types of single leaf wall upgrades under different conditions, including di

Read the full Breaking the mould series

Part 1 -

Part 2 -

Part 3 -

Part 4 -

Part 5

Figure 4: Mould and dampness revealed behind a dry-lined wall in a cellar

Condensation assessment – which approach?

A major challenge for any specifier in the new refurbishment market is to assess the appropriateness of one build-up and specification over another. Without the ability (resources or time) to do primary research and without sophisticated simulation software architects and builders generally rely on data supplied by standards authorities and suppliers, backed up by codes. But is that always good enough? What’s the quality of the information?

In relation to condensation risk, the relevant document of a standards authority (such as an Agrément certificate) issued anytime in the last seven years is likely to state something like this: “The design will include for […] minimising risk of condensation in accordance with the recommendations of BS 5250: 2002 - Code of practice for control of condensation in buildings.”

In the case of a supplier the relevant portion of the brochure could state that their “technical service department can provide a condensation risk analysis of your proposed design. Alternatively, the designer can undertake an independent assessment by following the procedures set out in BS 5250: 2002.”

Or it could state:

When insulating buildings the recommendations of “I.S. EN 13788: 2001 – Hydrothermal performance of building components and building elements – internal surface temperature to avoid critical surface humidity and interstitial condensation – calculation methods” should be followed to minimise the risk of condensation within the building elements and structures.

BS 5250 defines the issues, parameters and terms in relation to condensation in buildings and shows some calculations. IS EN 13788 “gives calculation methods for the internal surface temperature… below which mould growth is likely, given the internal temperature and relative humidity” and “the risk of interstitial condensation due to water vapour diffusion.” It appears that the calculation methods usually selected for use from these documents are:

(a) The establishment of the temperature factor (fRsi) to determine likelihood of surface condensation as set out in Annex D.2 of BS 5250 (also found in appendix D of TGD L), and

(b) The Glaser or dew point method for assessing ‘the risk of interstitial condensation due to water vapour diffusion’ in Section 6 of IS EN 13788. The Glaser method itself has been used for decades and is a well-established tool in the construction industry (see figure 2 below).

Figure 2: A typical graph generated using the Glaser method showing temperature and vapour pressure profiles across a multi-layer building element

IS EN 13788 also refers briefly in annex F to more advanced calculation models; computer models and a version of the Glaser method which makes an allowance for moisture redistribution in the liquid phase (in other words capillary action). It is unlikely that a supplier making reference to an analysis under IS EN 13788 (as quoted above) would be referring to use of the annex F models as they are barely sketched out in that document. This author would be very interested to hear from insulation suppliers that use a wider range of assessment methods than (a) and (b) listed above.

Time waits for no standard

The collective impact of further growth in understanding of building physics, increased processing power and the development of sophisticated simulations software since those documents were published requires a re-appraisal of how and when we use them. The creators of those documents would agree to this as they were very clear on the limitations of the calculation methods they set out and knew that numerical simulation would allow far greater accuracy once the input data was better known.

Complex phenomena, such as liquid water movement under temperature gradients, are becoming better understood and a number of computer models that can give reliable performance predictions are currently under development and in use by consultants. Work is under way to standardize these and develop a formal protocol for the assessment of structures.

BS 5250, footnote, p7

Therefore this standard lays down simplified calculation methods, based on experience and commonly accepted knowledge. The standardisation of these calculation methods does not exclude use of more advanced methods.

IS EN 13788, introduction, p3

The [Glaser] method should be regarded as an assessment rather than as an accurate prediction tool... It does not provide an accurate prediction of moisture conditions within the structure under service conditions.

IS EN 13788, section 6.1, p12

The computer models and accurate prediction tools reffered to above are now available for use by specifiers and suppliers. IS EN 15026 (2007) is the protocol they adhere to. Ashrae (the American Society of Heating, Refrigerating and Air-Conditioning Engineers) standard 160P is the US equivalent.

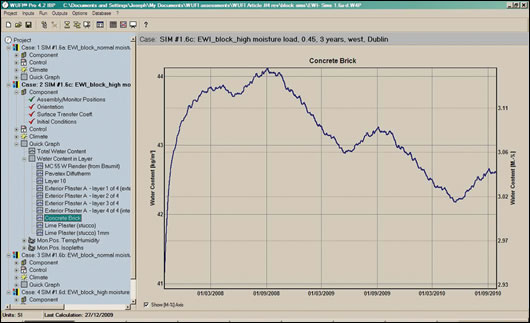

Wufi from the Fraunhofer Institute and Delphin from the University of Dresden are two leading examples of hygrothermal simulation software. See a screen shot of the Wufi interface figure 3 below. Germany and the USA each have more than 1,000 licensed users of Wufi, Poland and Canada have more than 500 each, the UK has no more than 100 users and Ireland (at last count) had two registered users: one of them supplies insulation, the other is this author. It is likely numerous trial versions have been downloaded in Ireland however. Nonetheless Professor Künzel of the Fraunhofer Institute is at a loss to understand the lack of awareness, or interest, in numerical hygrothermal simulation of building fabric on these Isles.

Figure 3: Screen image from WUFI showing moisture content dropping in the concrete block of a wall insulated externally

It is clear then that numerical simulation is becoming well-established elsewhere. The following quote from the 2009 edition of Ashrae’s Fundamentals handbook shows the current down-graded status of Glaser in the USA:

[Ashrae] does not recommend the dew point calculation as the sole basis for hygrothermal design of building envelope assemblies… The dew point method is presented here for reasons of historical continuity, and because it serves as an illustration of the fundamental principles of conduction of heat transport and diffusion in moisture transport.

Ashrae handbook – Fundamentals (2009) p27

The Introduction to IS EN 15026 gives a useful summary of the differences between a condensation prediction under that standard and an assessment using the Glaser method:

This standard [15026] defines the practical application of hygrothermal simulation software used to predict one-dimensional transient heat and moisture transfer in multi-layer building envelope components subjected to non-steady climate conditions on either side […] While the Glaser method considers only steady-state conduction of heat and vapour diffusion, the transient models covered in this standard take account of heat and moisture storage, latent heat effects, and liquid and convective transport under realistic boundary and initial conditions. The application of such models has become widely used in building practice in recent years, resulting in a significant improvement in the accuracy and reproducibility of hygrothermal simulation.

IS EN 15026, introduction, p4

IS EN 15026 and one-dimensional numerical simulators like Wufi Pro are themselves a step along on the way. Future standards will take account of issues these don’t deal with such as convection through holes and cracks, and important two-dimensional effects such as rising damp and conditions around thermal bridges. Wufi 2D and Wufi Plus are already moving beyond the likes of IS EN 15026 to allow simulation of these issues too. However one-dimensional numerical simulation is becoming and will then remain the main tool for day-to-day assessment. The kind of questions it allows to be studied and the degree of accuracy it delivers could only have been dreamed of by Glaser when he first formulated his method decades ago.

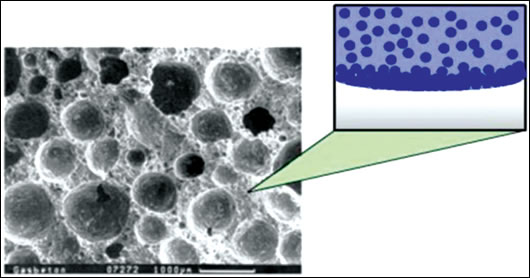

Figure 6: pores of a solid material can contain water as both vapour & liquid

Image: Fraunhofer Institute, IBP Holzkirchen

Glaser and solid walls

As the refurbishment market grows it is of key importance that the industry recognises that single leaf wall structures are the least suitable form of construction to evaluate using the Glaser method. This is because that method does not deal with a range of issues that are of great importance in single leaf walls including:

a) The dependence of thermal conductivity on moisture content

b) The release and absorption of latent heat

c) The variation of material properties with moisture content

d) Capillary suction and liquid moisture transfer within materials

e) Air movement through cracks or within air spaces

f) The hygroscopic moisture capacity of materials

Consequently the method is applicable only to structures where these effects are negligible.

IS EN 13788, scope, p4

Furthermore, since the method only considers steady-state transport under heavily simplified boundary conditions, it cannot reproduce individual short-term events or allow for rain and solar radiation.

HM Künzel

As explained in the first article in this series, a single leaf external wall must act structurally; enclosing a body of air and slowing heat loss, while dealing with humidity on the inside, and sun, rain and more humidity on the outside. Insulating the wall on the inside, regardless of insulation type, complicates the issue as drying to the inside is reduced, the temperature gradient within the masonry substrate flattens and the substrate usually becomes wetter – which also affects its thermal conductivity. Items a, c, d, e and f are important features in any single leaf masonry wall (made up of plasters and stone, concrete or brick) which is then insulated either internally or externally. Item b can be important for fibrous insulants. It is clear from the above quoted scope of IS EN 13788 that its authors saw the standard and the Glaser (or dew point) method within it as chiefly being of value in assessing light-weight structures and never intended them to be used for single leaf masonry walls.

On a side note it is arguable that the Glaser method may give reasonably close results in analyzing condensation risk of cavity walls, even though most of the issues (a, c, d, e and f) still apply. This is because the cavity is ventilated and the outer leaf deals with driving rain. However the more the cavity ventilation is compromised, or reduced through filling, the less this may be true.

In the context of all this it seems obvious that the use of the Glaser method in the Irish construction industry needs to be limited to the areas for which ISEN 13788 intended it. It also seems obvious that IS EN 15026 needs to be referenced in the upcoming revision to TGD L, and that hygrothermal numerical simulation software should become the main tool used to analyze condensation risk for dry-lining and external wall insulation projects, before approving those systems for the market.

In the mean time we offer the following advice to specifiers who require technical support from insulation companies that supply external or internal wall insulation under current technical approvals: insist that the supplier simulates and analyses the hygrothermal impact of the desired specification for the actual site the building is located on, using local (design year) weather conditions and internal climate conditions, all as prescribed by IS EN 15026. That is the best way to serve your client and reduce the risk of being sued in the future if a refurbishment proves faulted. If the technical department tells you that they carry-out assessments under BS 5250 or IS EN 13788 it usually means Glaser.

Relative humidity and mould

Mould spores are everywhere in the atmosphere, but only grow where they find the nutrition, oxygen, the right temperature and usually but not always moisture. As many building materials provide nutrition for mould, as oxygen is effectively everywhere and external walls are heated by the rooms they bound, many of the conditions are always in place for mould growth in our walls. In old uninsulated walls the temperature difference between the room and the wall surface (circa 4.5 to 5.5K) meant that the most likely place for mould was on the wall finish, probably in a corner behind a cupboard or bed where air currents were less likely to reach the condensation. Where refurbished houses are properly ventilated and the temperature of insulated wall surfaces rise to within a degree of the room temperature it becomes less likely that mould will occur on the surface. Instead we need to look at the conditions within or behind the specified dry-lining. Clearly mould can spread much farther in those circumstances before being noticed.

Careful assembly of a wall build-up, control of interstitial condensation, reduction of nutrients and an alkaline environment are some of the best ways to prevent mould growth.

Studies have shown that moulds do not require the presence of water, but can germinate and grow if the relative humidity at a surface rises above 80 per cent. This is a considerably less severe criterion than the 100% RH [relative humidity] required for surface condensation to occur.

BS 5250, 6.3, Mould growth, p8

The Fraunhofer Institute has undertaken extensive studies to establish the conditions under which different moulds occur. The 80 per cent rule, referenced above, remains a useful guide but a quick glance at the curved lines or ‘isopleths’ in figure 05 below show that mould can occur in a biodegradable substrate at 74 per cent RH at 20°C for instance. One of the key outputs from a simulation using Wufi Pro is a similar chart for every monitored position in the simulated build-up. Thus one can assess the likelihood of mould at any point through the actual construction. It is worth noting however that 80 per cent RH is not unusual as an average value for the whole build-up including outer surface. In fact it is known as the reference water content (or w80) because it corresponds to the normal equilibrium moisture within an existing portion of the building fabric over a year.

Figure 5: hygrothermal conditions favouring mould growth

Substrate groups:

LIMBAU II

non-biodegradable substrates (such as mineral board materials)

LIMBAU I

biodegradable substrates (such as wood & wall paper)

LIM 0

(biological full medium)

Image: Fraunhofer Institute, IBP Holzkirchen

But how can relative humidity affect a solid building material?

The reason it can is because most materials are somewhat porous. A concrete block can be about 13 per cent porous, a brick can be between 25 to 33 per cent porous and mineral wool can be 95 per cent porous. The relative humidity in a porous material is the relative humidity of the air within its pores.

However, because of the intense interaction between the pore air and the pore walls which may have a considerable surface area, the relative humidity of the pore air has a strong influence on the water content of the material. This water content may be much larger than just the water vapour content of the pore air.

The building material gains or loses moisture till it is in equilibrium with the relative humidity of the pore air.

The Moisture storage function describes the amount of moisture taken up in this manner by the building material if it is exposed to air with a specific RH. Since this relationship between RH and moisture content is largely temperature-independent, the RH is an important and unique parameter describing the moisture content of a material.

Wufi online help

Any reader who remembers the query in the first Breaking the mould article about how the 1mm of mineral wool nearest the masonry substrate (in a dry-lining application) could gain so much water, so fast, may now understand better what happened by looking at figure 07 below. When the pore air within the material was at 80 per cent RH the material contained 12 kg/m3 of water, at 96 per cent RH the pores are almost filled with water and the material contains 50 kg/m3 but at 100 per cent RH all pores are filled and all fibres are super-saturated: moisture content reaches 500 kg/m3 of water. Given that the material itself under dry conditions has a density of 70 kg/m3 it is clear that a relative humidity of 100 per cent leaves it a sodden, collapsed mess. However as Dr Daniel Zirkelbach of the Fraunhofer Institute pragmatically suggested to this author, as long as this 1mm dries out completely every summer, reducing the chance of mould, it may not be such a problem that it loses its insulating characteristics in its buffering role – as long as the other 99mm of insulation continue to function properly.

Figure 7: graph showing the moisture storage function of a material

Image: Fraunhofer Institute, IBP Holzkirchen

It can be seen that conditions change as the relative humidity changes and that this takes time. This is good news for specifiers.

The Glaser method, on the other hand, simply assumes that 100% RH are reached instantly, it doesn't consider the necessity to actually move water in order to reach the moisture content that corresponds to 100% RH.

Wufi online help

Furthermore capillary action, one of the mechanisms not measured by Glaser, can act as a safety mechanism in dry-lining. Capillary action can work contrary to the direction of vapour diffusion, ‘wicking’ moisture from a critical spot, thereby by reducing the local relative humidity.

This effect actively works against local water build-up, so that 100% RH can't be reached easily. Of course, you may get water accumulation in your building component if conditions are right (or wrong). But this will rarely be accompanied by 100% RH. If you see relative humidity approaching 100% somewhere in your component, it's probably much too late.

Wufi online help

A code of practice & preparing a wall for insulation

A code of practice for refurbishing historic buildings is currently being prepared for the Department of the Environment. We’re not aware what boundaries have been set as to which building types and eras are to be included and which are to be excluded. The reader will no doubt agree that a code for the refurbishment of all Irish dwellings needs to generate urgently and should be enforceable. Such a code should of course access the latest building physics knowledge and benefit from the testing of common Irish materials followed by simulation of their use in common dwelling types. It can then form the backbone of the national refurbishment effort and underpin all the work of different agencies and practices. Obviously the authors of that work need to be a respected body or an industry-wide group. This author, with Building Life Consultancy, is willing to talk to all bodies who wish to partake in such a valuable piece of work.

How the uninsulated, or under-insulated, building envelope should be prepared for an energy-efficient refurbishment must be included in the code. This is because the materials of an existing wall, whether cavity or single leaf, have a profound effect on how a dry-lining system applied will function for instance. Perhaps it is obvious that a solid brick wall will allow higher levels of vapour from the outside to reach the rear of the insulation than a rendered blockwork wall, but what of the effect of the original internal plaster and paint?

These can have a surprisingly significant effect. Modern chemical paints are diffusion-open due to their thinness but are generally closed to capillary action. The latter is a major way in which moisture moves through porous materials at times counter-acting a build-up of moisture driven there by vapour diffusion pressure. As the internal surface of the original wall is exactly where the dew point is most likely to occur in a drylined build-up it is precisely the point where one would want to encourage capillary action, not block it. Therefore the existing internal paint finish should be stripped off all walls before dry-lining, unless the architect is absolutely certain that all layers of paint are capillary-open.

With regard to existing plaster it depends where and what it is as to its appropriateness for insulating existing walls. An existing external lime render is generally acceptable because it’s more vapour permeable than most wall building materials. Sand-cement render on the outside of a wall made with cement mortar is also generally fine, but it can be problematic where it’s a repair to a wall that was built with lime mortar as the less permeable render can act as a barrier to vapour escaping. Having to re-render the outside of a wall in this way is a good example of how dry-lining can have hidden expenses if it’s to be done properly.

Lime plaster is again fine, as in most cases are sand-cement plaster, when retained on the inside face of the original wall. This is for two reasons: firstly, both are highly alkaline, which is useful at the dew point as alkalines can kill or at least limit mould. Secondly, the vapour permeability of the materials should be at least the same, but ideally greater, as vapour progresses outward through a wall. As this can’t be achieved from the inside surface of a drylined wall to the outside (as it could be for a new cavity wall or timber frame structure) it should at least happen from the dew point position onwards.

The one to watch for is existing gypsum plaster. This can ‘go to mush’ when trapped inside a drylined wall at the dew point. It’s also not alkaline and is food for mould. Therefore gypsum plaster should always be removed before dry-lining. In the case of a brick wall it must be replaced by an alkaline plaster, preferably lime. In the case of rendered blockwork we advise that at least an anti-mould or alkaline spray be used at that point to minimise the chance of mould growth, but better still an alkaline. <i>(Thanks to Lothar Moll of Pro-Clima for his insights on this subject.)</i>

Of course before the dry-lining is carried-out the ‘boots’, ‘cap’ and ‘coat’, should be in good order. No insulation system can deal with continuous moisture soaking into a wall. If there are ground drainage problems around the wall’s base (the ‘boots’) they have to be dealt with first. This goes for rising damp too, though the cause of that is as often the owner laying-in a concrete floor and damp proof membrane between the old single leaf walls. The ‘hat’ – the roof and all attendant gutters and downpipes – should also be in good working order. Ideally a drying-out time needs to be allowed. Lastly the ‘coat’ – the surface characteristics of the wall – needs to be considered. Re-pointing (with the right mortar) can significantly reduce driving rain ingress, as the mortar is and should be the weakest and most vapour permeable part of the wall but can be damaged, partially missing or inappropriately repaired in older buildings.

The ‘coat’ of brick may also need to be treated with a silane or siloxane impregnation to ensure the dry-lining does not result in an unacceptable increase in moisture content at the dew point. Note that impregnation of brick surfaces is frowned on in conservation circles in Ireland, and we believe the UK, but is considered best practice for normal and historic solid brick buildings in Germany. The next article in this series will discuss the difference between treatments and presents a series of compelling graphs generated by hygrothermal simulations for untreated brick walls, such as that shown in figure 8.

Figure 8: showing the damage the freeze-thaw cycle can do to a solid brick wall

Image: Fraunhofer Institute, IBP Holzkirchen

Interpretation of the results of a hygrothermal simulation

Numerical simulations can create hundreds of pages of data. It’s obviously critical that the key elements (that one is interested in examining on any particular occasion) are extracted from the ‘noise’ and correctly interpreted.

The documentation of the results may be followed by an interpretation of their practical meaning. This may be done by at least one of the following items:

• Comparing the resulting hygrothermal conditions with specified limits.

• Checking the risk of moisture accumulation by comparing the total moisture content in the construction after one cycle with the initial condition.

• Evaluating the moisture tolerance of the construction (drying potential).

• Feeding the transient results into a post process model (e.g. for mould or algae growth, rot, corrosion).

IS EN 15026, section 6.4.3

Wufi Online states that there are no general criteria which are applicable for every case. Different materials and different applications require different criteria. It does however give these guides:

1) The most important criterion: moisture must not accumulate over time. Water condensing in the building component must be able to dry out again. If the moisture content in your com- ponent keeps increasing – even slowly – you'll run into problems sooner or later.

2) The building materials which come into contact with moisture must not be damaged (such as by corrosion or mould growth).

3) Microbial growth may start below 80 per cent RH if the temperature is higher than 12°C.

4) If it takes longer than the first six months of a simulation for RH to drop below 80 per cent at a critical point in the build-up the specification is likely inappropriate.

5) It is advisable that, excluding the outer portion of the wall which is directly affected by driving rain but also has the best drying ability, RH levels in drylined walls should only ever rise above 80 per cent for short periods to ensure good drying: far better if they stay well below.

6) Wood should not exceed 20 mass-per cent of moisture (if temperatures are higher than 10°C) during a prolonged period; otherwise mould growth may result.

Wufi Online regards the following rules from the German standard DIN 4108-3 as useful though it adds that the Fraunhofer Institute staff considers the specific figures somewhat arbitrary given their own research:

a) The amount of condensing moisture in roof or wall assemblies must not exceed a total of 1.0 kg/m².

b) At interfaces between materials that are not capillary-active, no moisture increase exceeding 0.5 kg/m² is permissible. This is meant to avoid moisture running or dripping off, which could accumulate elsewhere and cause damage.

c) The moisture increase in wood must not exceed 5 mass-per cent; the moisture increase in materials made of processed wood must not exceed 3 mass-per cent.

Given the above it must be clear that the data outputted from a hygrothermal simulation do not come in the ‘pass’ or ‘fail’ format which is so simple and reassuring using the Glaser method. This means that a greater level of training and understanding is required to make assessments for systems that don’t suit the Glaser method, such as dry-lining. However numerical simulation under IS EN 15026 should not be the preserve of building physicists. In fact the availability of software like Wufi and Delphin is part of a concerted effort by building physicists to significantly increase the number of people in the construction industry who can evaluate materials at this level.

A reasonable understanding of the scientific units, material data and the vapour mechanisms involved is necessary to use the software and to understand if what is being outputted reflects a mistaken initial input or a key finding. Software with a good user interface, an extensive help file and an online forum – all of which Wufi Pro has – will do a lot to guide and educate the user. They also have courses: the first English language course in using Wufi was delivered last year in the Fraunhofer Institute in Holzkirchen, near Munich. This author attended. However courses have been run in various European countries, North America and Japan for many years. Alternatively you may wish to visit the Wufi website2 and download the free trial version of WUFI.

It is this author’s view that those creating codes of practice and regulations, NSAI Agrément, and architects who wish to control their specification closely need to learn and use numerical hygrothermal simulation. Outputs from simulations shown in the next Breaking the mould article will show why it’s so important. The technical department of all insulation suppliers need to move to supplying condensation risk analysis based on numerical simulation also. In fact, when standards are fully adhered to, they’re obliged to use numerical simulation in the case of dry-lining.

Bibliography

BS 5250 (2002), Code of practice for control of condensation in buildings

IS EN 13788 (2001), Hygrothermal performance of building components and building elements - Internal surface temperature to avoid critical surface humidity and interstitial condensation - Calculation methods

IS EN 15026 (2007) – Hygrothermal performance of building components and building elements — Assessment of moisture transfer by numerical simulation

Ashrae handbook – Fundamentals (2009), ASHRAE, USA

Künzel, H. M., (2000), Moisture risk assessment of roof constructions by computer simulation in comparison to the standard Glaser-method, Franuhofer IBP

Read the full Breaking the mould series

Related items

-

New Ejot profile cuts thermal bridging losses by 25mm insulation equivalent

New Ejot profile cuts thermal bridging losses by 25mm insulation equivalent -

Why airtightness, moisture and ventilation matter for passive house

Why airtightness, moisture and ventilation matter for passive house -

Ireland’s first 3D printed homes insulated with clay foam

Ireland’s first 3D printed homes insulated with clay foam -

Unilin Ireland launches embodied carbon report

Unilin Ireland launches embodied carbon report -

Ecological launches Retro EcoWall for internal wall insulation

Ecological launches Retro EcoWall for internal wall insulation -

Xtratherm name changes to Unilin

Xtratherm name changes to Unilin -

ProAir pioneers with EPDs for ventilation systems

ProAir pioneers with EPDs for ventilation systems -

Ecological Building Systems launch Retro EcoWall for internal wall insulation

Ecological Building Systems launch Retro EcoWall for internal wall insulation -

Kore launches low carbon EPS

Kore launches low carbon EPS -

Kilsaran gets NSAI cert for EWI to steel frame

Kilsaran gets NSAI cert for EWI to steel frame -

Let’s bring ventilation in from the cold

Let’s bring ventilation in from the cold -

45,000 more Irish homes face radon risk, new maps reveal

45,000 more Irish homes face radon risk, new maps reveal